33 |

Sailrite�com

Leatherwork

®

Guidebook

| 34

Thread Issues

Thread is shredding,

balling or breaking

There are a number of causes for

breaking thread� Start with step 1 and

stop as soon as the problem is resolved�

1� Thread/needle combination too small for

material being sewn� See p� 6�

2� Make sure thread is not snagging

anywhere from the cone/spool to the

needle�

3� Wrong Needle Type

Use of the wrong needle type can

contribute to thread shredding issues�

Always use a leather “diamond point”

needle when sewing dry, heavy or hard

leather�

Refer to p� 7 for more information�

4� Incompatible Needle Size & Thread

Weight

If the thread is too thick or thin for the needle it

will not pass through the needle eye to form a

loop and will instead ball at the needle� Check

the compatibility of the needle size and thread

weight (p� 6)�

39

5� Replace the needle, making sure installation is correct� See p� 8�

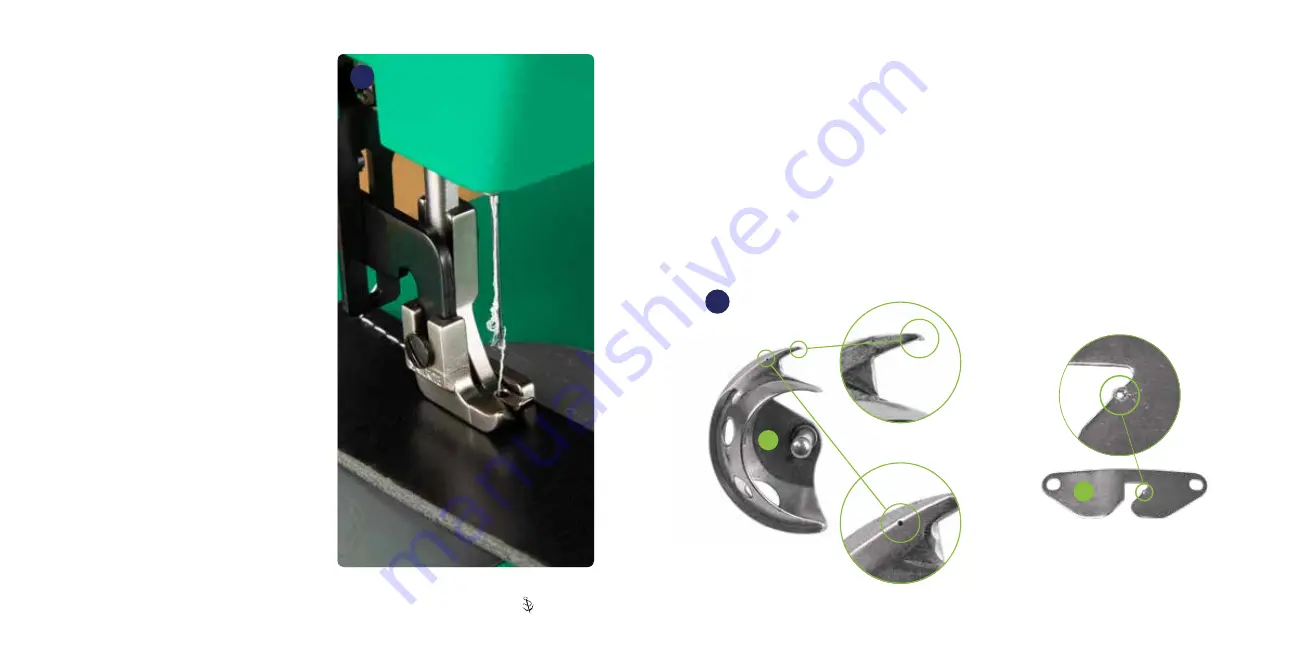

6� Burred Shuttle Gib Hook or Retaining Ring Cap Spring

A machine crash or needle strike to the Shuttle Gib Hook (

A

) or Retaining Ring Cap Spring (

B

) may

result in a burr or damage which can cause the thread to snag�

Remove any burrs by polishing them with emery paper or a fine file. If badly damaged, replace

with a new Retaining Ring Cap Spring (#1603) and/or new Shuttle Gib Hook (#9601)�

7� Machine Has Gone Out of Timing

If the machine is out of timing it may cause the gib hook point to cut or shred the thread� To reset the

timing on your Leatherwork, follow the steps outlined on p� 39 “Leatherwork Timing�”

Burred/

Damaged

Area

Burred/Damaged Area

>

Retaining Ring Cap Spring

>

Shuttle Gib Hook

40

B

A

Summary of Contents for Leatherwork

Page 1: ......