ENGLISH

26/27

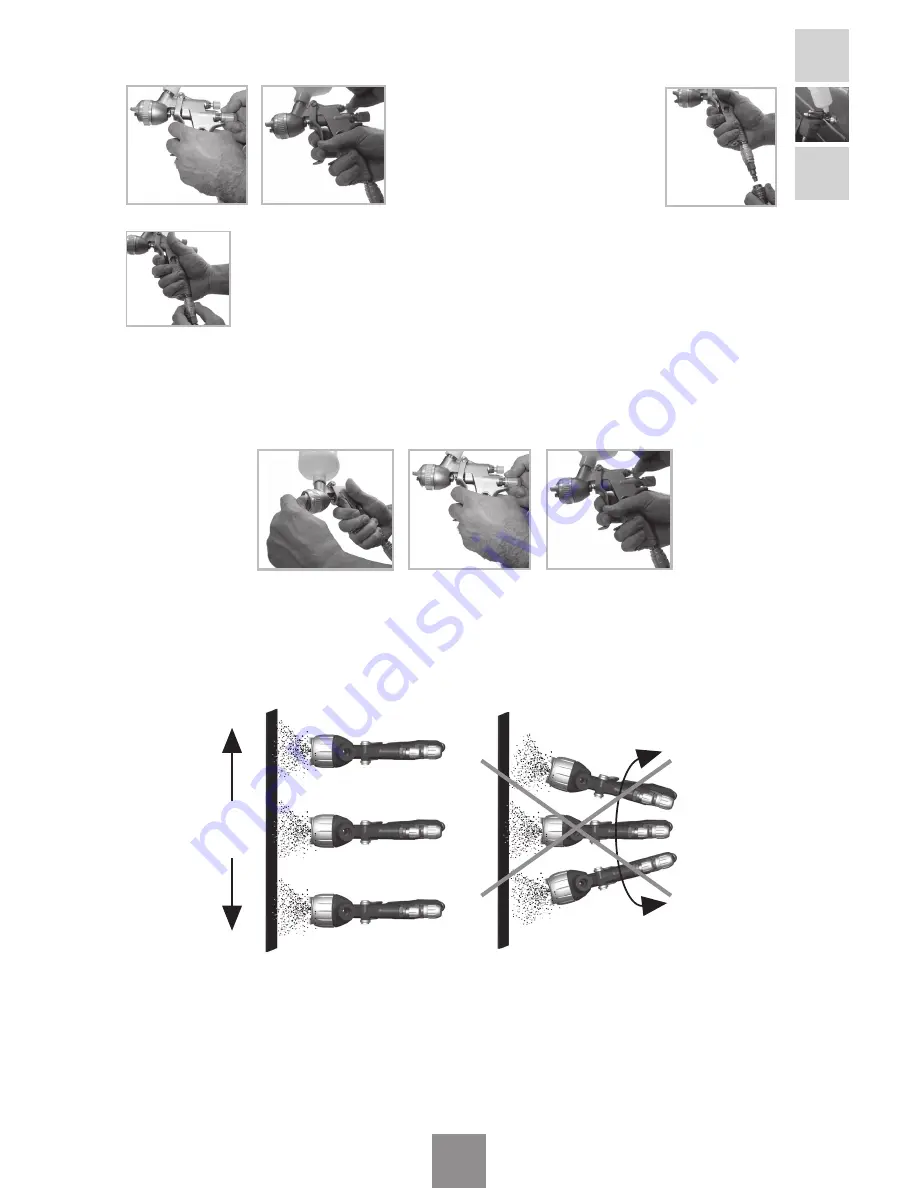

Connect the gun to the compressed

air network.

Adjust the air pressure in the network

regulator

in order to compensate for

any pressure drop in the network

(estimated at 0.6 bar for each 10 m

of hose).

Adjust the air pressure in the air nozzle by operating the flow regulator

until the

required quality of finish is obtained (better finishes are not obtained with

higher spraying pressures and these lead to lower performance and worse

product transfer).

Position the air nozzle spraying orifices appropriately

(when an imaginary line is drawn through

the 2 lugs, this must be parallel or perpendicular to the floor) and perform the required application

test by adjusting the product and spray width regulators as follows:

Close the product regulator

until the appropriate amount of product comes out. Now you have

the maximum spraying width (spraying pattern). You can reduce this according to your needs

by closing the spray width regulator.

Please be sure that you

put the spray gun properly

by keeping its perpendicularity to the piece

to be painted in order to achieve the maximum transfer of the sprayed product and obtain the

best finishing quality.

11.1.- Clean Air

The air used for spraying must reach the gun free of impurities, aerosols, oil, silicone and solid

particles. To do this you must eliminate these with coalescent filter units.

The use of air treatment equipment with built-in pressure regulators is recommended (Models

SAGOLA 5200, 5300 or 5300 Plus.

OK

Summary of Contents for 4500xtreme

Page 2: ......

Page 3: ......

Page 4: ......

Page 14: ...ESPA OL...

Page 30: ...ENGLISH...

Page 46: ...PORTUGU S...

Page 54: ......

Page 55: ......