10

G

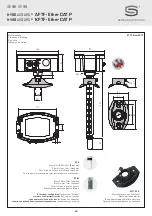

Installation and Commissioning

G

General notes

– This device may only be used in pollutant-free non-precipitating air without above-atmospheric or below-atmospheric pressure at the sensor

element.

– A suitable weather and sun protection hood must be used when installed outdoors.

– On outdoor and duct sensors, the sinter filter of the senor element protects the humidity sensor against potential dust exposure.

In case of pollution ⁄ contamination, this filter should be cleaned on a regular basis.

– Dust and pollution falsify measurement results and are to be avoided. Slight pollution and dust sediments can be removed by using compressed air.

– Touching the humidity element is under any circumstances to be avoided, as that would result in considerable mismeasurements.

– In case of pollution, we recommend cleaning and recalibration in the factory.

– In any case, the sensor must not get in contact with chemicals or other cleaning agents.

– The device operating range covers 10.0 ... 99.9 % r. H. Outside of that range, mismeasurements or increased deviations may occur.

– If this device is operated beyond the specified range, all warranty claims are forfeited.

Our “General Terms and Conditions for Business“ together with the “General Conditions for the Supply of Products and Services of the Electrical and

Electronics Industry“ (ZVEI conditions) including supplementary clause “Extended Retention of Title“ apply as the exclusive terms and conditions.

In addition, the following points are to be observed:

– These instructions must be read before installation and putting in operation and all notes provided therein are to be regarded!

– Devices must only be connected to safety extra-low voltage and under dead-voltage condition.

To avoid damages and errors at the device (e.g. by voltage induction) shielded cables are to be used,

laying parallel with current-carrying lines is to be avoided, and EMC directives are to be observed.

– This device shall only be used for its intended purpose. Respective safety regulations issued by the VDE,

the states, their control authorities, the TÜV and the local energy supply company must be observed.

The purchaser has to adhere to the building and safety regulations and has to prevent perils of any kind.

– No warranties or liabilities will be assumed for defects and damages arising from improper use of this device.

– Consequential damages caused by a fault in this device are excluded from warranty or liability.

– These devices must be installed and commissioned by authorised specialists.

– The technical data and connecting conditions of the mounting and operating instructions delivered together with the device are exclusively valid.

Deviations from the catalogue representation are not explicitly mentioned and are possible in terms of technical progress and continuous

improvement of our products.

– In case of any modifications made by the user, all warranty claims are forfeited.

– This device must not be installed close to heat sources (e.g. radiators) or be exposed to their heat flow.

Direct sun irradiation or heat irradiation by similar sources (powerful lamps, halogen spotlights) must absolutely be avoided.

– Operating this device close to other devices that do not comply with EMC directives may influence functionality.

– This device must not be used for monitoring applications, which serve the purpose of protecting persons against hazards or injury,

or as an EMERGENCY STOP switch for systems or machinery, or for any other similar safety-relevant purposes.

– Dimensions of housings or housing accessories may show slight tolerances on the specifications provided in these instructions.

– Modifications of these records are not permitted.

– In case of a complaint, only complete devices returned in original packing will be accepted.

These instructions must be read before installation and commissioning and all notes provided therein are to be regarded!

Notes regarding mechanical mounting and attachment:

Mounting shall take place while observing all relevant regulations and

standards applicable for the place of measurement (e.g. such as

welding instructions, etc.). Particularly the following shall be regarded:

– VDE ⁄ VDI directive technical temperature measurements,

measurement set - up for temperature measurements.

– The EMC directives must be adhered to.

– It is imperative to avoid parallel laying of current-carrying lines.

– We recommend to use shielded cables with the shielding being

attached at one side to the DDC ⁄ PLC.

Before mounting, make sure that the existing thermometer‘s technical

parameters comply with the actual conditions at the place of

utilization, in particular in respect of:

– Measuring range

– Permissible maximum pressure, flow velocity

– Oscillations, vibrations, shocks are to be avoided (< 0.5 g)

– Ensure not to kink or squash the sensor element

SAFETY REGULATIONS

These devices shall only be used for their intended purpose. Respective

safety regulations issued by the VDE, the states, their control authorities,

the TÜV and the local energy supply company must be observed. The

buyer has to ensure adherence to the building and safety regulations and

has to avoid all dangers of any kind. We do not assume any warranty for

faults or damages arising or resulting from improper use of our equipment

or from non-observance of operating instructions. These instruments

must be installed by authorised specialists only!

Preferably shielded cables should be used in order to prevent damages ⁄

errors. It is imperative to avoid laying parallel with current-carrying

lines. EMC directives must be adhered to.

Notes on commissioning:

This device was calibrated, adjusted and tested under standardised

conditions. When operating under deviating conditions, we recommend

performing an initial manual adjustment on-site during commissioning

and subsequently at regular intervals.

Commissioning is mandatory and may only be performed by qualified

personnel!