- 20 -

14. MAINTENANCE

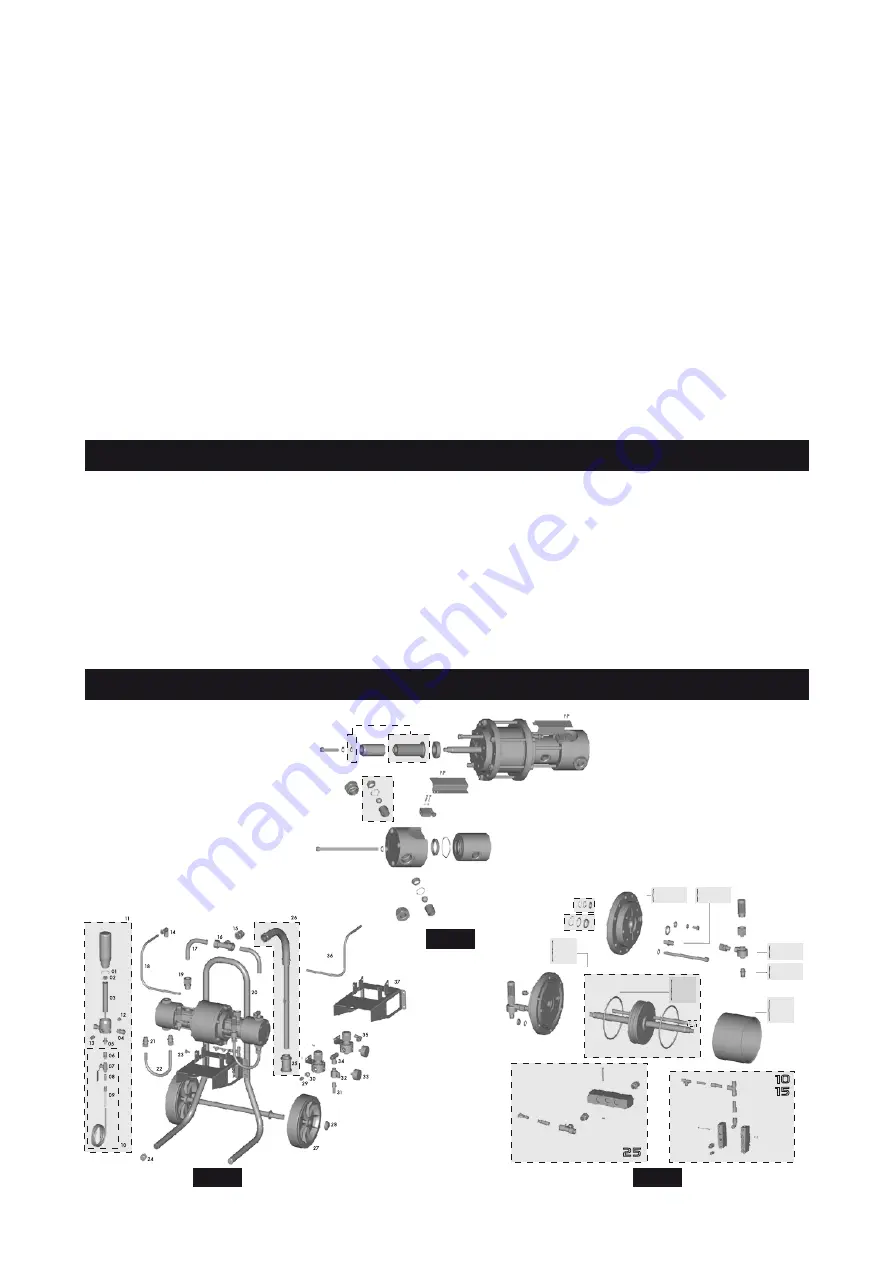

15. PARTS LIST

page 9

page 10

page 11

It is considered that the unit and its accessories are

totally clean when the product sprayed through the

gun, and that circulating through the product return

probe (Fig.1 nº2), is clean thinner and free from the

product previously applied, meaning that the process

must be repeated as many times as necessary.

Once the unit and its accessories are clean, and as a

prior step before definitively stopping it, the Depressu-

risation procedure described before in Section 10 of

the Manual must be applied.

Clean the Suction Probe filters or the product cup, antipul-

se and those of the spray gun.

Remove any remains of product from the gun, hoses and

the rest of the unit with a cloth soaked in thinner.

Keep gasket areas free of accretions and foreign bodies.

The air cap is a precision component. Any deformation,

especially in the product outlet orifices, may cause

malfunctions in its operation and incorrect or deficient

quality spraying.

If necessary, dip the air cap in thinner in order to soften the

remains of product or dirt. Once softened, blow the cap

with compressed air until any remains of product and

thinner are eliminated.

For automatic cleaning of the gun, tools and accessories

used in the mixing and preparation of the product to be

applied, we recommend the use of SAGOLA Washing

Machines.

IMPORTANT

The gun can be cleaned with thinners or detergents in

a gun washing machine.

If you opt for this cleaning system, we advise you to

remember the following considerations, which, if not

applied, may damage the gun and render the warranty null

and void.

1- Do not submerge the gun in solvent or detergents longer

than the time required for cleaning.

2- Do not use the gun immediately after cleaning has been

completed.

3- Ensure that there is no thinner or detergent inside and

that it is completely free of these. Other cleaning systems

can be used (ultrasound).

Before starting to work, verify the state of the product

hoses and the connections of the elements through which

the product flows.

In order to carry out maintenance or repairs, first discon-

nect the unit from the compressed air distribution network.

Never move the unit by tugging on the hoses.

Always place the unit at a distance of least 6 metres away

from where the product is to be applied.

Do not apply excessive force or inadequate tools for main-

taining and cleaning the unit. Some repairs must be done

with special tools on some occasions. In these cases, you

must contact the Customer Service of SAGOLA. Any hand-

ling of this product by non-authorised personnel would

render the warranty null and void.

The unit must be overhauled on a periodic basis to check

the status of its components and replace these when they

are not in perfect condition.

IN ORDER TO OBTAIN THE BEST POSSIBLE

RESULTS, ALWAYS USE ORIGINAL SAGOLA SPARES

THAT GUARANTEE TOTAL INTERCHANGEABILITY,

SAFETY AND PERFECT OPERATION.

38

39

40

41

42

43

53

44

45

46

47

48

49

52

50

51

54

39

56 57

58

73

74

75

76

78

79

HT

HT

HT

76

77

80

81

82

83

72

82

85 86

88

89

90

91

87

84

1 HT10

2 HT15

3 HT25

1 HT10

2 HT15

3 HT25

1 HT10

2 HT15

3 HT25

95

1 HT10/15

2 HT25

94

06

63

39

69

71

92 39

70

68

64

65 66

67

61

59

60

1 HT10/15

2 HT25

1 HT10/15

2 HT25

1 HT10/15

2 HT25

93

92

Summary of Contents for HT10

Page 2: ......

Page 9: ... 9 15 DESPIECE ...

Page 10: ... 10 15 DESPIECE 38 39 40 41 42 43 53 44 45 46 47 48 49 52 50 51 54 39 56 57 58 ...

Page 24: ......