Safety Clamps, Inc.

VL-BC, VBC Models

4

BEFORE USE INSPECTION

1.

All Safety Clamps should be inspected regularly for signs of

wear and/or damage.

2.

Be sure the clamp to be used is the proper clamp for the job.

Check the rated capacity and jaw opening stenciled on the

clamp. Both should equal or exceed the requirements of the

load to be lifted.

3.

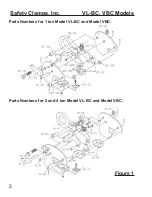

Inspect gripping cams [SC-50 or SC-42, Fig. 1] and

gripping

pad

[SC-70, Fig. 1] for wear and/or damage. Make sure

gripping

surfaces are sharp and clean.

4.

Inspect working parts and joints. Lubricate these regularly

and

make sure they move freely.

5.

Inspect body, jaw opening, and lifting shackle for deformation,

fractures, or any other damage.

6.

For model VL-BC, i

nspect lock spring (SC-61, Fig. 1) for

tension. To do this, lock

the clamp in the closed position and

push on the lifting shackle.

There should be strong resistance

to your pressure on the

lifting shackle.

7.

Make sure that all roll pins are securely in place.

8.

Never use a clamp in need of repair.

9.

If damage is identified or suspected, Safety Clamps, Inc. will

inspect and repair your Safety Clamp for a nominal charge.

Summary of Contents for VL-BC

Page 15: ...Notes ...