SAFIRE 2400Di, 2600Di, 3200Di and 3600Di Diesel / fuel oil heaters

7

USAGE, INSTALLATION AND MAINTENANCE

January 2011

SF- Lämmitin Oy

Tilhenkatu 1 20610 Turku Finland Puh/Fax +358(0)2-2443282

EXAMINATION, MAINTENANCE AND SERVICE

EXAMINATION

Check regularly especially, if the combustion in the

burner is different, that

1. the heater gets current.

2. the combustion air access is clear; f. ex.

spiders, mosquitoes, snow, water or ice

can block the air flow.

3. the exhaust outlet is clear.

4. the fuel hose does not leak.

5. there aren’t any impurities or water on the

bottom of the fuel tank.

6. the fuel filter is clean.

7. the air hose of the tank is clear.

8. there isn’t any dust inside the heater; it

may cause smells and risk of fire.

If the heater doesn’t seem to get enough fuel (the

power is lower, the combustion is different),

measure the fuel inlet: Remove the fuel filter (it

may cause measurement errors). When the

heater operates normally on maximum power, put

the fuel hose into a measuring glass with a certain

amount of fuel in it. Let the heater operate for 6

minutes. Multiply the amount of fuel consumed by

10, and you will get the fuel inlet/hour.

On maximum power the

3600D

i heater consumes

340-380ml/h,

3200Di

heater 300–340 ml/h,

2600Di

, heater 240-280ml/h and the

2400Di

heater 220–260 ml/h.

If the measured fuel consumption is above these

limits, check the cause: the tank (or the measuring

glass) may be placed above the heater, or the

default settings of the pump have been changed

and the pumps pulsation is too frequent. The

normal pulsation on maximum power with the

3600Di

heater is180 pulses/min and 50 pulses/min

on minimum power

3200Di

heater is 160

pulses/min and 50 pulses/min on minimum power

2600D

i heater is 130 pulses/min and 50

pulses/min on minimum power, with the

2400Di

heater 120 pulses/min on maximum power and 50

pulses/min on minimum power.

If the heater gets too much fuel, the combustion

may be impure and cause risk of overheating. If

the overheating is caused by defective electronics

or pump, always contact your nearest

maintenance service.

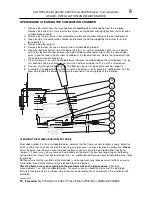

If the fuel consumption is too low, there might be a

blockage in the fuel system. If the filter is clean,

check the fuel hose: the fuel in it may be clouded,

if the hose has been in a cold place for a long

time. If the blockage is not thorough, you can

dissolve it rather quickly with isopropanol

(= common anti-freeze for gasoline engines).

You may also force isopropanol into the hose

when the pump operates (during start) f. ex. with

a hypodermic syringe or bicycle pump.

Also a little leak in the suction hose (before the

pump) may cause the low fuel consumption.

Check if there is a significant amount of bubbles in

the hose. With extensive usage also the fuel inlet

pipe near the burner may be blocked. If this

happens, change the pipe or clean it f. ex. by

heating it with a gas flame and blowing by

compressed air it empty.

WINTER

Remove the battery wire for winter.

If the heater is unused in a cold place for a long

time, the fuel in the hoses and in the tank may

become clouded (this may happen also with winter

grade fuel oil). The last time you use the heater

before the winter, use paraffin oil to avoid starting

problems in the spring. Make sure that paraffin oil

fills the fuel hose, the pump and the fuel filter. In

the spring it’s best to acquire new fuel.