22

XL-SA20018UM-en-US Rev H · 2017-12-14 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF, and logos are trademarks of

SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Disc Brake Servicing

15. Wheel Installation Procedure

The following information is intended to provide basic wheel

installation instructions. Refer to TMC RP222C for complete

installation details.

1. Clean all mating surfaces on hub, wheels and nuts.

2. Rotate the hub so a pilot boss is at the top

(12 o'clock) position.

3. Mount wheel(s) on hub. One or more of the wheel nuts

can be started in order to hold wheel in position.

4. Tighten the top wheel nut first. Apply 50 ft.-lbs. (68 N•m)

of torque to draw the wheel up fully against the hub.

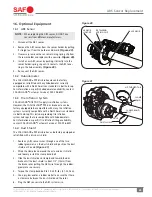

5. Install remaining wheel nuts. Using sequence shown in

(Figure 39)

, tighten all wheel nuts to 50 ft.-lbs.

(68 N•m) of torque.

6. Repeating sequence shown in

(Figure 39)

, retighten all

wheel nuts to 475 ± 25 ft. lbs. ( 644 ± 34 N•m) of torque.

7. Check seating of wheel at the pilot bosses. Rotate wheel

and check for any rotational irregularity.

Re-torque all wheel nuts after 5 to 100 miles of service on the

initial "in-service" following any installation of wheel to hub

assembly.

Figure 39

PILOT BOSS

1

2

10

8

6

3

5

7

9

4