7

XL-AS20012BM-en-US Rev B · 2014-05-28 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND,

SAF, and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Welding Standards

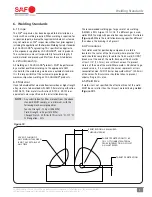

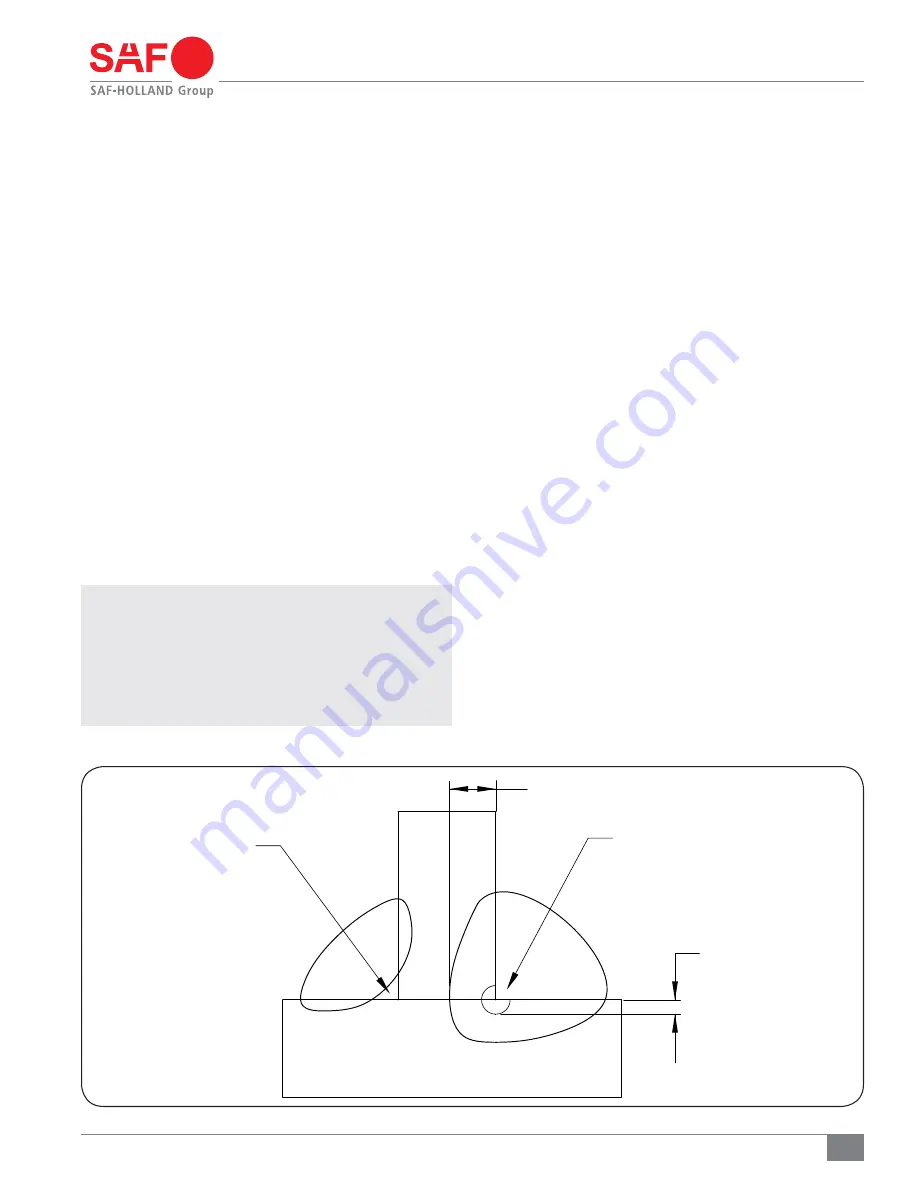

Figure 10

LACK OF FUSION OF

ANY KIND IN THIS AREA

IS NOT ACCEPTABLE AT

ANY TIME

PENETRATION AS MEASURED

THROUGH SEAM

TARGET PENETRATION TO BE

10% OF THINNEST MATERIAL

FROM INTERSECTION OF FILLET

AS ILLUSTRATED

TARGET PENETRATION

6. Welding Standards

6.1 Scope

The SAF

®

suspension has been designed to be installed on a

trailer with no welding required. When welding is required for

suspension repairs, observe the requirements below. Customers

may not weld on an SAF

®

suspension without our prior approval,

including the application of the American Welding Society standards

by SAF-HOLLAND

®

engineering. This specification applies to

all components supplied by SAF-HOLLAND

®

, and its products.

The customer assumes all responsibility for weld integrity if

weld material and procedure differ from those listed below.

6.2 Workmanship

All welding on SAF-HOLLAND

®

products MUST be performed

by a welder qualified according to the appropriate AWS

standard for the weld being made or an equivalent standard.

It is the responsibility of the customer to provide good

workmanship when welding on SAF-HOLLAND

®

products.

6.3 Material

Items to be welded that are made from low carbon or high-strength

alloy steel are to be welded with AWS filler metal specification

AWS A5.18, filler metal classification ER-70S-3, ER-70S-6 or

equivalent unless specified on the installation drawing.

NOTE:

Any substitution for filler material from the above

standard MUST comply, as a minimum, with the

following mechanical properties:

Tensile Strength - 72k psi (496 MPa)

Yield Strength - 60k psi (414 MPa)

$IBSQZ7/PUDIGUMCT /tNBU

o

F (-17.7

o

C)

% Elongation - 22%

The recommended welding gas for gas metal arc welding

(GMAW) is 90% Argon / 10% CO2. If a different gas is used,

welds MUST comply with penetration requirements illustrated

(Figure 4)

. Where the installation drawing specifies different

than above, the drawing shall prevail.

6.4 Procedures

Tack welds used for positioning components are to be

located in the center of the final weld, where practical. Tack

weld should be completely fused to the finish weld. DO NOT

break arc at the end of the weld. Back up all finish welds

at least 1/2" (12.7 mm) or a sufficient amount to prevent

craters at the end of the weld. Where weld is illustrated to go

around corners, it is assumed the corner represents a stress

concentration area. DO NOT start or stop weld within 1" (25.4 mm)

of the corner. Particular care should be taken to prevent

undercutting in this area.

6.5 Weld Size

If weld size is not specified, the effective throat of the weld

MUST be no smaller than the thinnest material being welded

(Figure 10)

.