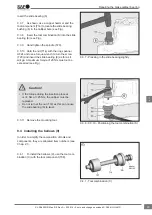

Check the adjustment thread (16)

7.1.5 Insert the new brake pad (12

2

) into the out-

er calliper shaft so that the threaded pipes cannot

be unscrewed from the bridge. Unscrew the thread-

ed pipes by turning the adapter (61) (see Fig.).

Do not fully unscrew the threaded pipes (16) from

the bridge as this can impair synchronisation,

necessitating complete replacement of the brake

calliper.

Danger !

With the brake calliper removed:

7.1.6 If the brake calliper has been removed or is

on the workbench, a suitable spacer (S) (=70 mm)

must be inserted when unscrewing the threaded

pipes (16) to prevent the threaded pipes (16) from

being fully removed (see Fig.).

Check for corrosion and damage whilst unscrewing

the thread of the threaded pipes (16). If ingressed

water or corrosion is detected, the brake calliper

must be replaced (see Chap. 8).

7.2 Removing and installing the inner

seal (22)

7.2.1 Unscrew the threaded pipes (brake calliper

installed)

7.2.2 Clean the inner seal area (22) and lever out

the inner seal (22) with a screwdriver (B) (see Fig.).

The seal (X) around the inner seal in the calliper

must not become damaged as otherwise the

brake calliper will need to be replaced.

Danger !

7.2.3 Clean the seal (X) (see Fig.).

7.2.4 Screw the threaded pipes (16) onto the

brake disc (46) by turning the adapter (61) (screw

out max. 40 mm only) (see Fig.).

7.2.5 Smear the threaded pipes with white

grease (supplied in the repair kit) and then turn

back as far as it will go (see Fig.).

7.2.6 Apply the new inner seal (22) to the thread-

ed pipe (16).

7.1.5 - Unscrewing the threaded pipes (brake

calliper installed)

7.1.6 - Unscrewing the threaded pipes (brake

calliper removed)

7.2.2 - Cleaning the area, levering out the inner

seal

7.2.3 - 7.2.5 - Screw out the threaded pipes and

smear with white grease

Replacing the pressure fittings

29

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND