VERS.2021.09.28 CS451_MAN_EN

20

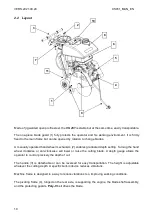

6 MAINTENANCE AND SERVICE

CAUTION: to perform maintenance of the machine, always switch it off. Always wear a mask and

safety goggles while performing the maintenance of machine.

6.1 Maintenance of the machine

To ensure a long-term quality from the cutting with the CS 451, please follow the maintenance plan

below:

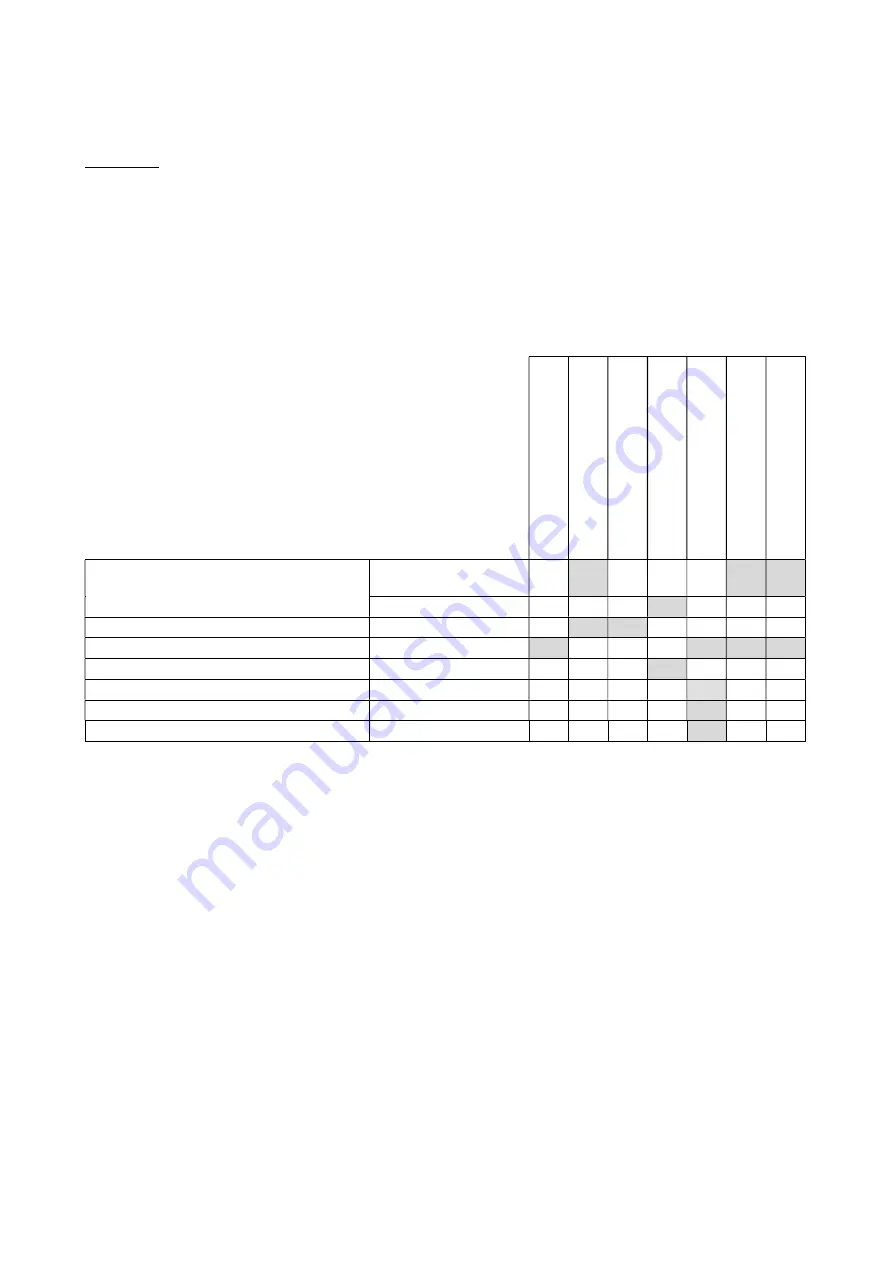

Regular service period

Perform

at

every

indicated period

A

ft

e

r

o

ne

h

ou

r

o

f

w

o

rk

B

e

g

in

n

in

g

o

f

th

e

d

a

y

D

u

ri

n

g

to

o

l c

ha

n

ge

E

n

d

o

f t

h

e

d

a

y

O

n

ce

a

w

e

ek

A

ft

e

r

a

fa

ilu

re

A

ft

e

r

a

d

a

m

a

g

e

Whole machine

Visual control (general

aspect, sealing)

Clean

Flange and blade fixing devices

Clean

Belt tension

Control

Water hoses and nozzles

Clean

Depth screw

Grease

Engine housing

Clean

Reachable nuts and screws

Tighten up

Adjustment and replacement of the belt

After one hour of work, the belt heats up and stretches. Therefore, you have to re-tighten it.

To adjust the belt, firstly remove the belt guard by unscrewing the 4 nuts. Loose the 4 engine bolts

and shift the engine by using the two screws on the front. Then tighten the 4 bolts.

To replace the belt, move the engine completely to the front. Adjust the belt and retighten it by shifting

the motor to the rear. Then tighten the 4 bolts.

Lubrication

The CS 451 uses life-lubricated bearings. Therefore, you don’t need to lubricate them at all.

Grease the depth screw once a week.

Cleaning of the machine

Your machine will last longer if you clean it thoroughly after each working day.