SAFIRE 2400Di, 2600Di, 3200Di and 3600Di Diesel / fuel oil heaters

8

USAGE, INSTALLATION AND MAINTENANCE

January 2012

SF_ Lämmitin Oy

Tilhenkatu 1 20610 Turku Finland Puh/Fax +358(0)2-2443282

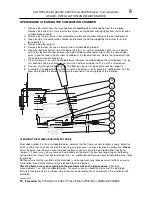

OPENING AND CLEANING THE COMBUSTION CHAMBER

1. Remove the heater from the mounting bracket;

watch out

for fuel dripping from the fuel pipe.

Remove the bottom first: Unscrew the two screws on the bottom and tap lightly from the ends with a

suitable block of wood.

2. Remove the thermal barrier from around the combustion chamber. Remove the fuel feed pipe (2).

3. Open the lid of the combustion chamber and remove the spring supporting the burner (3) and its

base plate (11).

4. Remove the glow plug (1).

5. Remove the burner (8): use a hammer and a suitable block of wood.

6. Open the lock mechanism (4) of the burner cap (5) f. ex. with a screwdriver: push the screwdriver

next to the lock mechanism between the hole cylinder and the lower ring so that the hole cylinder

gives in and the lower ring has room to slide pass the lock mechanism. Rotate the screwdriver and

lift the burner cap simultaneously.

7. Clean the burner f. ex. with an old toothbrush. Remove the carbon deposit from the bottom f. ex. by

first heating it with a gas flame or warm air fan and then scraping it off f. ex. with a screwdriver.

8. If necessary, change the backing (6). The backing stays on its place with a locking spring (7).

9.

Assemble in an opposite order. Make sure that the burner is on its place in a right position. Use the

glow plug to align the burner. Check also the position of the casing pipe of the fuel pipe.

CLEANING THE FLAME SENSOR ELECTRODE

Error code number 2 in the circuit board display indicates that the flame sensor electrode is sooty, defective

or that a short circuit has occurred on the housing. A sooty sensor is caused by impure combustion;

always

clean the burner too. After you have removed the burner, you can clean the electrode without having to

remove it. If necessary, you can remove the electrode on the end of the heat exchanger: open the locking

spring under the “claws” that keep it steady. Use f. ex. alcohol-based cleaning agent (windshield washer fluid)

for cleaning.

NB! Make sure that the insulation of the electrode is clean to prevent any leakage current which can cause

malfunction. Don’t let the filament of the electrode touch the burner!

Place the flame sensor tip according to the measurements on the picture above.

Check the

measurements f. ex. with a cardboard model. If necessary, you can bend the filament of the electrode.

Be careful not to break the insulation. Small fractures however don’t have an impact on the function of the

electrode.

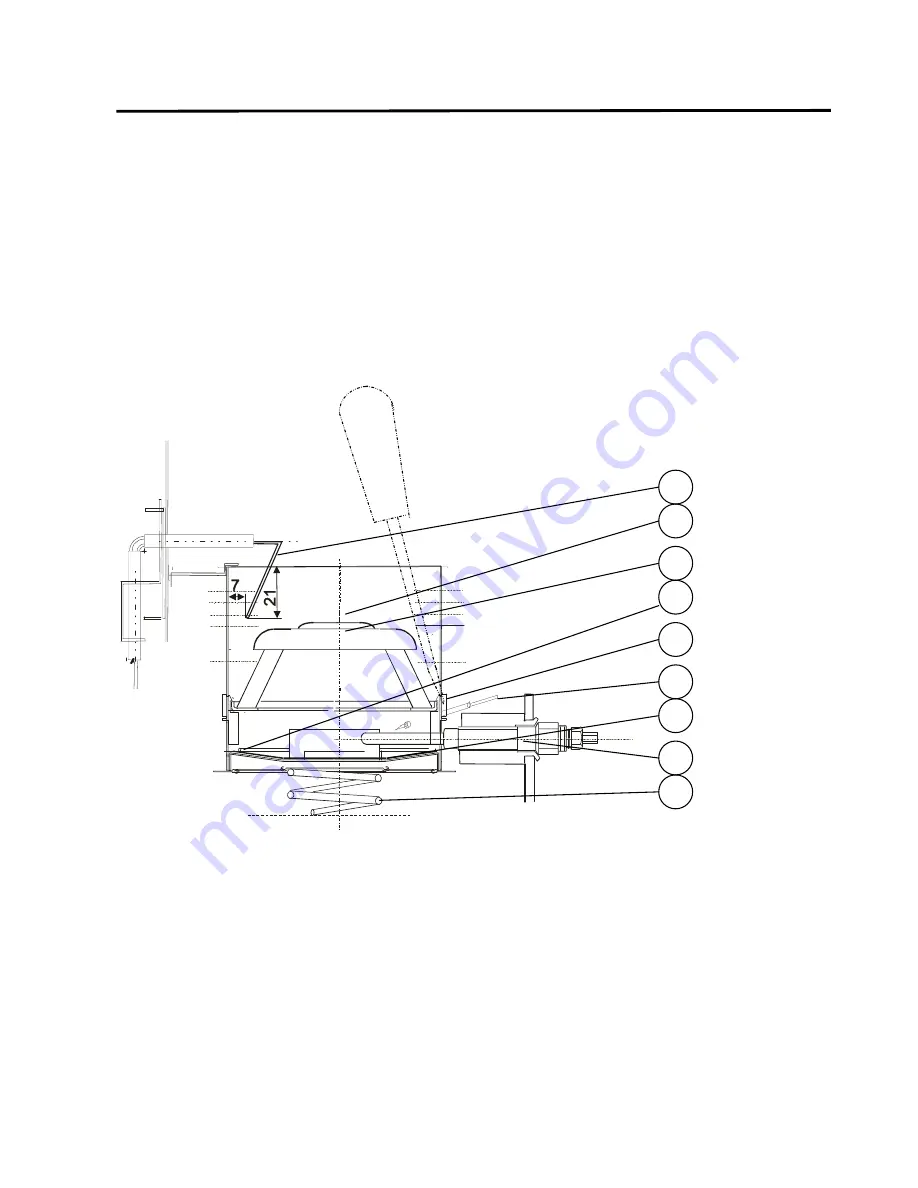

10

8

5

7

4

2

6

1

3