Page # 54

877 1st Ave. N.W. | Sioux Center, IA 51250 | Toll Free: 1.866.722.1488 | siouxautomation.com

OPERATION

REPLACEMENT PARTS

READ complete manual CAREFULLY

BEFORE attempting operation.

MON900645 2 HOSE MANUAL (AUGER DISCHARGE)

MON900644 2 HOSE MANUAL (SLIDE TRAY)

ITEM #

QTY

PART #

DESCRIPTION

1

2

BLT14X3NC

1/4X3 BOLT

2

2

BLT516X34NC

5/16X3/4 BOLT

3

2

HYD6602-8-8-8

ADAPTER TEE

4

4

HYD6801-6-8

REDUCER ELBOW

5

3

HYD6801-8-8

ELBOW

6

1

HYD6801-8-10

REDUCER ELBOW

7

3

HYD6801LL-8-8

LONG LEG ELBOW

8

1

HYD6801LL-8-10

LONG LEG ELBOW

9

1

HYDFC10

CHECK VALVE

10

1

HYDPMC9018

18” HYDRAULIC CYLINDER

11

1

HYDPMC9020

20” HYDRAULIC CYLINDER

12

2

HYDS7115

COUPLER

13

1

MON100806

VALVE MOUNT

14

1

MON701032

HYDRAULIC HOSE

15

2

MON701033

HYDRAULIC HOSE

16

2

MON701034

HYDRAULIC HOSE

17

1

MON701035

HYDRAULIC HOSE

18

1

MON800028

SELECTOR VALVE

19

2

NUT14NC

1/4” NUT

20

1

SAC74195

HYDRAULIC HOSE

21

1

SAC74197

HYDRAULIC HOSE

22

2

WSH14LOCK

1/4” LOCK WASHER

23

2

WSH516LOCK

5/16” LOCK WASHER

24

*

HYDPMCK9000

SEAL KIT FOR CYLINDER

ITEM #

QTY

PART #

DESCRIPTION

1

2

BLT14X3NC

1/4X3 BOLT

2

2

BLT516X34NC

5/16X3/4 BOLT

3

4

HYD6801-6-8

REDUCER ELBOW

4

3

HYD6801-8-8

ELBOW

5

3

HYD6801LL-8-8

LONG LEG ELBOW

6

1

HYDPMC8408

8” HYDRAULIC CYLINDER

7

1

HYDPMC9020

20” HYDRAULIC CYLINDER

8

2

HYDS7115

COUPLER

9

1

MON100806

VALVE MOUNT

10

1

MON700809

HYDRAULIC HOSE

11

1

MON700810

HYDRAULIC HOSE

12

1

MON701032

HYDRAULIC HOSE

13

2

MON701034

HYDRAULIC HOSE

14

1

MON701035

HYDRAULIC HOSE

15

1

MON800028

SELECTOR VALVE

16

2

NUT14NC

1/4” NUT

17

2

WSH14LOCK

1/4” LOCK WASHER

18

2

NUT516LOCKNC

5/16” LOCK NUT

19

*

HYDPMCK9000

SEAL KIT FOR CYLINDER

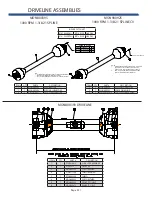

DISCHARGE HYDRAULIC ASSEMBLIES

C4

18

P1

P2

C2

C3

C1

C5

C6

7

ALWAYS RELEASE HYDRAULIC OIL

PUNCTURE OR CUT SKIN RESULTING

21

IN SERIOUS INJURY OR DEATH.

PRESSURE BY (1) DISCONNECTING

ALL TRACTOR LINES AND PTO, AND

(2) PROPERLY RELIEVING OIL PRESSURE.

17

DISCHARGE

CYLINDER

14

12

CYLINDER

12

DOOR

TO TRACTOR

16

P1

P2

C3

C2

C1

C4

8

5

7

5

5

15

MOUNT DISCHARGE LIFT CYLINDERS WITH PORTS

2.

TOWARD WAGON SIDE.

7

3

6

9

3

C5

C6

16

4

4

4

4

20

11

10

15

WARNING!

HYDRAULIC OIL PRESSURE CAN

NOTES:

CONNECT CORRESPONDING LETTER TO PORTS.

1.

13

C2

15

P1

C4

P2

C3

C1

11

6

7

PRESSURE BY (1) DISCONNECTING

ALL TRACTOR LINES AND PTO, AND

(2) PROPERLY RELIEVING OIL PRESSURE.

14

DISCHARGE

CYLINDER

12

8

CYLINDER

8

DOOR

TO TRACTOR

13

P1

P2

C3

C2

C1

C4

4

4

5

4

5

ALWAYS RELEASE HYDRAULIC OIL

IN SERIOUS INJURY OR DEATH.

PUNCTURE OR CUT SKIN RESULTING

MOUNT DISCHARGE LIFT CYLINDERS WITH PORTS

2.

TOWARD WAGON SIDE.

5

C5

13

3

3

3

3

10

WARNING!

HYDRAULIC OIL PRESSURE CAN

NOTES:

CONNECT CORRESPONDING LETTER TO PORTS.

1.

9

Summary of Contents for Turbo-Max 6100 Series

Page 66: ......