After choosing the required functions, fix the control support bracket that is

included in the delivery on the edge of the internal structure; always remember

to tighten the screw very well. Move the plastic cover up to the external edge

of the plated support

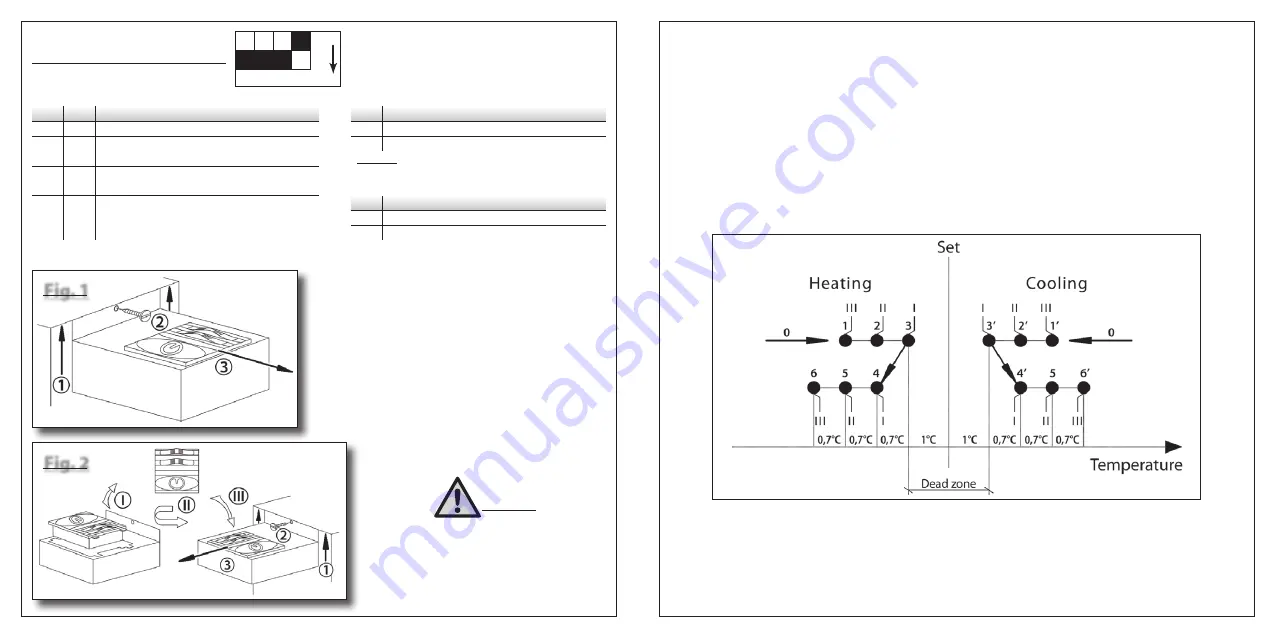

(Fig.1)

.

Insert the terminal board of the control (MC) into the terminal board of the

fan coil (MFC). Take care and tighten the screws of the terminal board.

Any TME minimum water probe must be connected to terminal board J6.

In the case of right water connections, the control must be installed on the

left of the Fan Coil.

In order to carry out this, follow the instructions of

Fig. 2

.

Since we have to change the side of the water connections in yard (possible

only for versions with centrifugal motor), the control must be installed in the

opposite side of the connections.

The connecting terminals, the cables and the fair-lead should

be fixed again on the opposite side, taking care in removing

the pre-sheared from the hole where should be inserted the

fair-lead.

Attention!

With the control unit on OFF,

the fan coil is still supplied with 230 V.

Before carrying out maintenance,

always disconnect from the voltage.

DEFAULT CONFIGURATION OF DIP SWITCHES:

DIP 1 DIP 2

D

escription

of

the

functions

ON

ON

T

hermosTaTic

conTrol

on

The

fan

OFF

ON

T

hermosTaTic

conTrol

on

The

valves

and

conTinuous

fan

operaTion

ON

OFF

s

imulTaneous

ThermosTaTic

conTrol

on

The

valves

and

fan

OFF

OFF

T

hermosTaTic

conTrol

on

The

valves

,

for

4-

pipes

sysTems

,

wiTh

auTomaTic

summer

/

winTer

cycle

swiTching

according

To

The

air

TemperaTure

,

wiTh

2°c

dead

zone

DIP 3

D

escription

of

the

functions

*

ON

v

ariaTion

of

nighT

Time

seT

poinT

(-3°c

winTer

, +3°c

summer

)

OFF

d

isabling

fan

coil

operaTion

DIP 4

D

escription

of

the

functions

ON

Tme

operaTion

in

The

cooling

cycle

OFF

Tme

operaTion

in

The

heaTing

cycle

ON

1 2 3 4

Fig. 1

Fig. 2

• TECHNICAL CHARACTERISTICS OF THE CONTROL UNIT

1) Power supply: 230V~

2) Thermostat control range from 12 to 32°C with differential 0.7°C

3) 2 x optoinsulated inputs for remote seasonal changeover (IN2); reducing set point reduction or turning off the control unit (IN1)

4) Probe status control: if the air probe is disconnected or short-circuited, the control unit switches to continuous operation (valve outputs energised

and fan on) and the red LED on the front of the control unit starts flashing; in the “automatic summer-winter switching” configuration, the control

unit is disabled and only the LED flashes.

• OPERATING PROGRAM WITH DEAD ZONE

Thermostatic control on the valves and continuous motor speed

Dipswitch 1 OFF

Dipswitch 2 OFF

With this program the Summer-Winter switching function is disabled

Operating diagram with dead zone:

Position 3 = Hot water solenoid valve OFF

Position 3’ = Cold water solenoid valve OFF

Position 4 = Hot water solenoid valve ON

Position 4’ = Cold water solenoid valve ON

Speed:

I = min.

II = med.

III = max.

* A

ttention

:

if

only

supplying

line

volTage

(l = 230v~)

To

The

Terminal

in1

Summary of Contents for 9060134

Page 13: ......