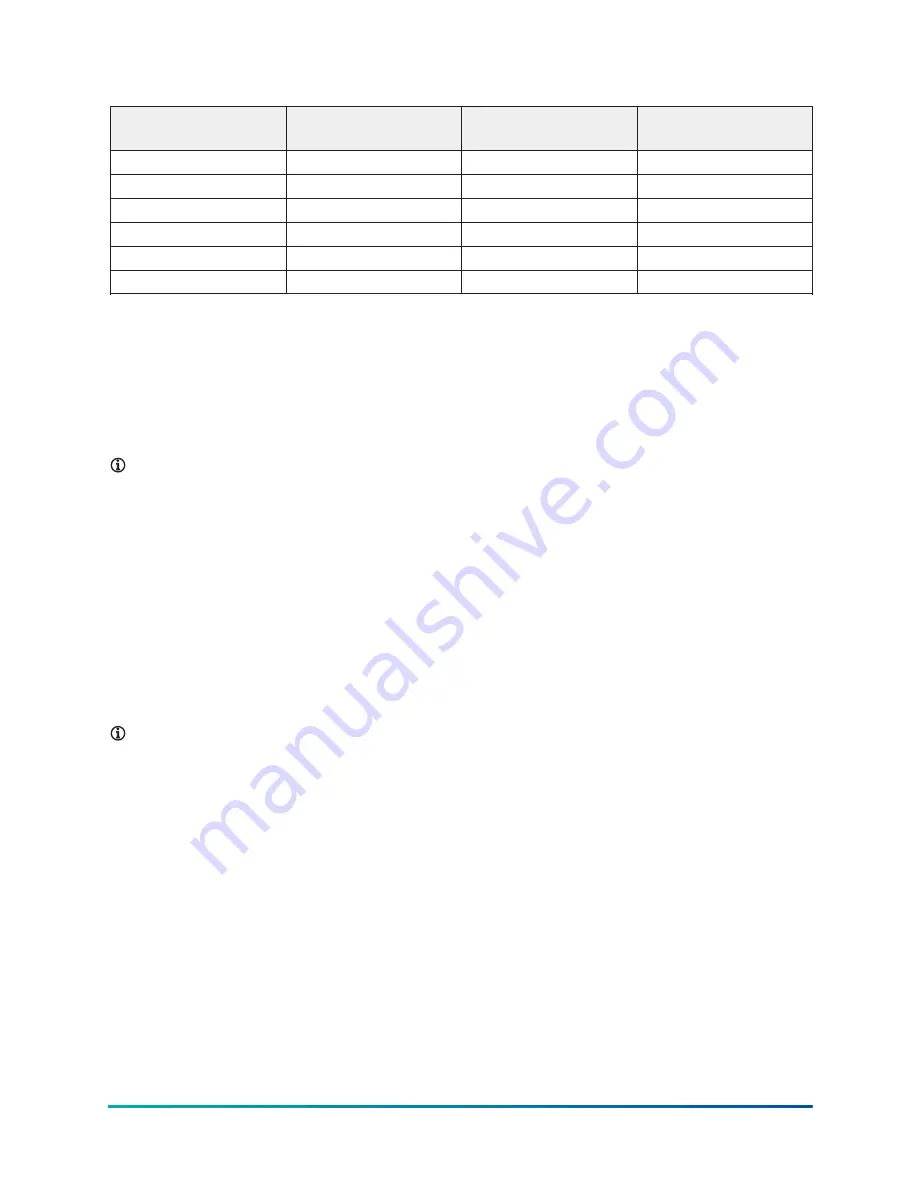

Table 18: Temperature classes - screw compressors

Temp. class

Max. surface temp.

Max. temperature of

oil to shaft seal

Min. ignition

temperature of oil

T1

450°C

380°C

500°C

T2

300°C

230°C

350°C

T3

200°C

130°C

250°C

T4

135°C

65°C

185°C

T5

100°C

30°C

150°C

T6

85°C

15°C

135°C

Initial start-up procedure

Only competent personnel with a thorough knowledge of refrigeration technique may start up the

unit. Prior to start-up, personnel must complete the prestart check.

When the checkpoints on the

installation

and

Preparation before start checklists

are complete, the

compressor unit is ready to start up. It is important that an adequate refrigerant load is available to

load test the unit at normal operating conditions.

Note:

During the initial start-up of the unit, it is imperative that the hand expansion valve on

the main oil injection line is fully open to ensure adequate oil flow. Using a demand oil pump, it

may be necessary to throttle in order to half open the valve before start-up.

There is an orifice installed in the compressor to control maximum oil flow. At initial start-up of the

compressor, the hand expansion valve must be fully open. After initial start-up of the unit, you must

adjust the hand expansion valve unless the unit is equipped with a motorised oil injection valve.

Motorised oil injection valve

Some units, usually if they have variable speed control (VSD), are equipped with a motorised valve

that controls the amount of oil being led to the rotors. This control uses the rotational speed to set

the appropriate opening degree of the valve and thereby regulate the amount of oil for the rotor

injection so that it follows the rpm of the compressor.

The motorised valve replaces the functionality of the hand expansion valve.

Note:

On units with both a motorised and a hand expansion valve on the oil injection inlet, the

hand expansion valve must be completely open unless otherwise agreed with the factory.

The factory settings of the motorised valve ensure that the valve is always a minimum 5% open

during operation. You must adjust the maximum opening degree according to the specific

application. You can make the adjustment at first start-up through the Unisab III display - and not

on the valve motor’s control display (ICAD).

Correct setting at first start-up

When the unit has achieved nominal operating conditions, adjust the parameter called Oil Flow

Open Max. through the Unisab III display. Increase the value if the discharge temperature is too

warm and decrease it if the temperature is too cold. Once you set the value, you do not need to

change it again unless the compressor should run at completely different operating conditions. To

determine the necessary discharge temperature, see the following method.

SAB 283-355 A-Frame OHU 6042 and OHU 7650 (including ATEX) Screw Compressor Unit

58