Instruction manual V 2.3

44

PWM 230 - PWM 400 - PWM 400/7.5

Instruction manual

9 APPENDIX

9.1 Pressure

loss

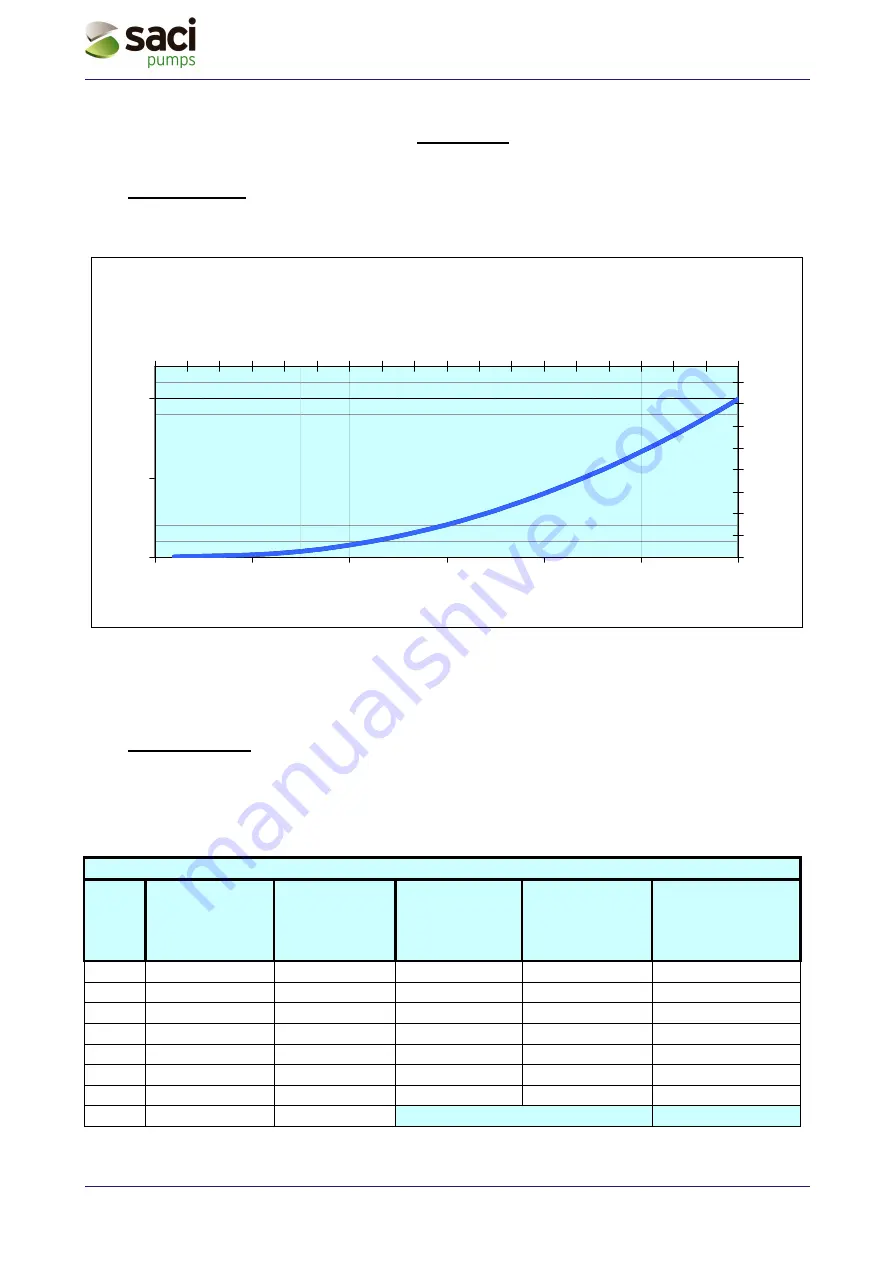

Pressure loss diagram of PWM

Figure 16: PWM’s pressure loss

9.2 Energy

saving

Use of the PWM system instead of traditional On/Off systems drastically reduces energy consumption. To

show this, an example that represents the consumption of a 1,5 kW pump in the two cases follows. The

comparison is done with the same yearly flow demand.

Test performed with a 1,5 KW electro pump and prevalence set to 30 mH2O

Flow

(l/min')

Statistic use of

flow

Direct insertion

consumption

(KW)

Consumption

with PWM (KW)

Power difference

(KW)

Energy saved in one

year (8760 hours)

(Kwh)

5 20% 1,295 0,185 1,110

1.945

10 40%

1,388 0,555

0,833

2.917

20 20%

1,480 0,740

0,740

1.296

40 9%

1,573 1,110 0,463

365

70 6%

1,794 1,570 0,224

118

100 5%

1,850 1,850

0,000

0

Total yearly saving (KWh)

6.641

Table 17: Energy saving

Pressure loss on PWM

0

5

10

0

50

100

150

200

250

300

Flow (l/min)

Pr

essur

e

(m

H2O)

0

2

4

6

8

10

12

14

16

0

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15 16 17 18

Flow (sqm/h)

Pr

essur

e

(PSI)