LIFT MODEL VISION AS 300 Rev001

8-5

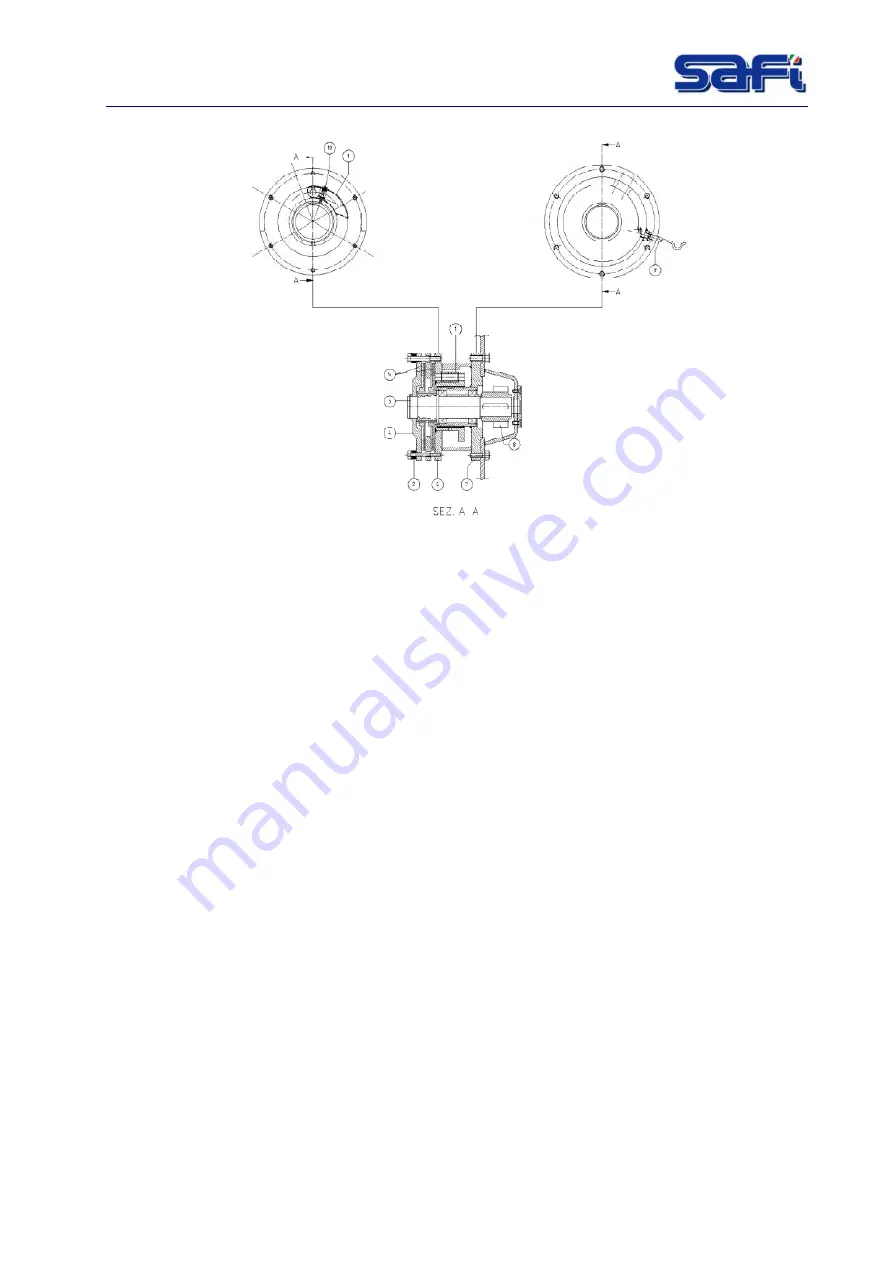

Fig. 8-1 : Parachute brake

Operating

Every motor group is equipped with a parachute which gets tripped downwards when the

machine (very exceptional case) exceeds its nominal speed: this happens only and necessarily

in the event that the motors driving parts are broken. When -during the descent- the nominal

speed is exceeded, the centrifugal mass expands (1). As a result, the support flange holdfast

(7) gets hooked and the mass holding flange (6) together with the closing up flange (4) will stop.

The pads (5), being coupled to the shaft (3) through a groove profile, keep on turning until the

compression between the mass holding flange and the closing up flange, created by the springs

(2), stops the shaft where the pinion (8) which engages the rack is splined. The stop distance is

regulated by the compression of the Belleville washers (2). The strength which contrasts the

expansion at the nominal speed of the counter-weight is generated by a spring (10) adjustable

by means of a screw.

ATTENTION:

The annual test is compulsory in order to test the efficiency of the

parachute brake and it must be required by the user to the

manufacturer or to the mandatory!

ATTENTION:

Grease the parachute brake every 3-4 months!

Summary of Contents for VISION AS 300

Page 2: ......

Page 4: ......

Page 43: ...LIFT MODEL VISION AS 300 Rev001 7 4 Fig 7 1 Dimension...

Page 68: ...LIFT MODEL VISION AS 300 Rev001 12 1 12 WIRING DIAGRAMS Fig 12 1 Wiring diagram Power supply...

Page 69: ...LIFT MODEL VISION AS 300 Rev001 12 1 Fig 12 2 Wiring diagram Motor power supply...

Page 70: ...LIFT MODEL VISION AS 300 Rev001 12 2 Fig 12 3 Wiring diagram Emergency circuit...

Page 71: ...LIFT MODEL VISION AS 300 Rev001 12 3 Fig 12 4 Wiring diagram Auxiliary...

Page 72: ...LIFT MODEL VISION AS 300 Rev001 12 4 Fig 12 5 4 Wiring diagram Auxiliary PLC logo expans...

Page 73: ...LIFT MODEL VISION AS 300 Rev001 12 5 Fig 12 6 Auxiliary circuit...

Page 74: ...LIFT MODEL VISION AS 300 Rev001 12 6 Fig 12 7 Wiring diagram Connectors C1 C2 C3...

Page 75: ...LIFT MODEL VISION AS 300 Rev001 12 7 Fig 12 8 Wiring diagram Terminal box electric panel...

Page 76: ...LIFT MODEL VISION AS 300 Rev001 12 8 Fig 12 9 Wiring diagram Cable call floor...

Page 77: ...LIFT MODEL VISION AS 300 Rev001 12 9 Fig 12 10 Wiring diagram Floors call connection...

Page 78: ...LIFT MODEL VISION AS 300 Rev001 12 10 Fig 12 11 Wiring diagram Box floor call connection...

Page 79: ...LIFT MODEL VISION AS 300 Rev001 12 11 Fig 12 12 Wiring diagram Box Fencing connection...

Page 80: ...LIFT MODEL VISION AS 300 Rev001 12 12 Fig 12 13 Wiring diagram Cable fancing call...

Page 81: ...LIFT MODEL VISION AS 300 Rev001 12 13 Fig 12 14 Main electrical box components...

Page 82: ...LIFT MODEL VISION AS 300 Rev001 12 14 Fig 12 15 Material list 1...

Page 83: ...LIFT MODEL VISION AS 300 Rev001 12 15 Fig 12 16 Material list 2...