13

XL-AS20012BM-en-US Rev B · 2014-05-28 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND,

SAF, and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Pre-Operation Information

11. Pre-Operation

NOTE:

In the United States, workshop safety requirements

are defined by federal and/or state Occupational

Safety and Health Act. Equivalent laws may exist

in other countries. This manual is written based

on the assumption that OSHA or other applicable

employee safety regulations are followed by the

location where work is performed.

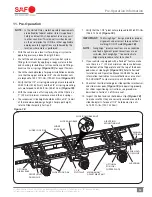

1. With the vehicle on a level surface, bring air system to

operating pressure, above 85 psig/5.9 bars.

2. Shut off the vehicle and inspect all air control system

fittings for air leaks by applying a soapy water solution

and checking for bubbles at all connections and fittings.

Examine the air springs

(Figure 18)

for equal firmness.

3. Check the shock absorbers for proper installation and make

sure that the upper and lower 3/4" shock absorber nuts

BSFUPSRVFEUPGUMCT /tN

(Figure 18)

.

4. Verify that the 1/2" air spring mounting nuts are torqued to

GUMCT /tNBOEUIFBJSTQSJOHNPVOUJOH

OVUTBSFUPSRVFEUPGUMCT /tN

(Figure 18)

.

5. With the suspension at full capacity, check that there is a

1" (25 mm) minimum clearance around the air springs.

6. The suspension’s ride height should be within ±1/4" (6 mm)

of the recommended design height. For proper height,

refer to Slider Assembly Section 8.

7. Verify that the 1-1/8" pivot nut are torqued to 550-600 ft.-lbs.

/tN

(Figure 18)

.

IMPORTANT:

The

SwingAlign

™

design maintains proper

alignment under correct torque without

welding; DO NOT weld

(Figure 18)

.

NOTE:

SwingAlign

™

pivot connections are on roadside

and fixed alignment pivot connections are on

curb-side. For SwingAlign

™

Connection Axle

Alignment procedure, refer to Section 9.

8. If your vehicle is equipped with a PosiLok

™

feature, make

sure there is a 1" (25 mm) minimum clearance between

the bottom of the flipper plate and the top of the beam

pad when at ride height

(Figure 18)

; Refer to PosiLok

™

Installation and Operation Manual XL-AR408 for more

information. Available at www.safholland.us or contact

SAF-HOLLAND

®

Customer Service at 888-396-6501.

9. Check that the slider locking pins, slider pull-bar mechanism,

and slider wear pads

(Figure 18)

are operating properly.

For slider repositioning instructions, see procedures

described in Section 12 of this manual.

10. Inspect the front and rear hold down clips

(Figure 18)

to make sure that they are correctly secured around the

slider body rails. Torque all 1/2" hold down clip nuts

UPGUMCT /tN

Figure 18

AIR SPRING

MOUNTING NUT

SHOCK ABSORBER NUT

REAR HOLD

DOWN CLIP

MANUAL

STOP BAR

OPTIONAL

AIR RELEASE

SHOCK ABSORBER

SLIDER

BODY RAILS

SLIDER LOCK PINS

AIR SPRING

OPTIONAL

POSILOK

™

FLIPPER PLATE

SWINGALIGN

™

ADJUSTMENT NUT

1- 1/8"

PIVOT NUT

FRONT HOLD

DOWN CLIP

SLIDER LOCK PINS