MAINTENANCE

86037580 GLIDE 01/03/07

4-9

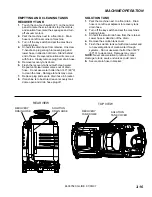

3.

Locate release lever on top of brush or pad

driver. With finger rotate release lever against

spring pressure counter clockwise. Brush/pad

driver will release and drop down.

4.

To reinstall, center the cut out of the release

lever plate on brush/pad driver to be installed

under the brush drive hub.

5.

Raise brush/pad driver up until assembly

contacts brush hub. Rotate slightly until driver

engages release lever plate.

6.

While holding upward pressure, rotate brush/pad

driver assembly clockwise. When fully engaged,

release lever plate will rotate under spring

pressure to lock assembly.

NOTE: Check that release plate is completely closed

and pad/brush is securely attached. Damage to

driver or brush could occur.

7.

Repeat the procedure for the opposite side of

the machine.

8.

The center brush should be changed from the

right side.

9.

Reinstall the side squeegees.

6.

VACUUM FILTER

The vacuum filter is located inside the recovery tank.

The vacuum filter prevents debris from entering the

vacuum motor. Daily remove and clean filter of any

debris for maximum airflow.

7.

FLOAT SWITCH

The float switch is located inside the recovery tank.

The purpose of the float switch is to notify the user

that the recovery tank is full. When the float switch is

activated, the scrub brush motors and solution flow

will stop, the scrub deck will raise, the squeegee will

rise after 60 seconds, and the vacuum motor will

turn off 10 seconds later.

8.

SOLUTION STRAINER

The solution strainer is located behind the right rear

wheel of the Glide. The solution strainer protects the

solenoid valve from debris. If there is little or no

solution flow to the ground, check the strainer for

debris. Drain the solution tank and clean the solution

strainer. To remove the strainer, turn the bottom part

of the strainer counterclockwise until the bottom is

separated. Clean out the debris from the wire mesh

and re-assemble. Make sure the O-ring gasket is in

place when re-assembled.

9.

BRAKE

(Refer to Brake Group in the Parts section of the

manual).

The brake pedal and parking brake operate the self-

centering front wheel disc brake. The disc and

caliper should be inspected every 200hours of

operation for cracks and disc wear. The brake

should be adjusted so that the disc pads are as

close to the disc as possible, without causing brakes

to drag.

BRAKE ADJUSTMENT

FOR SAFETY: Before leaving or servicing machine,

stop on a level surface, turn off machine and remove

key.

1.

Disconnect batteries from machine.

2.

Turn the steering wheel fully to the left.

3.

Locate the brake adjustment screw on the brake

caliper.

4.

Loosen the lock nut.

5.

Turn adjustment screw in until finger tight, then

back off 1/8 turn.

6.

Hold adjustment screw and tighten lock nut.

10.

STEERING CHAIN TENSIONER

(Refer to Steering Group in parts section of manual).

The steering chain transfers power from the steering

shaft to the drive wheel, controlling steering

response. Check the chain condition and tension

every 200 hours of operation. Proper chain tension

is important to maintain steering response. The

chain should deflect 1/16 in. Use a light spray lube if

needed.

STEERING CHAIN TENSIONER ADJUSTMENT

1.

Locate chain tensioner bolts.

2.

To increase tension, tighten lock nuts retaining

chain tension plate.

3.

To decrease tension, loosen lock nuts retaining

chain tension plate.

Icon appears on information screen 1 when

float switch is activated.