Powered by Safety

®

50

Maintenance

01.4IB.77020

PowlVac-ND

®

and PowlVac-NDA

™

Series 4

Vacuum Circuit Breakers

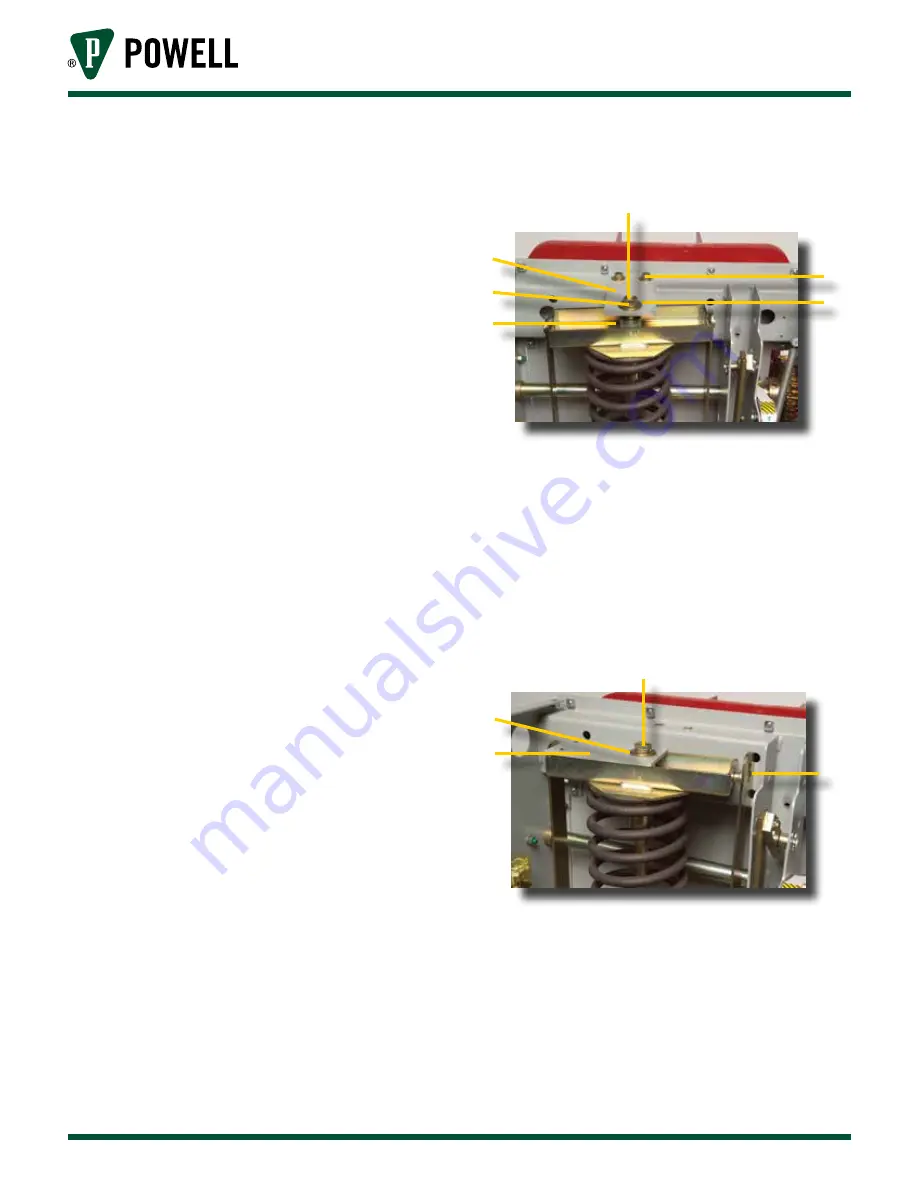

3) Closing Spring Removal

The closing spring must be removed

in order to perform the slow closing of

mechanism.

Although main closing spring removal is

not necessary for lubrication, it may be

necessary for performing adjustments

or major overhaul tasks. Furthermore,

removal of the main closing spring permits

slow closing of the mechanism and the

vacuum interrupter contacts. For details,

Ch 5 Maintenance, B. Mechanism Area,

The procedure for spring removal is as

follows:

1. With the main closing spring discharged

and the circuit breaker contacts open,

remove the bolt at the top of the spring

rod together with the flat washer and

lock washer

2. Remove the horizontal bracket at

the top of the main closing spring by

unfastening the two attachment bolts

.

3. Remove the spacer from above the

bracket.

4. Turn the bracket 90˚, and replace it on

the top of the spring yoke

.

5. Place the spacer below the bracket with

the flat washer below it.

6. Insert bolt and tighten until the tension

is taken off the connecting rods

.

7. With a slight rocking motion of the main

closing spring assembly, the connecting

rods

can now be unhooked

from the spring yoke pins and the

main closing spring assembly can be

removed.

Note:

Care should be taken on reassembly

to ensure correct location of the flat

washer, lock washer and spacer.

Figure 17 Main Closing Spring Assembly

Installed

a. Bolt

b. Bracket

c. Attachment Bolt (2)

d. Lock Washer

e. Flat Washer

f. Spacer

a

b

d

f

e

c

Figure 18 Main Closing Spring Assembly

Compressed for Removal

d

c

b

a

a. Bracket

b. Flat Washer

c. Bolt

d. Connecting Rod