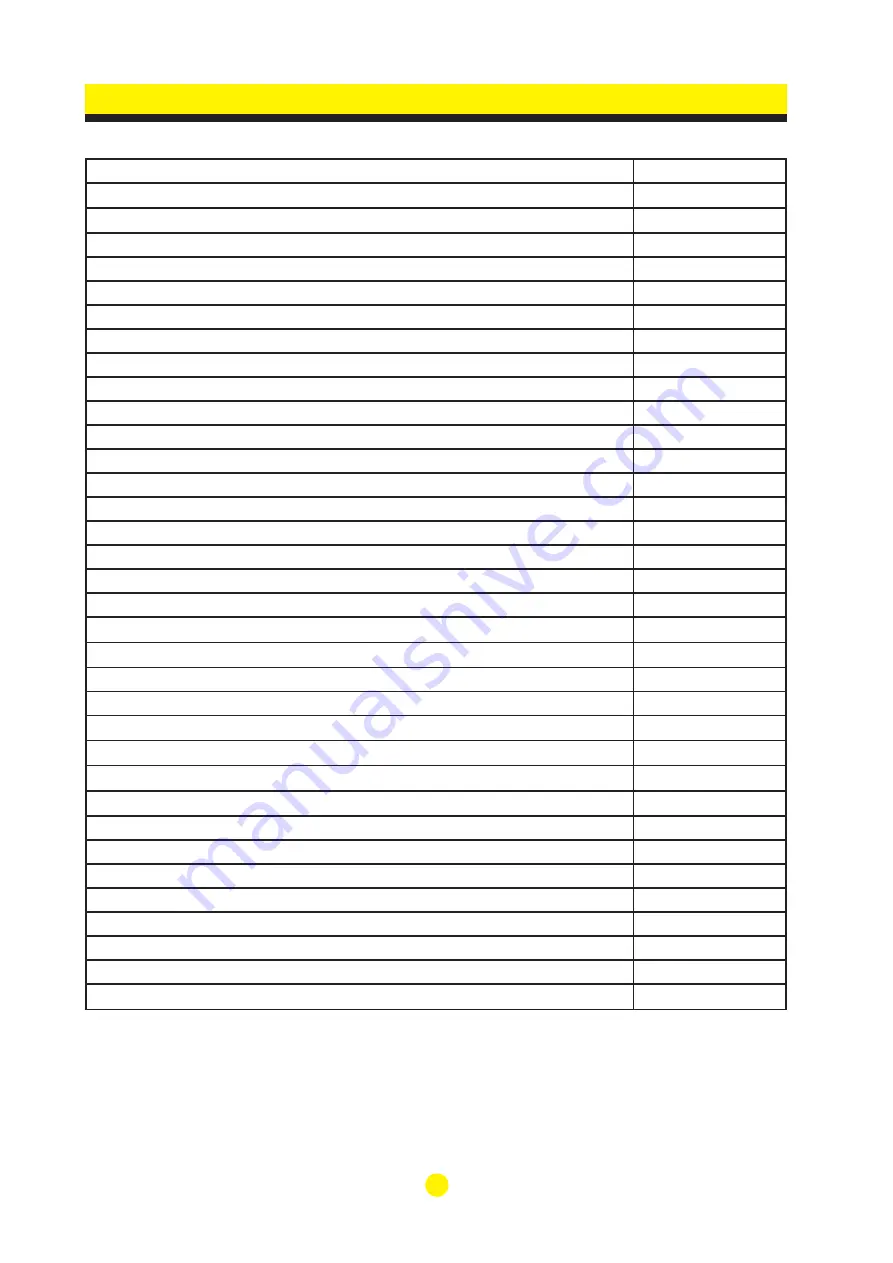

16

Part

Part nummber

S4-Brazing gun

SAFE 9102

S4-Angel brazing gun

SAFE 91035

Pin holder A 8-9,5mm

SAFE 9211

Pin holder B M8

SAFE 9213

Pin holder C M10

SAFE 9215

Pin holder D M12

SAFE 9217

Ring holder 8-9,5mm

SAFE 9202

Ring holder M8/M10/M12

SAFE 9204

Extended Pin/Ring holder set, 8-9,5mm

SAFE 9227

Extended Pin/Ring holder set, M8

SAFE 9229

Gun cable 2,7M

SAFE 9230

Gun cable 4,5M

SAFE 9236

Gun cable extension 5m

SAFE 9235

S4 tool set

SAFE 91250

High Power batteries, sealed 13 Ah

SAFE 8092

High Power batteries, sealed 16 Ah

SAFE 8093

Extra box for 13Ah batteries with lid (excl. batteries)

SAFE 9321

Extra box for 16Ah batteries with lid (excl. batteries)

SAFE 9320

Battery adapter for charging

SAFE 9318

Battery charger, stationary use, 36V 7A

SAFE 8049

Battery charger, car use 12V/36V 2A

SAFE 8055

Battery cables kit

SAFE 93251

Ground Switchable magnet 2,7M

SAFE 80730

Switchable magnet (no cable)

SAFE 9035

Ground super magnet 2,7M

SAFE 8069

Ground grip 2,7

SAFE 8071

Cordless Grinding machine

SAFE 593070

Grinding Pin/Stone

SAFE 8025

Carbide burr, Type C

SAFE 8014

Carbide burr, Type C Extended

SAFE 8014XL

ACCESSORIES AND SPAREPARTS