19

XL-SA20018UM-en-US Rev H · 2017-12-14 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Disc Brake Servicing

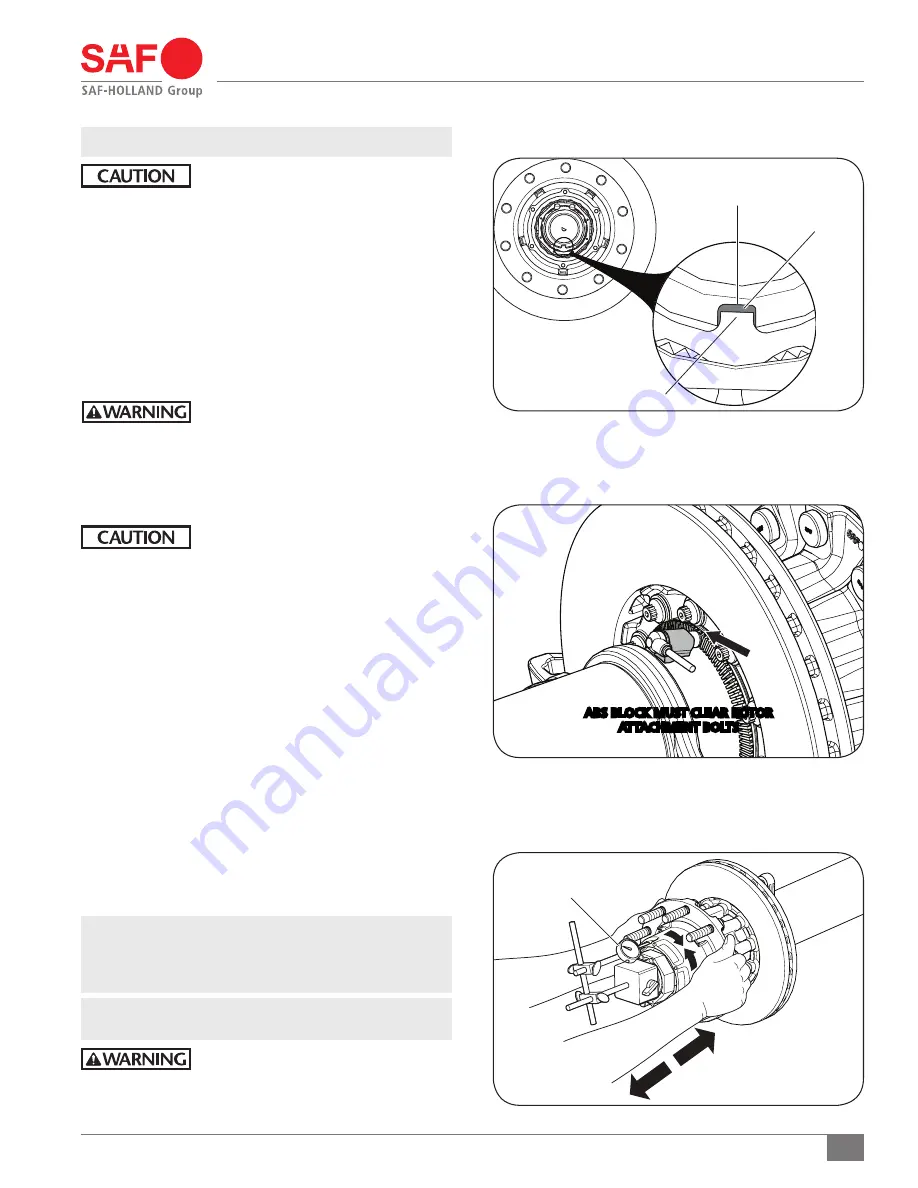

Figure 33

Figure 34

DIAL INDICATOR

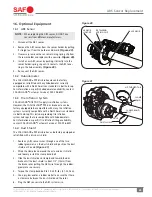

Figure 32

KEYWAY TANG

ABS BLOCK MUST CLEAR ROTOR

ATTACHMENT BOLTS

KEYWAY

NO CONTACT

IMPORTANT:

DO NOT tighten nut to align teeth.

Failure to properly tighten nut could

result in bearing damage which, if not

avoided, could result in bearing failure.

j. Using a dial indicator, verify that end play reading is

.001" (0.03 mm) to .003" (0.08 mm). Re-adjust bearing,

if necessary.

k. Make sure that the keeper tab and keeper

arms are fully seated into the undercut groove.

Inspect the keyway tang to ensure it does not

contact the bottom of the keyway

(Figure 32)

.

If contact exists, immediately notify a Pro-Torq

®

representative.

Failure to ensure that the keeper is

properly installed could cause wheel

separation which, if not avoided, could

result in death or serious injury.

4. ABS sensor block must clear rotor attachment bolts. Refer

to Section 9.

When installing new washers, the

attachment bolts can interfere with the

ABS sensor block. Ensure that there is

clearance provided for ABS Sensor Block

(Figure 33)

. Failure to provide clearance

can cause damage to property. Refer to

service bulletin XL-SA20031SB-en-US for

ABS Sensor Block Modification Procedure.

5. Check the wheel bearing end play as follows:

a. Attach the magnetic base of a dial indicator to the

spindle. Touch dial indicator stem to hub cap gasket

face

(Figure 34)

.

b. Reading Number One - Slightly rotate wheel-end in both

directions while pushing inward until dial indicator does

not change. Set the dial indicator to zero

(Figure 34)

.

c. Reading Number Two - Slightly rotate hub in both

directions while pulling outward until dial indicator

does not change

(Figure 34)

.

d. End play is the difference between reading number

one and reading number two.

NOTE:

Final adjustment should allow the wheel to rotate

freely with 0.001" - 0.003" (0.03 mm - 0.08 mm)

end play. If end play is not within specification,

re-adjustment of bearing is required.

IMPORTANT:

If end play is not within specification,

re-adjustment is required.

Failure to maintain proper hub bearing

adjustment could allow bearing failure and

wheel-end separation which, if not avoided,

could result in death or serious injury.