29

Maintenance

Repairs

If repairs on your machine are needed beyond

your capability, call Safety Speed at

800-772-2327. Safety Speed can provide

technical advice or give you the name of a dealer

near you who can service your machine.

WARNING: Always disconnect power

to the machine before doing any

maintenance.

WARNING: Always contact a qualified

electrician for any electrical repairs.

Lubrication

The following areas should be lubricated.

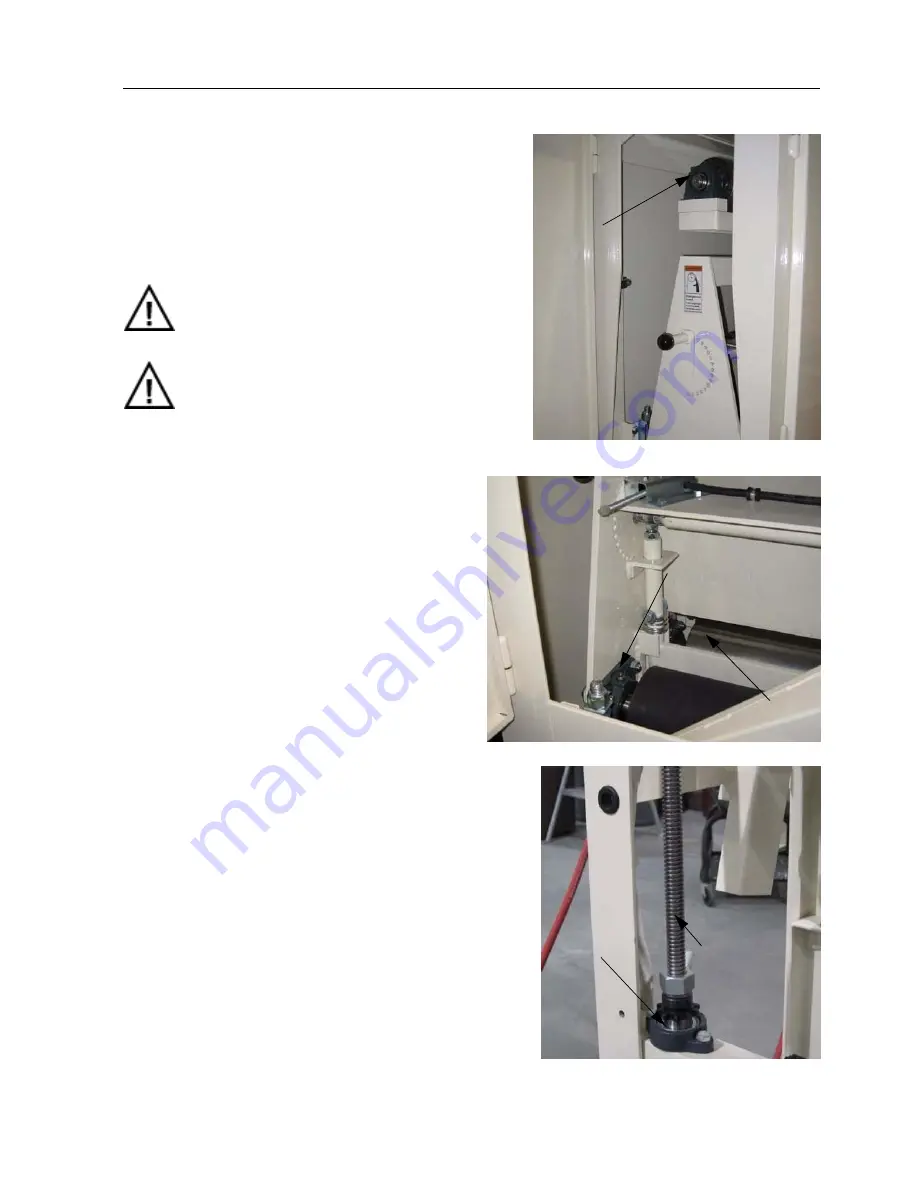

Sanding Head, Contact, and Idler Rollers

The sanding head, contact roller, and idler rollers

are fitted with grease zerts. Grease the rollers

every 20 hours of operation or once a month,

whichever time frame is shorter. See Fig. 54 & 55.

Conveyor Table Rollers

The conveyor table rollers should be greased

every three to four months.

Bronze Bushings

The bronze bushings are located on the jack

screws, hand wheels (not shown) and at the ends

of each of the two pinch rollers (not shown).

Lubricate the bushings with motor oil every 30

days. See Fig. 56.

Jack Screws

The jack screws that support the conveyor belt

should be cleaned with a solvent. The threads

should be lubricated with a lithium based grease

every 30 days or more often in harsher or heavy

use environments. See Fig. 56.

Sanding Head Roller

Grease Zert

Figure 54: Grease Zerts On Sanding Head Roller

Contact Roller Grease

Zert

Rear Idler

Roller

Figure 55: Grease Zerts On Contact Roller

Bronze Bushing

Jack Screw

Figure 56: Jack Screw