Powered by Safety

®

47

Maintenance

01.4IB.77020

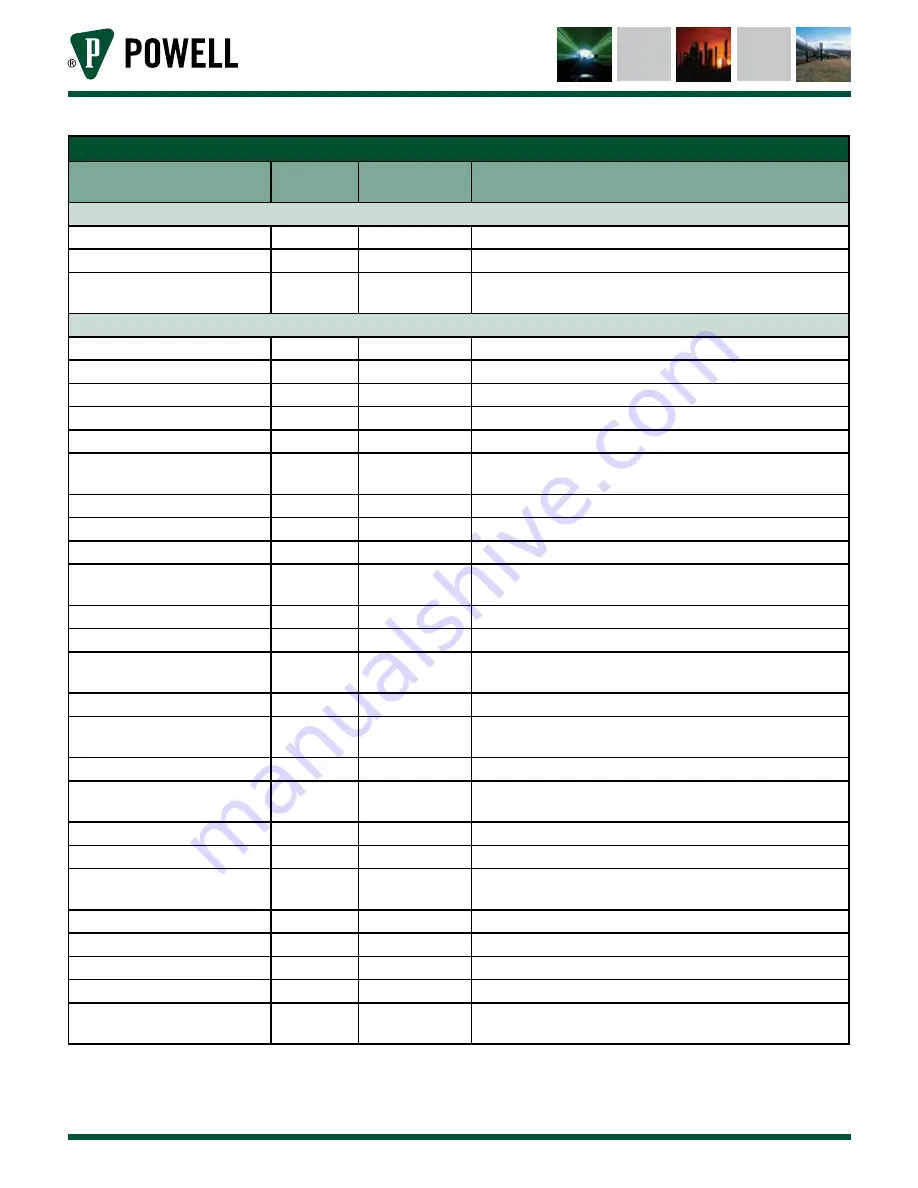

Table B Lubrication

Location

Reference

Figure

Lubricant

Method

Electrical Parts

Primary Disconnecting Device

B - Grease

Wipe clean. Apply lubricant only to actual contact surface.

Ground Connection

B - Grease

Wipe clean. Apply lubricant only to actual contact surface.

Secondary Disconnect

Receptacle

B - Grease

Wipe clean. Apply lubricant only to actual contact surface.

Mechanical Parts

Spring Yoke Pin

C - Oil

Trip Shaft Bearing

C - Oil

Jackshaft Support

C - Oil

Pawl Support Arm

C - Oil

Crank Pin

C - Oil

Motor Drive Shaft Roller Needle

Bearings

C - Oil

Pawls

C - Oil

Close Latch Shaft Face

A - Grease

Apply a light coating of grease and remove all excess.

Ratchet Wheel

A - Grease

Jackshaft Lever Pins passing

through Operating Pushrods

C - Oil

Avoid lubricating on operating pushrods.

Fundamental Linkage Pin

C - Oil

Apply to penetrate where pin passes through end link.

Main Closing Spring Guide Rod

C - Oil

Racking Mechanism

C - Oil

A - Grease

Apply C - Oil to the crank arm rollers and racking crank

arms. Wipe clean. Apply A - Grease to worm gear.

Primary Trip Prop

C - Oil

Open-Close Flag Drive Lever

Pin at Jackshaft

C - Oil

Flag Support Pin

C - Oil

Jackshaft Outer Bearing

Support

C - Oil

Motor Drive Shaft Coupling

C - Oil

Wheel

C - Oil

Motor Drive Shaft Support

Bearings

C - Oil

Camshaft Needle Bearings

C - Oil

Close Shaft Support Bearing

C - Oil

Motor Cutoff Cam

A - Grease

Apply to peripheral surface only.

Fundamental Linkage

C - Oil

Apply to penetrate where pins pass through lines.

Racking Drive Shaft Extension

(PowlVac-ND® Only)

A - Grease

Wipe clean. Extend and apply A- Grease to the exposed

surface.

Note:

For all previous lubrication requirements Powlube-104 A-Grease replaces Anderol 757 and

Rheolube 368A, B-Grease replaces Mobilgrease 28 and C-Oil replaces Mobil 1 and Anderol 456.

See

Ch 5 Maintenance, B. Mechanism Area, 2) Lubrication

for more details.