VERS. 2017.06.12

CM 401_MAN_EN

14

Declared value of noise emission following

EN ISO 11201

and

NF EN ISO 3744.

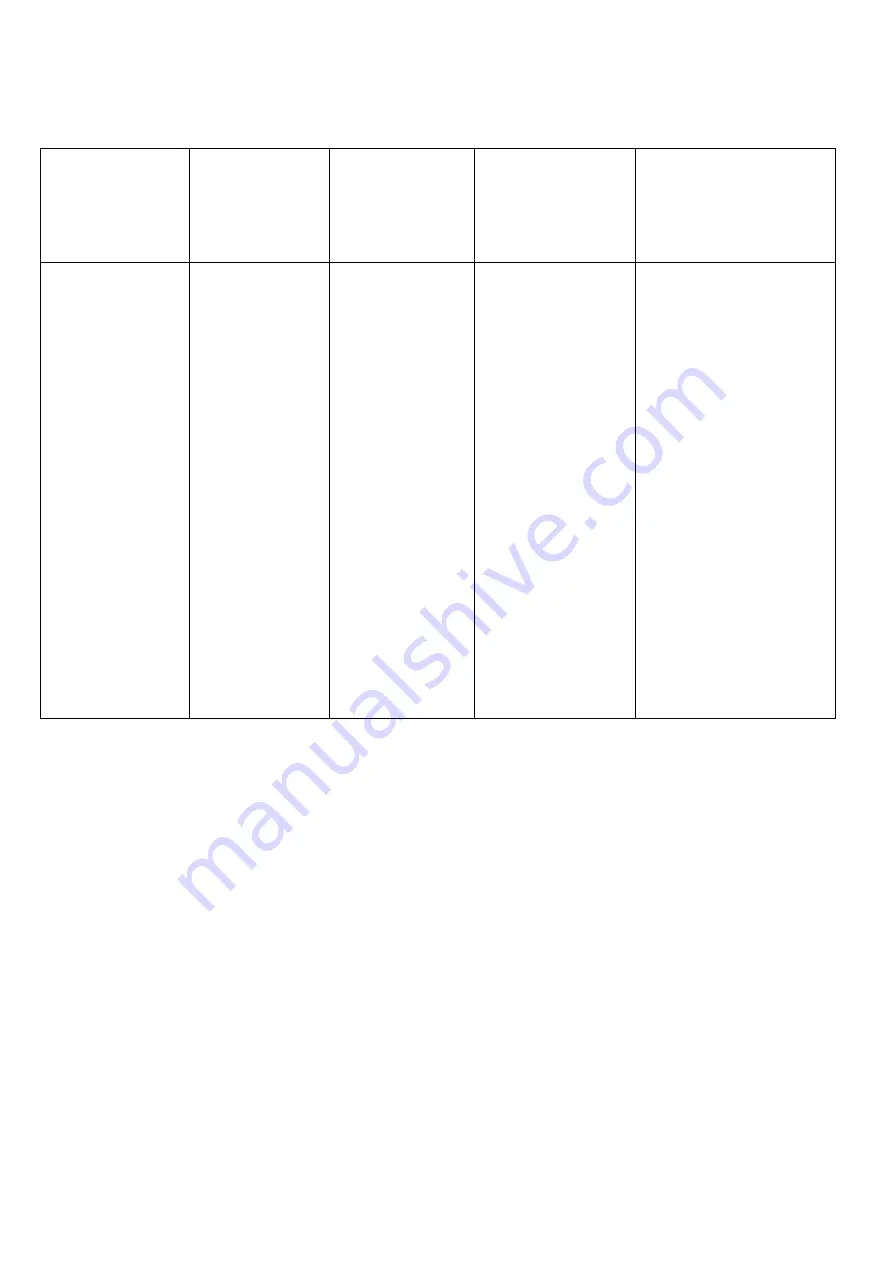

Machine

Model / code

Sound

Pressure level

L

Peq

EN ISO 11201

Uncertainty K

(Sound

Pressure level

L

Peq

EN ISO 11201)

Sound power

level

L

Weq

NF EN ISO 3744

Uncertainty K

(Sound power level

L

Weq

NF EN ISO 3744)

CM 401 500

30.1.230V

70184626981

CM 401 500

40.3.400V

70184626983

CM 401 600

30.1.230V

70184626994

CM 401 600

40.3.400V

70184627004

CM 401 500

30.1.115V

70184627497

CM 401 600

30.1.115V

70184627498

81 dB(A)

2.5 dB(A)

94 dB(A)

4 dB(A)

Values determined using the procedure described in the standard

EN 12418.

The measurements are made with new machines. Actual values may vary with site conditions, in

terms of:

Wear Machine

Lack of maintenance

Inappropriate tool for application

Tool in poor condition

Unskilled operator

Etc…

Measured values relate to an operator in normal use, as described in the manual position.

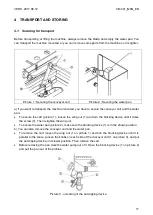

3

ASSEMBLY AND COMMISSIONING

Summary of Contents for Norton Clipper CM 401 Series

Page 1: ...CM 401 OPERATING INSTRUCTIONS Translation of the original instructions...

Page 2: ...VERS 2017 06 12 CM 401_MAN_EN 2...

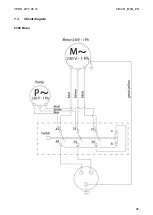

Page 25: ...VERS 2017 06 12 CM 401_MAN_EN 25 7 3 Circuit diagram 230V Motor...

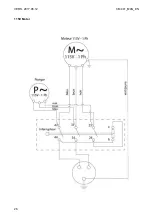

Page 26: ...VERS 2017 06 12 CM 401_MAN_EN 26 115V Motor...

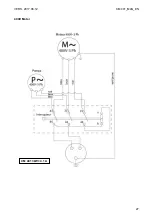

Page 27: ...VERS 2017 06 12 CM 401_MAN_EN 27 400V Motor CM 401 3kW 4 1 A...