Instruction manual V 2.3

25

PWM 230 - PWM 400 - PWM 400/7.5

Instruction manual

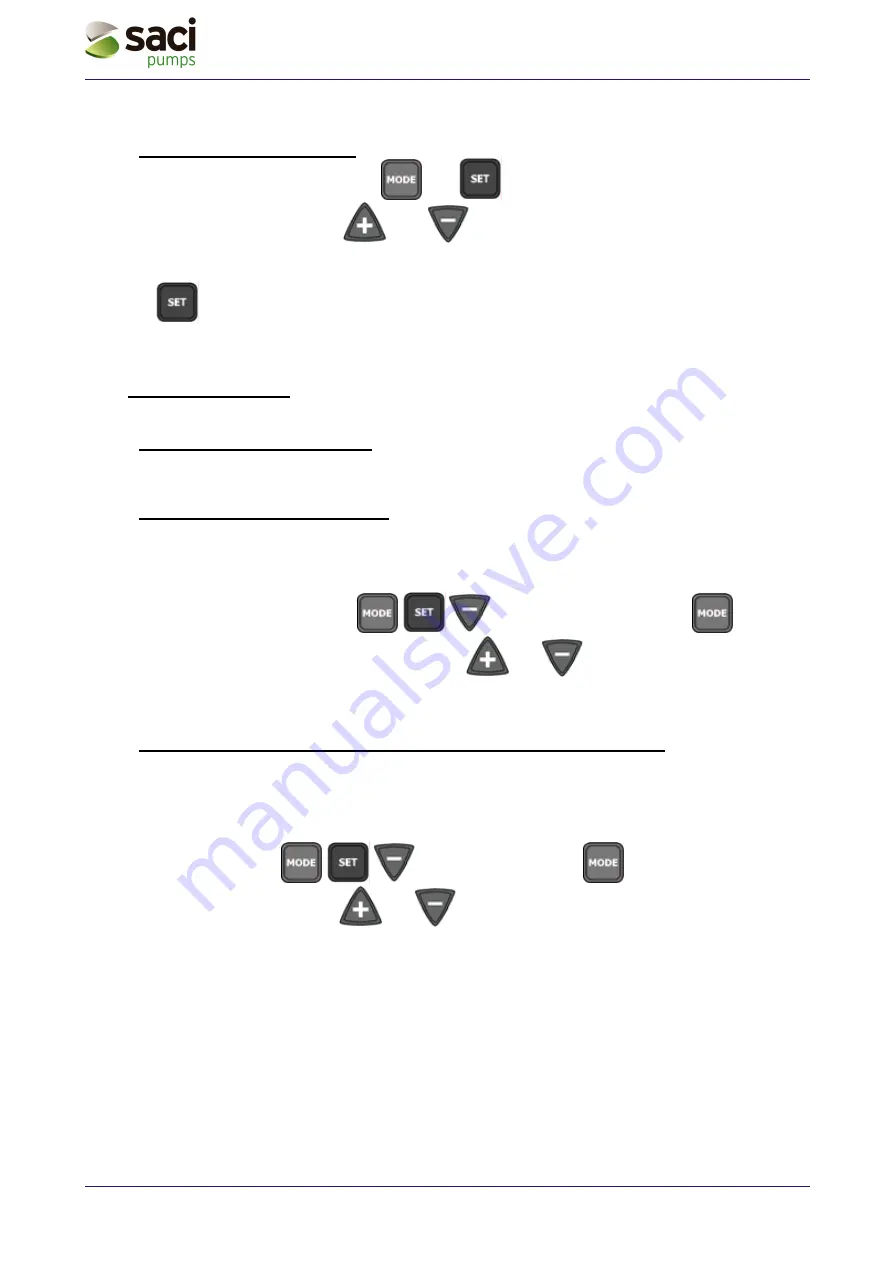

d) Setting the set-point pressure.

From normal operation status keep the

and

keys both pressed until “SP” appears on the

display. In these conditions the

and

keys allow to increase or decrease the desired

pressure value.

Set-point pressure may range from 1,0 to 15 bar.

Press

to go back to normal operation status.

4.2 Typical

installation

4.2.1

Installation with an electro pump

Power

the PWM and follow the procedures explained in sec. 4.1 (see also Figure 1)

4.2.2

Installation with two electro pumps

•

Connect two PWMs with the provided cable using the J9 connector (see sec. 2.5.1).

•

Power the PWM

•

Follow steps a), b), c), of sec. 4.1with each device (rC, Fn, rt)

•

On one of the two devices press

for 5 seconds, then press the

key

multiple times until “Ad” is displayed and with the

and

keys set Ad = 1

•

On the other PWM set Ad = 2, as done above with the first PWM

•

Set the set-point pressure only on one of the two PWM’s as described in point d) of sec. 4.1.

4.2.3

Installation with 1, 2, 3 or 4 electro pumps and “Da Vinci” controller board

•

Connect the PWM with the provided cable to the “Da Vinci” controller board (see sec. 2.5.2).

•

Power the PWM and the controller board

•

Follow steps a), b), c), of sec. 4.1 with each PWM (rC, Fn, rt)

•

On each PWM press

for 5 seconds, press the

key multiple times until

“Ad” is displayed and with the

and

keys set Ad = 3

•

Set the set-point pressure from the controller board (see “Da Vinci” user instr. Manual)