15

XL-SA20018UM-en-US Rev H · 2017-12-14 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Disc Brake Servicing

Figure 23

HUB SEAL

KEYWAY

AXLE SPINDLE INNER SHOULDER

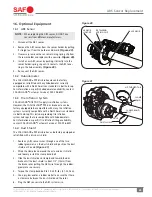

10. Hub Wheel Bolt Servicing

When replacing the wheel bolts, refer to the rotor removal

instructions described in Section 9.

NOTE:

NOT all bolts may need to be replaced. ONLY replace

bolts that are damaged or in need of replacement.

1. Remove the wheel bolts by pressing them out of the head

unit and discard

(Figure 21).

2. Install new wheel bolts by pressing them into the head unit.

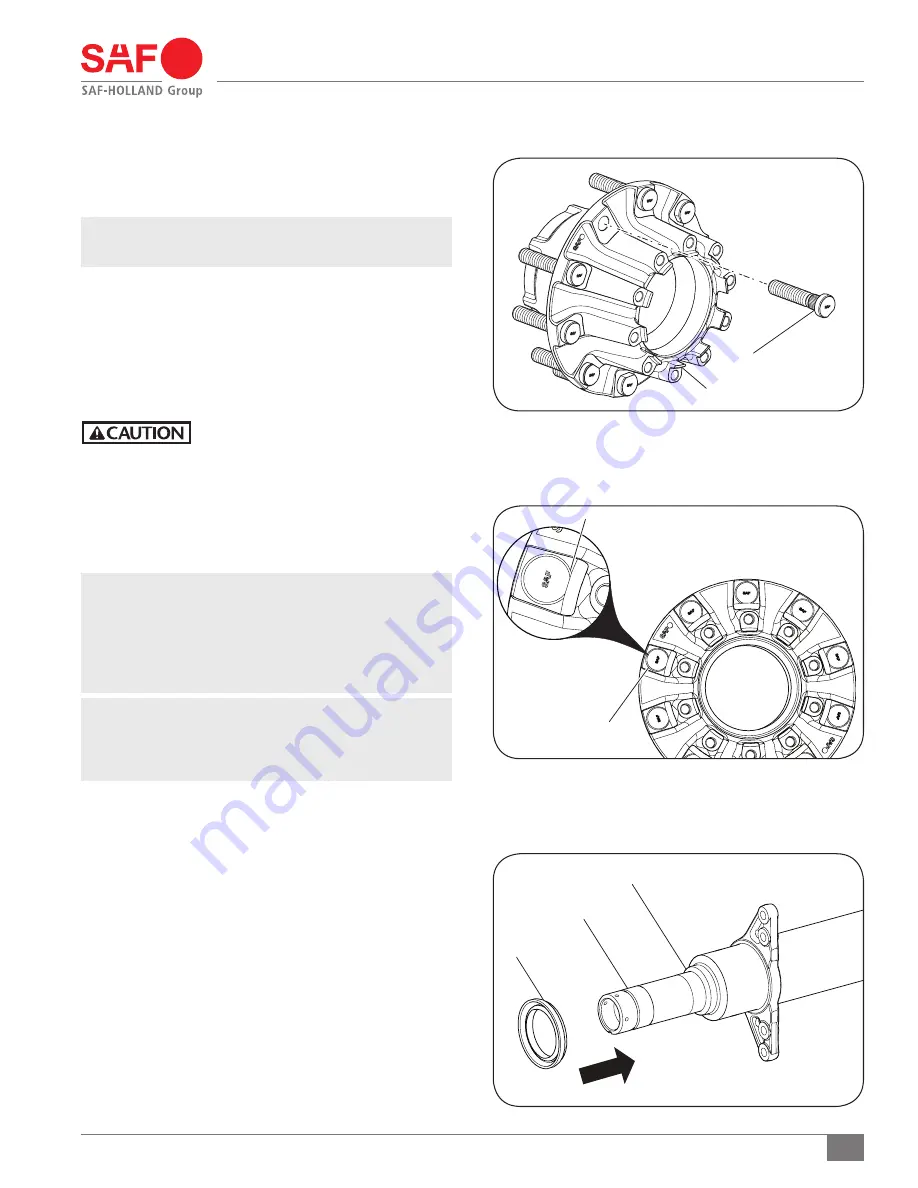

3. For INTEGRAL

®

rotor hub, ensure correct alignment of the

bolts during installation, position the flat side of each

wheel bolt head so that it is facing the center of the hub

(Figure 22)

.

DO NOT hit steel parts with a steel

hammer as parts could break, sending

flying steel fragments in any direction

creating a hazard which, if not avoided,

could result in minor to moderate injury.

11. Seal, Bearing, and Hub Installation

and Adjustment

IMPORTANT:

DO NOT mix oil and grease wheel end

lubricants. All SAF-HOLLAND

®

P89 Disc Brake

wheel ends can be serviced with oil or grease.

Before servicing the SAF-HOLLAND

®

P89 wheel

end with oil, all grease MUST be cleaned with

appropriate solvent from the bearings and hub.

NOTE:

Although all SAF-HOLLAND

®

P89 Disc Brake wheel

ends are manufactured with spindle mounted wheel

seals they can be serviced with either spindle or

hub mounted seals.

11.1 Spindle mounted wheel seal Installation

instructions. (Refer to 11.2 for hub mounted

wheel seal instructions)

1. Before installing the wheel seal on the axle spindle, inspect

the machined spindle seal surface for nicks, scratches, burrs

or marks. If needed, use crocus cloth or emery cloth to

repair any damaged areas.

2. Clean the threads and keyway thoroughly with a wire

brush to avoid false bearing adjustments and to avoid

introduction of contaminants into the lubricant cavity.

Figure 22

WHEEL BOLTS,

TEN (10)

FLAT SIDE OF BOLT HEAD

Figure 21

WHEEL BOLTS (10)

HEAD UNIT