© 2018

Step 1 of 2

Order #XXXXX

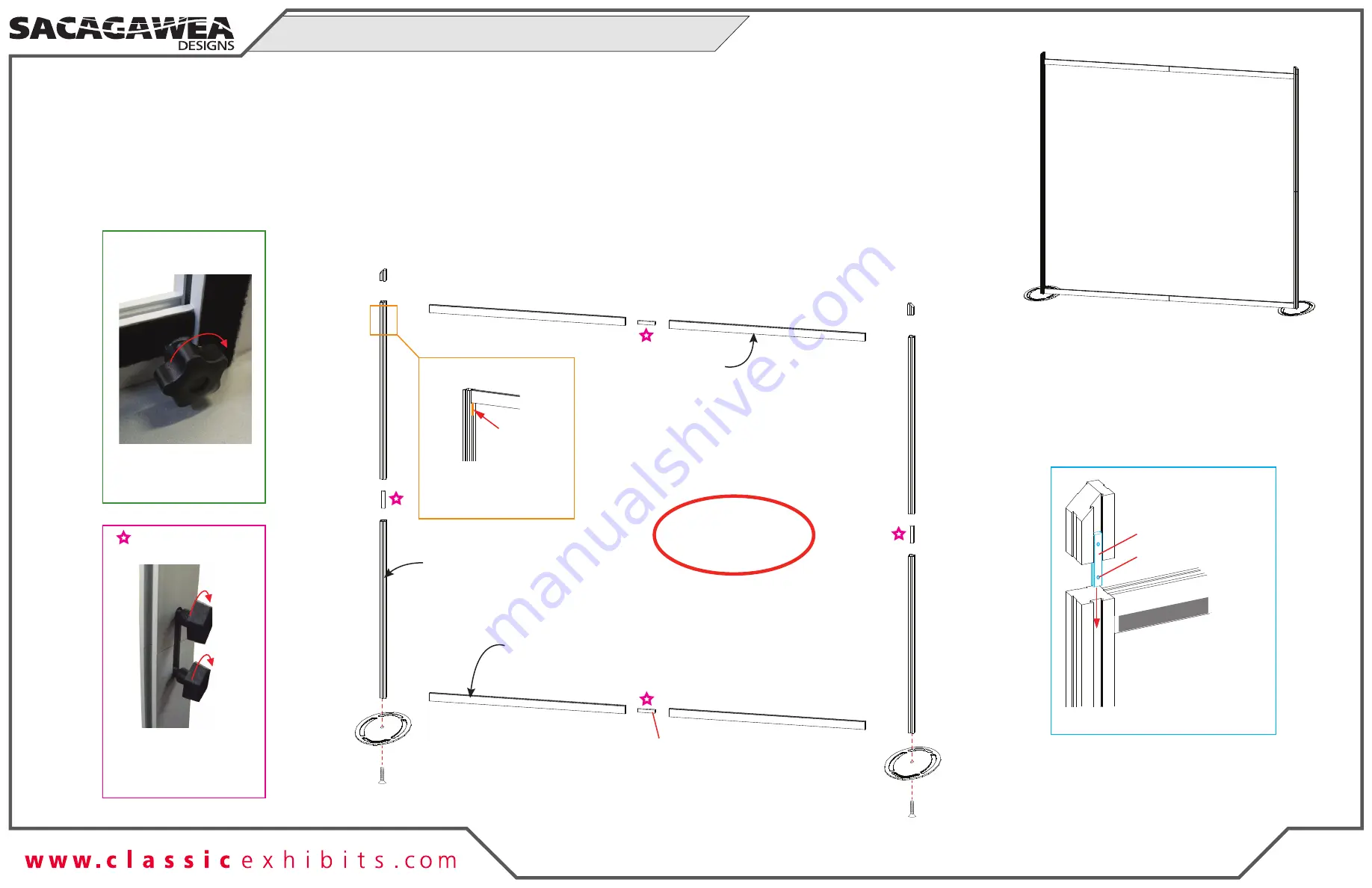

VK-1223 Assembly

Item

1

2A/2B

3A/3B

4A/4B

5A/5B

6A/6B

Description

Base Plate

42” Vertical Extrusion

42” Vertical Extrusion

45” Horizontal Extrusion

45” Horizontal Extrusion

2.5” Angle-Cut Vertical

Qty.

2

1/1

1/1

1/1

1/1

1/1

Completed Backwall

Front View

Connection Bar

1

1

3A

3B

2A

Bolt

Bolt

2B

B

B

4B

4A

5B

5A

A

A

Velcro:

Back/Bottom Edges

of Top Horizontals.

Velcro

:

Back/Top Edges

Bottom Horizontals.

6A

Steps:

1) Attach base plates [1] verticals [2A] & [3A], using bolts.

2) Connect verticals [2A] [2B] and [3A] [3B], using connection bars [B].

See

Straight Connection with Knobs

detail.

3) Connect horizontals [4A] [4B] and [5A] [5B], using connection bars [A].

See

Straight Connection with Knobs

detail.

4) Connect assemblies [2A/2B] and [3A,3B] with assemblies [4A,4B] and [5A,5B].

See

Corner Connection with Knob

detail.

5) Connect angled verticals [6A] to [2B] and [6B] to [3B].

See

2.5”h Angle-Cut Vertical Attachment

detail.

6) Attach graphic to

Velcro

on back of assembled Backwall.

*

*

Velcro

:

Back/Inside Edges

of all Verticals.

6B

Set Screw

Connector

2.5”h Angle-Cut

Vertical Attachment

Back View of Backwall

Insert connector into groove

of vertical extrusion, then

tighten set screw to secure.

*

Velcro

*

*

*

*

Velcro

on extrusions

must face to

BACK

of

assembled Backwall.

Horizontal Placement

Stopper

Set upper horizontals

on top of stopper,

located on verticals.

Slide connection bar between

extrusions, then turn knobs

clockwise to tighten lock.

Straight Connection

with Knobs

Do not over tighten Knobs

Knob

Knob

Corner Connection

with Knob

Turn knob clockwise

to tighten lock.

Do not over tighten Knobs

Knob

*