Page # 27

877 1st Ave. N.W. | Sioux Center, IA 51250 | Toll Free: 1.866.722.1488 | siouxautomation.com

OPERATION

REPLACEMENT PARTS

READ complete manual CAREFULLY

BEFORE attempting operation.

877 1st Ave. N.W. | Sioux Center, IA 51250 | Toll Free: 1.866.722.1488 | siouxautomation.com

OPERATION

REPLACEMENT PARTS

READ complete manual CAREFULLY

BEFORE attempting operation.

LUBRICATION

LUBRICATION

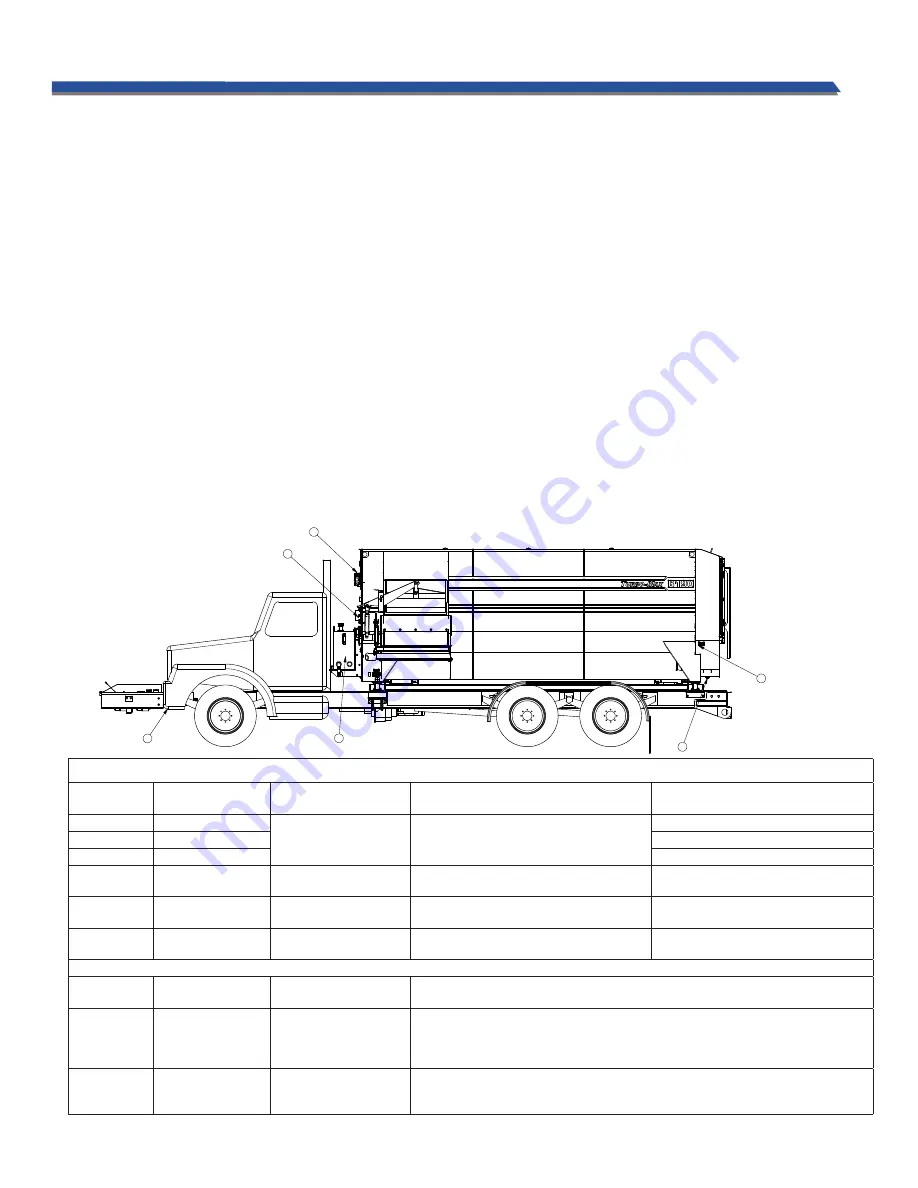

ITEM

LUBRICATION

INTERVAL

CAPACITY

OIL TYPE

LOCATION

1

8 HOURS

HIGH QUALITY MULTI PURPOSE GREASE

FRONT AUGER & REEL BEARINGS

2

8 HOURS

REAR AUGER & REEL BEARINGS

3

8 HOURS

DRIVELINE UNIVERSAL JOINTS

4

50 HOURS

APPROX. 22 GALLONS

GOOD QUALITY HYDRAULIC OIL

OIL BATH OIL (CHECK LEVEL)

REPLACE ANNUALLY

5

1000 HOURS

APPROX. 80 GALLONS

ISO 46 HYDRAULIC OIL OR EQUIVALENT

HYDRAULIC OIL (CHECK LEVEL)

REPLACE ANNUALLY

6

1000 HOURS

7 PINTS

MOBIL SCH629 OR EQUIVALANT

PLANETARY (CHECK LEVEL)

REPLACE ANNUALLY

FILTERS

CHANGE

INTERVAL

FILTER PART#

LOCATION

AUXILIARY

CIRCUIT

FIRST 50 HRS THEN

500 HRS OR

ANNUALLY

SAC# HYD1A9021

FORCE #F3653-10C

NAPA# 1551

SINGA# AE10

RIGHT HAND SIDE OF HYDRAULIC TANK ON RETURN LINE

CHARGE

PUMP

FIRST 20 HRS,

NEXT 100 HOURS,

THEN 250 HRS

SAC# HYDP176566

FRONT OF TRUCK BY HYDROSTATIC PUMPS

•

The operator is responsible for routine maintenance and must carry out the following activities.

•

It is extremely important that the following lubrication schedule be followed:

Bearings: use a good quality

multipurpose grease. Replace all damaged or missing grease zerks immediately. Always clean zerks before using

grease gun. Pump the grease in slowly until a slight bead forms around the bearing seals. Once a month check lines

and connections on grease banks for leaks.

•

Oilbath Oil:

Use a good high quality universal oil. Use an oil that meets or exceeds hydraulic oil grade. Fill to a level

just above the lowest roller chain link in the oilbath. Change yearly or whenever contaminated.

•

Planetary Oil:

After a brief operating period of about 100 hours (breaking in), change the oil in the gear units. Check

that there are no metallic parts with unusual dimension in the magnetic plug of the gear unit. Change the oil in the

gear unit while it is hot so that it is easier to drain. Subsequent oil changes will be made every 1000 hours of operation

or, in any case, each year. Use synthetic ISO MOBIL SCH629 oil. (or equivalent ISO VG 220 gear oil)

DO NOT MIX OILS!

Periodically check the levels (about once a month) and top off if necessary. It is recommended to keep a chart that will

be filled out and updated each time maintenance is performed. For long periods out of service, completely fill planetary

with oil to prevent gears and bearings from corrosion.

•

Planetary Oil Change Instructions:

The planetary is equipped with oil level, breather, filler and drain plugs and their

position changes according to the installation configuration. Unscrew the drain plug and the filler plug to help drain

the oil from the gear unit. Once the oil has been emptied, replace the drain plug.

•

Filling instructions:

Unscrew the level and filler plugs and add gear oil until the oil flows out of the oil level hole.

Replace the plugs. Turn the gear unit a few times to eliminate any air pockets and then check the level again.

•

Hydrostatic Oil:

Replace the hydrostatic oil every 1000 hours or annually (approximately 80 gallons).

•

Hydrostatic Oil Filter:

Replace the oil filter after the first 50 hours of operation. The filter should then be replaced

whenever the filter indicator shows replacement is necessary or after every 250 hours of operation or annually.

•

Before operating a new mixer,

the roller chains should be liberally lubricated and then the unit operated under a no-

load condition. This break-in period will allow the roller chains to be thoroughly lubricated and thus minimize heat-up

during operation.

6

1

3

5

4

2

Summary of Contents for TURBO-MAX 6190

Page 64: ......