M5 x 10

M5

1

M5

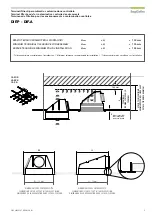

DIF.P - DIF.A

SIEF_20200507_DIF.P-DIF.A _M

6

Terminali filtranti per ambienti a contaminazione controllata

A

•

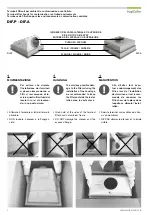

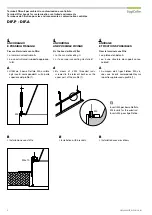

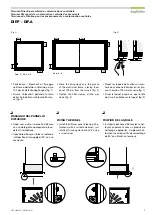

Utilizzare 4 barre filettate M5, avvitate

agli inserti corrispondenti sulla parte

superiore del profilo (1).

B

•

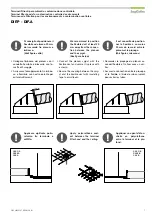

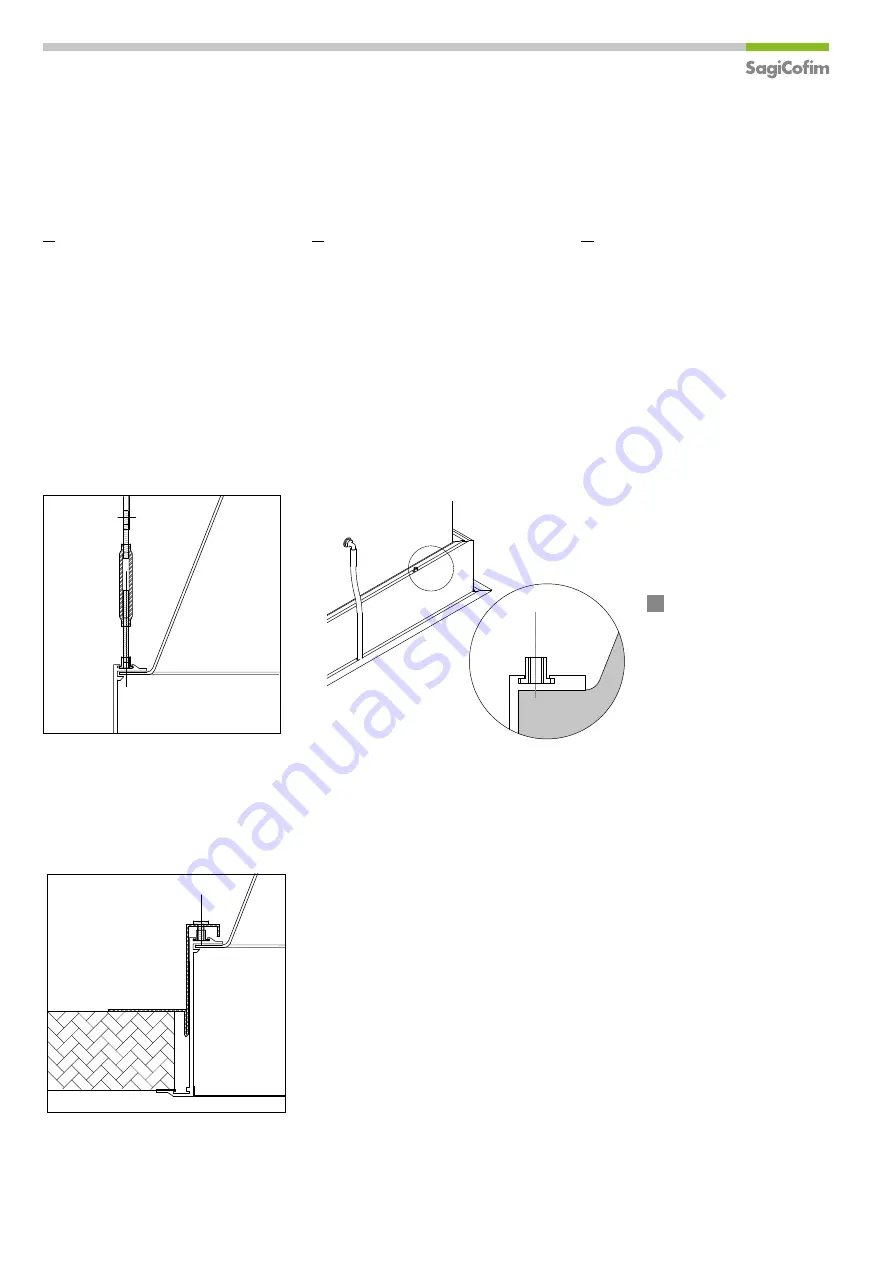

Installazione con staffe

4

ANCORAGGIO

E POSSIBILI FISSAGGI

Fissare il terminale senza filtro

•

al solaio in calcestruzzo

A

•

o a una struttura di supporto appropria-

ta

B

Inserti M5 per barra filettata

M5 inserts for threaded rod

Inserts M5 pour tige filetée

Terminal filter hoods for contamination controlled environments

A

•

By means of 4 M5 threaded rods,

screwed to the relevant bushes on the

upper part of the profile (1).

B

•

Installation with brackets

4

ANCHORING

AND POSSIBLE FIXINGS

Fix the hood without filter

•

to the concrete ceiling A

•

or to a proper supporting stucture B

Terminaux de filtration pour les environnements à contamination contrôlée

A

•

Au moyen de 4 tiges filetées M5, vis-

sées aux inserts correspondantes sur

la partie supérieure du profilé (1).

B

•

Installation avec des étriers

4

ANCRAGE

ET FIXATIONS POSSIBLES

Fixer le terminal sans filtre

•

au plafond en béton A

•

ou à une structure de support conve-

nable B