Section 1

Installation Instructions For Post Indicator Valves

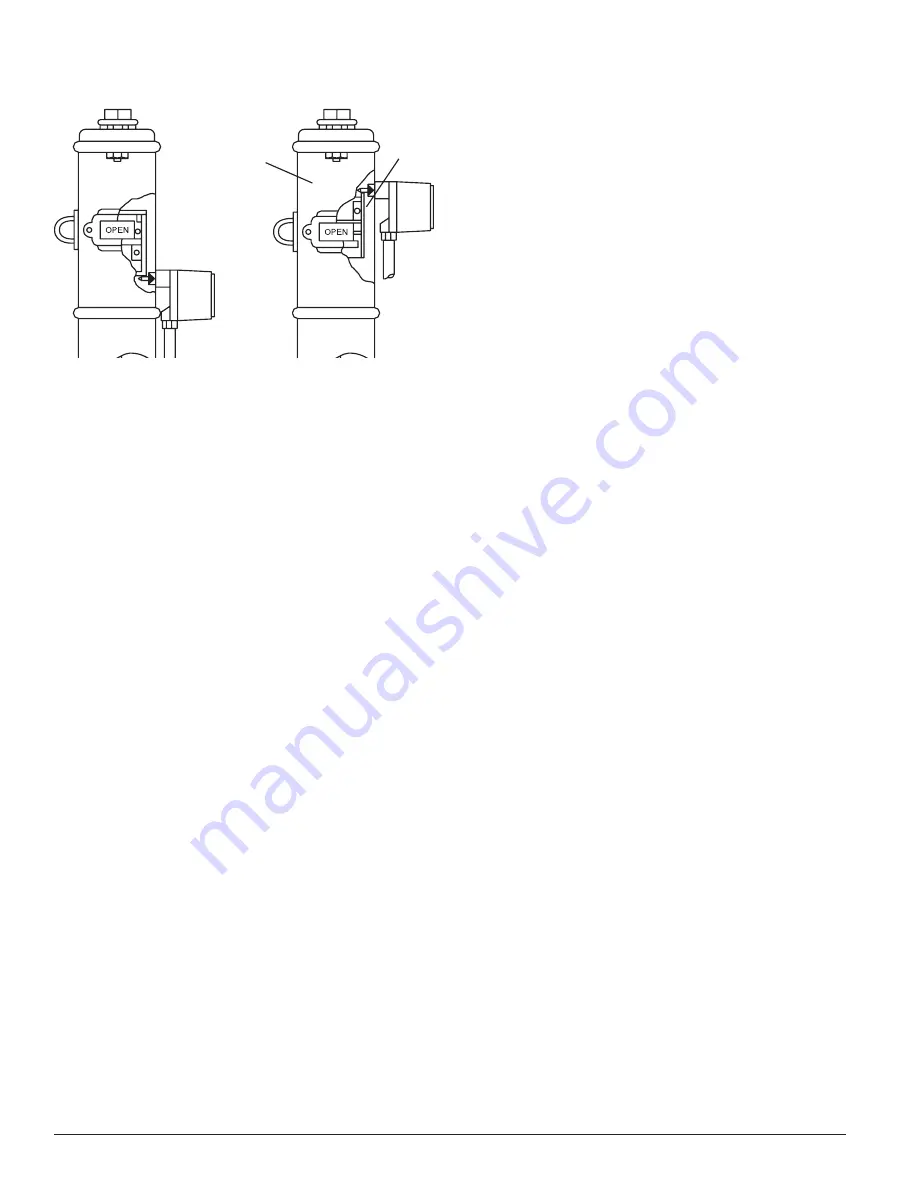

1. There are two types of post indicator valves - rising flag

and falling flag. In a rising flag installation, the PIBV2A

mounts below the target assembly, as shown in Figure 2A.

Closing the valve raises the target assembly and releases the

actuating lever on the PIBV2A. In a falling flag installation,

the PIBV2A mounts above the target assembly (Figure 2B).

Closing the valve lowers the target assembly and releases the

actuating lever on the PIBV2A.

The PIBV2A is set for falling flag installation. If a rising flag

operation is desired, it is necessary to reverse the action of

the switch (See Section 4).

2. If the post indicator valve is predrilled with

1

⁄

2

˝ NPT mount-

ing hole, remove the plug and go to step 6. If the post indi-

cator valve is NOT equipped with a

1

⁄

2

˝ NPT mounting hole,

it will be necessary to drill and tap the hole.

3. Position the valve in the fully open position (“OPEN” should

appear in the window) and remove the head and target

assembly. In doing so, ensure that the assembly can be rein-

stalled with its original adjustment.

4. (a)In a falling flag installation (flag lowers as valve is closed),

measure the distance from the bottom of the head to the

upper surface of the target that will contact the actuating

lever of the PIBV2A. Add

3

⁄

32

˝ to this measurement and

mark the outside of the housing at that location. Drill with

a

23

⁄

32

˝ drill bit and tap a

1

⁄

2

˝ NPT thread.

(b)In a rising flag installation (flag rises as valve is closed),

measure the distance from the bottom of the head to the

lower surface of the target that will contact the actuating

lever. Subtract

3

⁄

32

˝ to this measurement and mark the out-

side of the housing at that location. Drill with a

23

⁄

32

˝ drill

bit and tap a

1

⁄

2

˝ NPT thread.

5. Replace the head and target assembly.

6. Screw the locknut onto the threaded nipple which is sup-

plied with the PIBV2A.

7. Screw the nipple hand tight into the

1

⁄

2

˝ hole in the valve and

Figures 2A and 2B:

HEAD

TARGET

Rising Flag

Falling flag

tighten the locknut against the housing to secure the nipple

in position.

8. Insert a probe into the hole through the nipple to measure

the distance from the open end of the nipple to the desired

position on the target assembly. Subtract

5

⁄

8

˝ from the dis-

tance and set the length of the actuating lever of the PIBV2A

from the end of the enclosure to this distance. Tighten the

screw which holds the actuating lever.

NOTE: Place cover over PIBV2 to ensure that actuating lever

does not interfere with cover. If actuating lever interferes with

cover, remove lever and break off additional length at break-

away point. Repeat step 8 to re-install actuator lever. Refer to

Figure 7.

9. Close the valve 3 to 4 revolutions.

10. Install the PIBV2A onto the nipple and orient the conduit

entry down (See Figure 4). Apply pressure to the PIBV2A

and lock the set screws to secure the nipple to the PIBV2A.

11. Slowly open the valve to its fully open position. The switch

should trip as the valve opens, but not force the actuating

lever against the nipple when fully open. To check for this

condition, open the valve fully and depress the top of the

actuating cam to stretch the actuating spring further. There

should be some additional movement available. If no move-

ment is available, damage may occur to the PIBV2A actua-

tor lever. It will be necessary to adjust the flag location by

removing the head and turning the handle while the valve

stem is disengaged (refer to the valve manufacturer.)

12. After checking the fully open position to ensure adequate

clearance, close the valve slowly until the PIBV2A contacts

trip. The switches must trip within

1

⁄

5

of the full travel dis-

tance of the valve.

13. If the PIBV2A does not change states within

1

⁄

5

of the length

of travel, it may be necessary to adjust the flag up or down by

removing the head and turning the handle (refer to the valve

manufacturer.)

Section 2

Installation Instructions For Butterfly Valves

(See Figure 3)

1. Remove the

1

⁄

2

˝ NPT plug from the gear housing.

2. Loosen 2 set screws that hold the nipple on the PIBV2A and

remove the nipple.

3. Screw the locknut onto the nipple.

4. Screw the nipple into the

1

⁄

2

˝ NPT hole and hand tighten.

Tighten the locknut firmly to the housing to secure the nipple.

5. Open the valve fully and close the valve approximately 3 rev-

olutions, noting which direction the target moves.

6. Retract the actuating arm and install PIBV2A onto the nipple,

orienting the PIBV2A to trip the switch as the valve closes. If

the conduit entry is on the wrong side, it will be necessary to

reverse the action of the switch (see Section 4). Apply pressure

to PIBV2A and tighten set screws to secure the assembly.

7. Slide the actuating arm into the valve until it bottoms on the

flag, but do not tighten the screw which holds the actuating

2

I56-2481-C

4/21