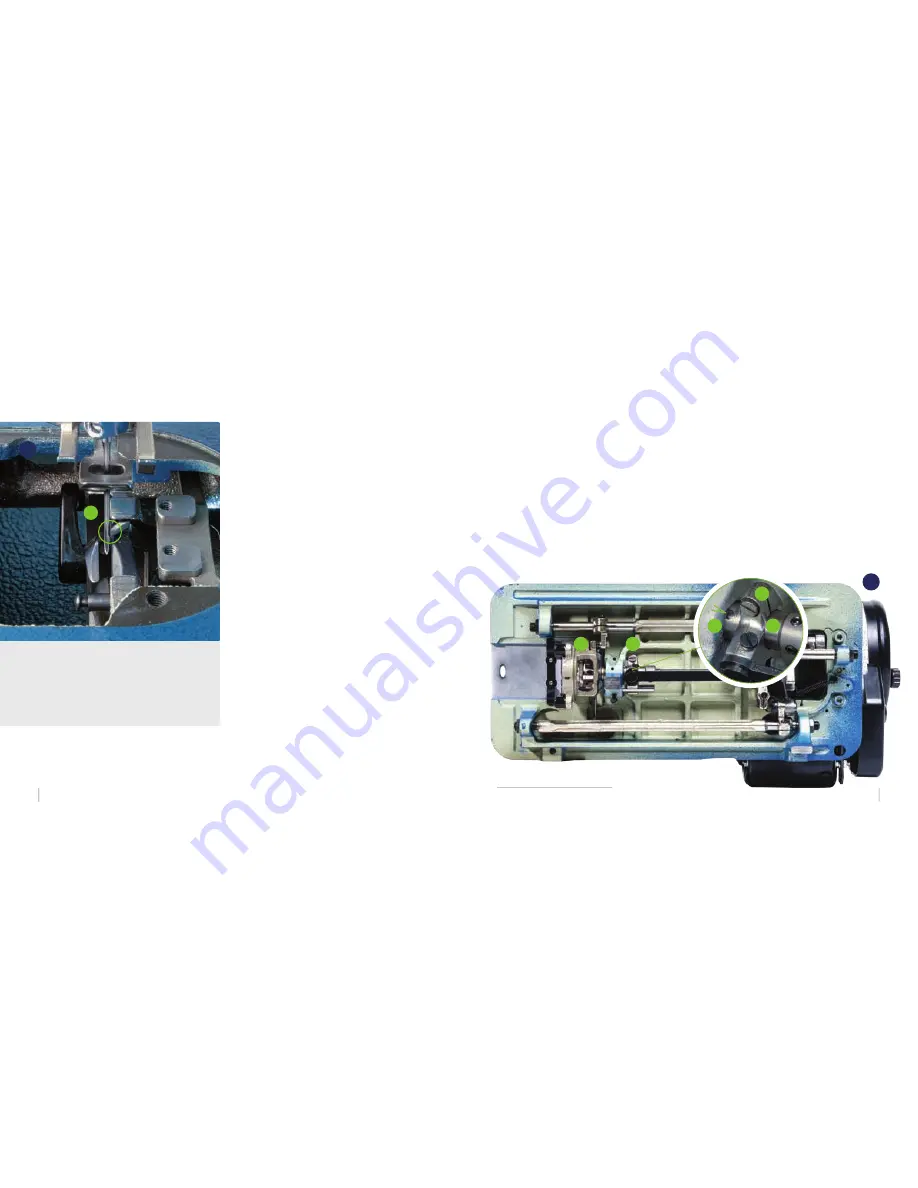

Check the Left-Right Positioning

of the Shuttle Gib Hook

If the shuttle assembly and lower shaft have

slipped left or right of the factory setting, the gib

hook will not be in position to catch the loop.

1.

Re-install the gib hook (p. 30)

2.

Make sure you have a #20 needle

installed.

3.

Set the machine in straight stitch, center

the needle (LSZ-1 only), and grab a

flashlight.

4.

Remove the presser foot, needle plate and

feed dog.

5.

Looking from the top down in to the

machine (

45

), slowly rotate the balance

wheel. As the gib hook swings past the

needle, the hook should be as close as

possible to the right side of the needle

without deflecting it (

A

).

If the gap between the needle and the

hook is too large, the hook must be

moved to the left to close the gap.

If the needle is being deflected by the

hook, then the hook must be moved to

the right.

Adjusting the Left-Right Positioning of the Shuttle Gib Hook

1.

Set the machine to straight stitch.

2.

Make a mark on the cast iron bearing

surface next to the large oil hole

(

46

B

) in the shuttle race guide shaft (

C

).

If the shaft should accidentally rotate,

realign the mark with the oil hole.

3.

Loosen slightly the compressible timing

clamp screw (

D

) on the compressible

timing clamp that drives the entire

assembly back and forth with the zigzag

movement of the needle. Incrementally

loosen the screw until light taps will

move the shuttle assembly (

E

) in either

direction.

4.

Carefully move the assembly to position

the hook as close to the needle as

possible without deflecting (p. 45,

45

).

5.

With the mark on the bearing surface and

oil hole aligned, tighten the compressible

timing clamp screw (

D

).

Applies to LSZ-1 Model Only

>

For the sake of clarity (

45

) shows the machine

without the retaining ring installed. While this

makes it easier to see the timing, the hook

must be held in place with light finger pressure

to keep it from falling out of the shuttle

assembly when rotating the balance wheel.

A

45

46

D

C

D

B

E

Ultrafeed

®

Guidebook: Troubleshooting the Ultrafeed®

46

45

www.sailrite.com