MONTHLY INSPECTION

Safety Clamps, Inc. recommends that all of its clamps be

disassembled and thoroughly inspected at least once per month in ac-

cordance with the following procedures:

1.

When disassembling a clamp, clearly label each part so that

the clamp can be properly reassembled. Disassembly

instructions are provided in the “Maintenance and Repair”

section of this manual.

2.

After disassembly, check for body deformation, fractures,

and/

or any other signs of damage in the body and/or parts.

Check

all drilled holes and shackle for roundness. Any

elongation of

holes, shackle, and/or a

stretched jaw opening, is an indication

that the clamp has been overloaded and should not be used.

3.

Check pins and body bolts to ensure they are straight. Make

sure they are not worn and/or damaged.

4.

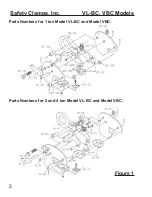

Inspect gripping cams (SC-50 or SC-42, Fig. 1) and gripping

pad (SC-70, Fig. 1). Make sure they are sharp and clean. Do

not attempt to sharpen these yourself. If gripping surfaces are

worn and/or damaged, replace them with genuine Safety

Clamps' parts.

5.

All parts should be cleaned and free of dirt and debris.

WARNING

When replacing parts, use only genuine Safety Clamps' parts.

6.

After reassembling the clamp, ensure all roll pins are securely

in place, then lubricate all joints and make sure the clamp

works freely and properly.

Safety Clamps, Inc.

VL-BC, VBC Models

6

Summary of Contents for VL-BC

Page 15: ...Notes ...