5 Replacement procedure

32

en

XL-SA30000RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND

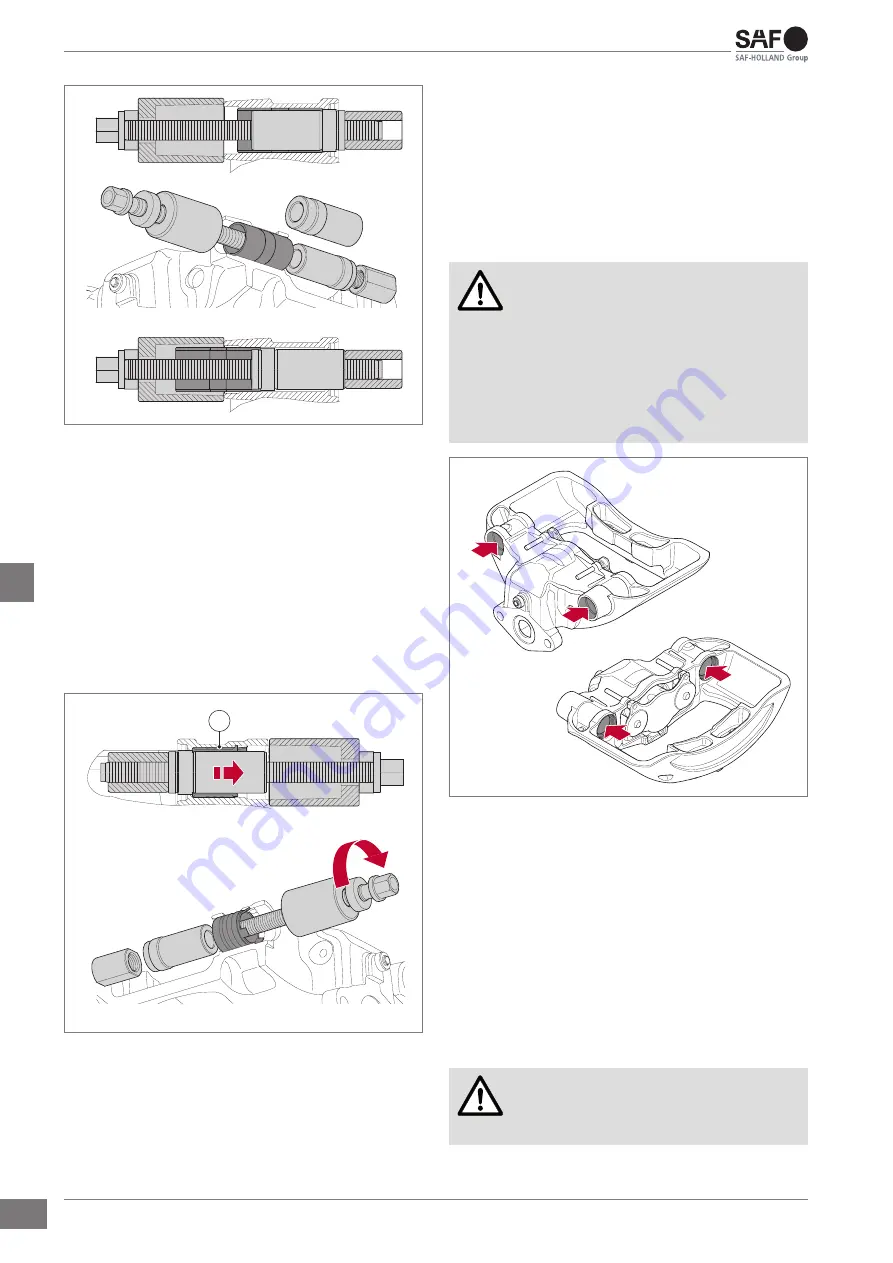

Fig. 62 -

Remove the trailing slide bearing

8.

To remove both bearings (F) and the spacer (G)

on the leading side, assemble in sequence SAF

special tools P/N 4 434 3884 00, P/N 4 434 3837,

P/N 4 434 3848 0, P/N 4 434 3841 0; P/N 4 434

3890 0 and P/N 4 434 3889, as shown in ⇒Fig. 55.

9.

Once fitted correctly, rotate the threaded tool

clockwise, which will pull out the two bearings

(F) and the spacer (G). If necessary, rotate the

mandrel P/N 4 434 3889 00 half way through

the extraction process so that the nut P/N 4 434

3841 00 can be held.

H

Fig. 63 -

Removing the composite bushing

10.

The composite bushing (H) on the floating bearing

should be removed by hand.

11. If this is not possible, assemble in sequence SAF

special tools P/N 4 434 3884 00, P/N 4 434 3837,

P/N 4 434 3848 00, P/N 4 434 3841 00, P/N 4 434

3890 00 and P/N 4 434 3889,

.

12.

Once fitted correctly, rotate the threaded tool

clockwise, which will pull out the composite bush-

ing.

5.5.3 Cleaning

Caution!

●

Use a vacuum cleaner to clean the surfaces. Do

not use compressed-air.

●

Take care when using chemicals and/or cleaning

tools (e.g. knives, brushes, etc.). This to avoid

damage or displacement of hoses, seals and

other components.

Fig. 64 -

Cleaning the brake calliper bearing/bushing mating

surfaces

1. Clean the bearing/bushing/bellows mating sur-

faces of the brake calliper to ensure that they are

free from dirt, moisture, corrosion and damage,

.

2. If the sealing surfaces have lost their protective

surface coating, apply/smear a small amount of

general purpose grease over the whole area so

that when components are refitted, the grease will

provide corrosion protection.

5.5.4 Installing the slide function assembly

Caution!

Where indicated, use an SAF special tool only.