8 - 13

176.12

.A03

Revision 01 Date 14.11.2001

MAINTENANCE

8

8.1.2.4

Disassembling the forming plunger

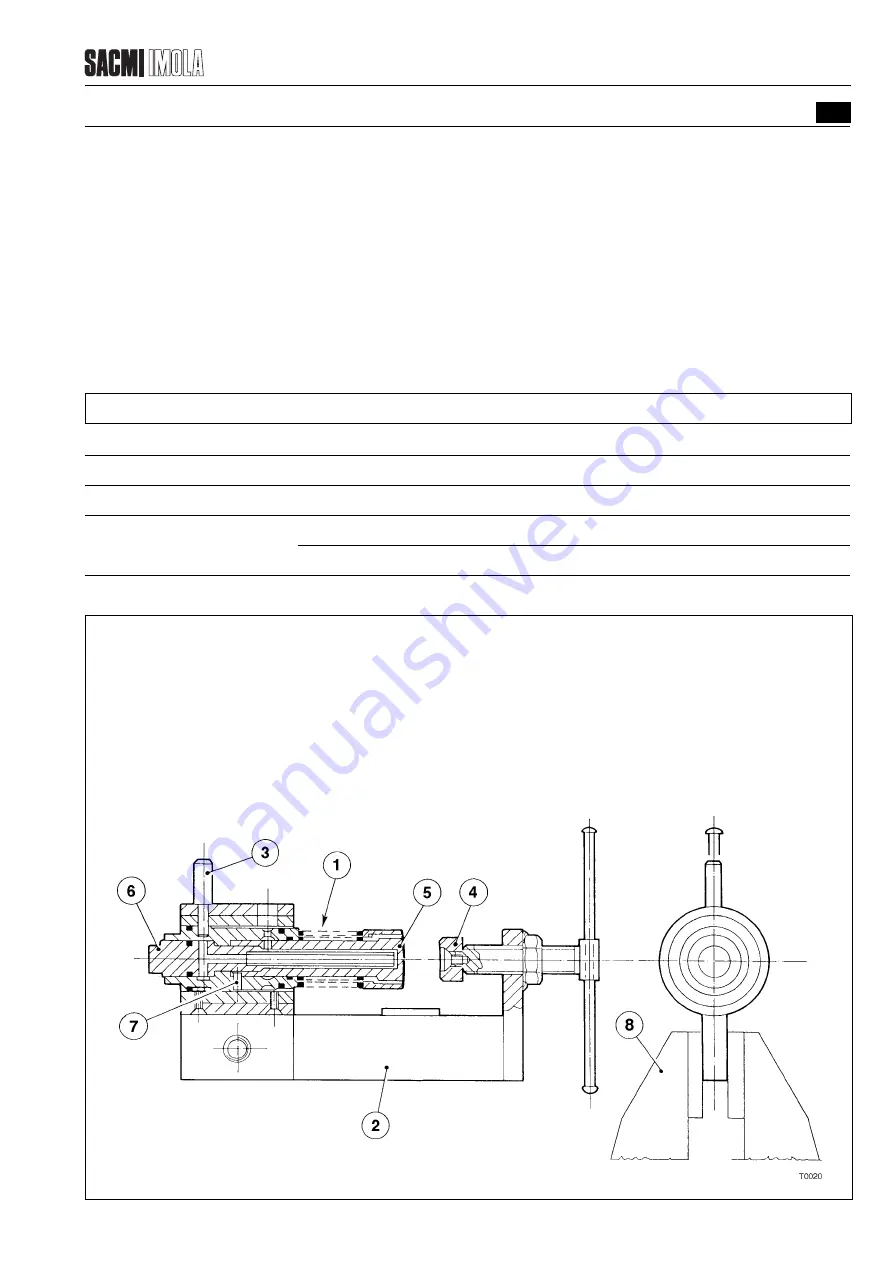

After removing the forming plunger from the drum , proceed as follows to disassemble it:

- Place the forming plunger (1) in the fixture (2).

- Insert the pin (3) in the reference hole in the plunger.

- Place the fixture in a vice (8) as shown in the diagram.

- Bring the jaw (4) into contact with the central plunger (5).

- Loosen the screw (6).

- Loosen the jaw (4).

At this point the components are loose and can be disassembled. To install, proceed in the reverse order making sure

that the cavity in the central plunger (5) coincides with the reference pin (7).

NOTE: The screw (6) must be tightened with a torque wrench set as indicated in the chart below.

Machine

Thread diameter of the plunger fixing screws

Tightening torque

PMV224

M12x1

3.5 daNm

PMV238

M16x1

10 daNm

M20x1

15 daNm

FIGURE 8.1.2.4 - DISASSEMBLING THE FORMING PLUNGER

1

Forming plunger

2

Fixture

3

Fixture reference pin

4

Jaw

5

Central plunger

6

Plunger set screw

7

Plunger reference pin

8

Bench vice

Summary of Contents for PMV 224

Page 2: ...TABLE OF CONTENTS 176 12 A03 0 2 Revision 01 Date 14 11 2001 ...

Page 4: ...TABLE OF CONTENTS 176 12 A03 0 4 Revision 01 Date 14 11 2001 ...

Page 34: ...2 22 176 12 A03 Revision 01 Date 14 11 2001 2 MAIN FEATURES ...

Page 42: ...3 8 176 12 A03 Revision 01 Date 14 11 2001 SAFETY EQUIPMENT AND PRECAUTIONS 3 ...

Page 64: ...5 4 5 START UP 176 12 A03 Revision 01 Date 14 11 2001 ...

Page 70: ...6 6 176 12 A03 Revision 01 Date 14 11 2001 6 OPERATING INSTRUCTIONS ...

Page 126: ...8 30 176 12 A03 Revision 01 Date 14 11 2001 8 MAINTENANCE ...

Page 128: ...9 2 176 12 A03 Revision 01 Date 14 11 2001 9 DECOMMISSIONING ...