Instruction manual V 2.3

39

PWM 230 - PWM 400 - PWM 400/7.5

Instruction manual

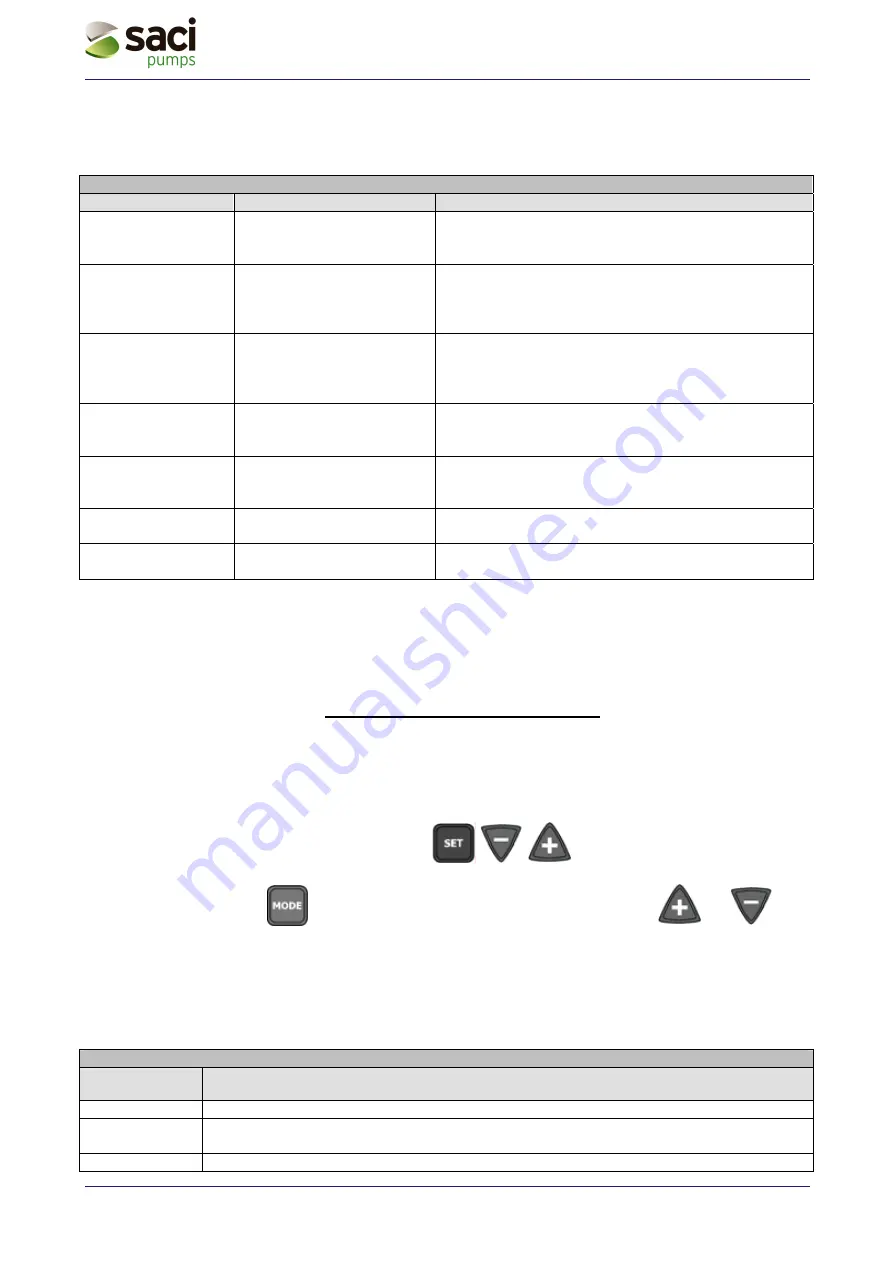

The following table shows the procedures performed by PWM when different error conditions occur:

Automatic reset of error conditions

Display indications

Description

Sequence of automatic reset

BL

Blockage due to lack of

water

- One attempt every 10 min. for a total of 6 attempts

- One attempt every 1 hour for a total of 24 attempts

- One attempt every 24 hours for a total of 30 attempts

LP

Blockage due to low supply

voltage (lower than 184V for

PWM 230 and 320V for

PWM 400)

- Recovery happens when line voltage returns to be

higher than 184 V for PWM 230 and than 320 V for

PWM 400

HP

Blockage due to high supply

voltage (higher than 264V

for PWM 230 and 457V for

PWM 400)

- Recovery happens when voltage returns to be lower

than 264 V for PWM 230 and lower than 457 V for

PWM 400

ot

Blockage due to overheating

of the power stages (tE >

100°C)

- Recovery happens when the power stages’

temperature falls below 85°C

ob

Blockage due to overheating

of the printed circuit

(bt > 120°C)

- Recovery happens when the printed circuit’s

temperature falls below 100°C

oC

Blockage due to overcurrent

of the pump

- One attempt every 10 min. for a total of 6 attempts

oF

Blockage due to overcurrent

in the output stages

- One attempt every 10 min. for a total of 6 attempts

Table 14: Automatic reset of error conditions

7

SWITCHING TO MANUAL MODE

A greater flexibility is achievable by using the system in manual mode. In this operating mode the PWM

performs no pressure control action and the user can force it to perform some actions, according to the

possibilities listed in this chapter.

To access to this operating mode, hold down the

keys simultaneously for at least 5

seconds. Activation of manual mode is signalled by a blinking display.

In this operating mode the

key allows to scroll through all parameters and the

and

keys

increase and decrease the modifiable parameters.

The functions of the keys and their combinations are summarized in Table 15 and explained in the sections

that follow.

Warning

: In this mode all controls and protection systems of the PWM are disabled and any device

connected to the PWM (PWM or controller board) cannot control regulation.

Use of the keys.

Pressed keys

Action

“SET” & “-” & “+“ Press them together until the display shows “MA” (5 sec.)

“+”

Increases the parameter’s value if it does not yet equal the maximum allowed one (only

frequency and rotation direction of the pump)

“-“

Decreases the parameter’s value if it does not yet equal the minimum allowed one (only