SE_20200507_HTE400_M

11

HT400 Rectangular fi re damper - UNI EN 1366-2 Certifi ed - UNI EN 13501-3 Classifi ed

MATERIAL

1. Bushing

Nickel-plated brass CW 614N

2. Spring

Inox 303 / S.S. 303

3. O-Ring 4087

Viton 75 SH

4. O-Ring 3125

Viton 75 SH

5. 1/

4

” BSP flare x 1/

8

NPT nipple

Nickel-plated brass CW 614N

6. O-Ring 112

Viton 75 SH

7. Pin

Nickel-plated brass CW 614N

8. Bushing

Z 140 galvanised nickel-plated brass

CW 614N

TECHNICAL DATA

Intervention pressure

3 bar

Max pressure work

250 bar

Minimal pressure of pneumatic testing

2,5 bar

Max pressure of pneumatic testing

300 bar

Desing temperature x CO

2

, N2

-20 +200 °C

Desing temperature for vapor

-40 +140 °C

Weight

0,558 Kg

For vapor supply, EPDM O-ring are used

69

90°

6

5

8

7

4

3

2

1

Ø10

Ø4.5

100

91

89

20

22

17

13

51

8

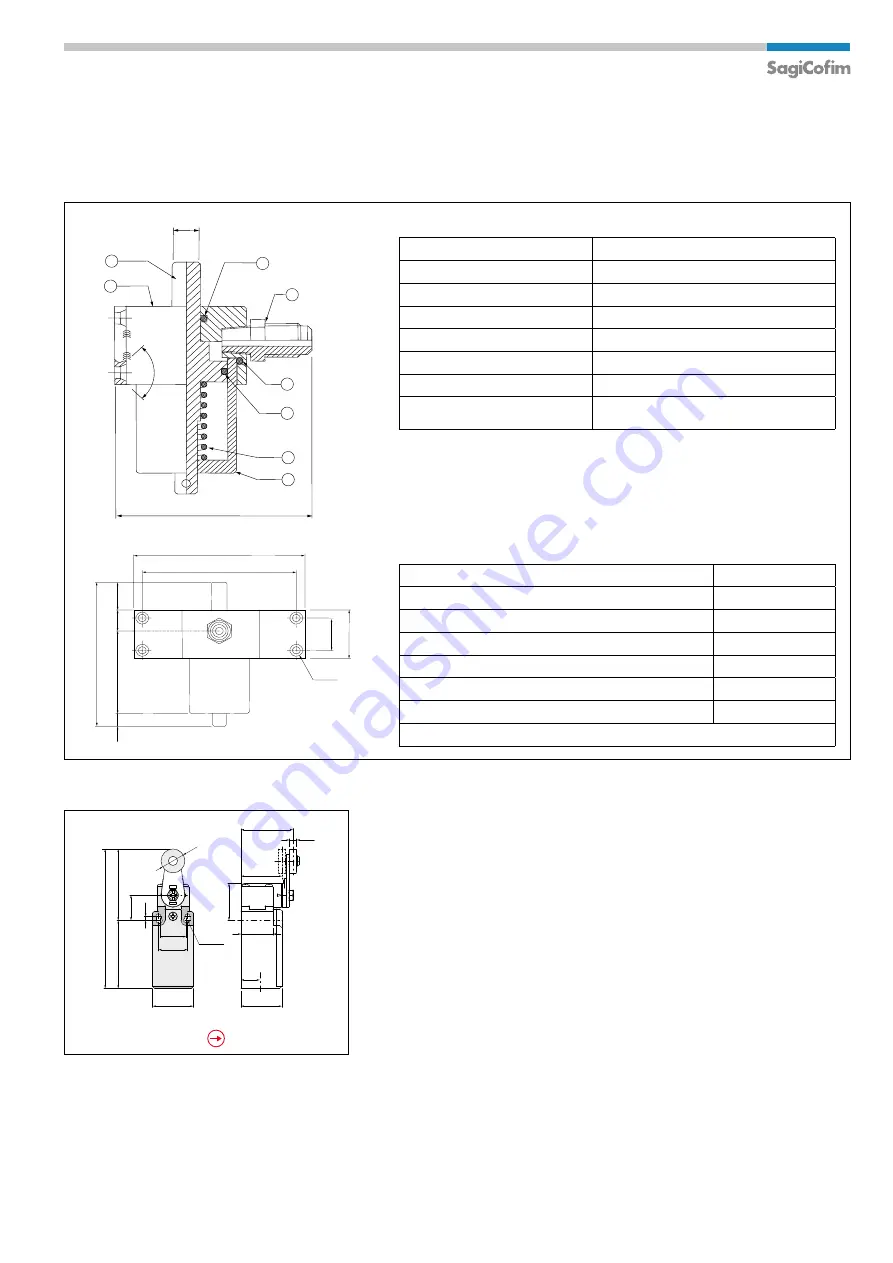

CO

2

RELEASE Mod. LNMTOTT33NICH

SIGNAL MICROSWITCH

18

20

22

54

51.5

105.5

19

3

30.8

4.2x7.2

14.2

28

39.4

31.1

5.4

30.8

24.2

FD531

1NO + 1NC

1.5

HTE 400 + CO

2

DRIVEN RELEASE- Confi guration G0

CO

2

release - Signal microswitch