VERS. 04.12.2019

MAN CWM 216/254 EN

21

4

BREAKDOWN – CAUSES AND CURES

4.1 Breakdown-finding procedures

Should any breakdown occur during the use of the machine, turn it off, and isolate it from the electrical supply.

Any works dealing with the electrical system or supply of the machine can only be carried out by a qualified

electrician.

4.2 Trouble-shooting guide

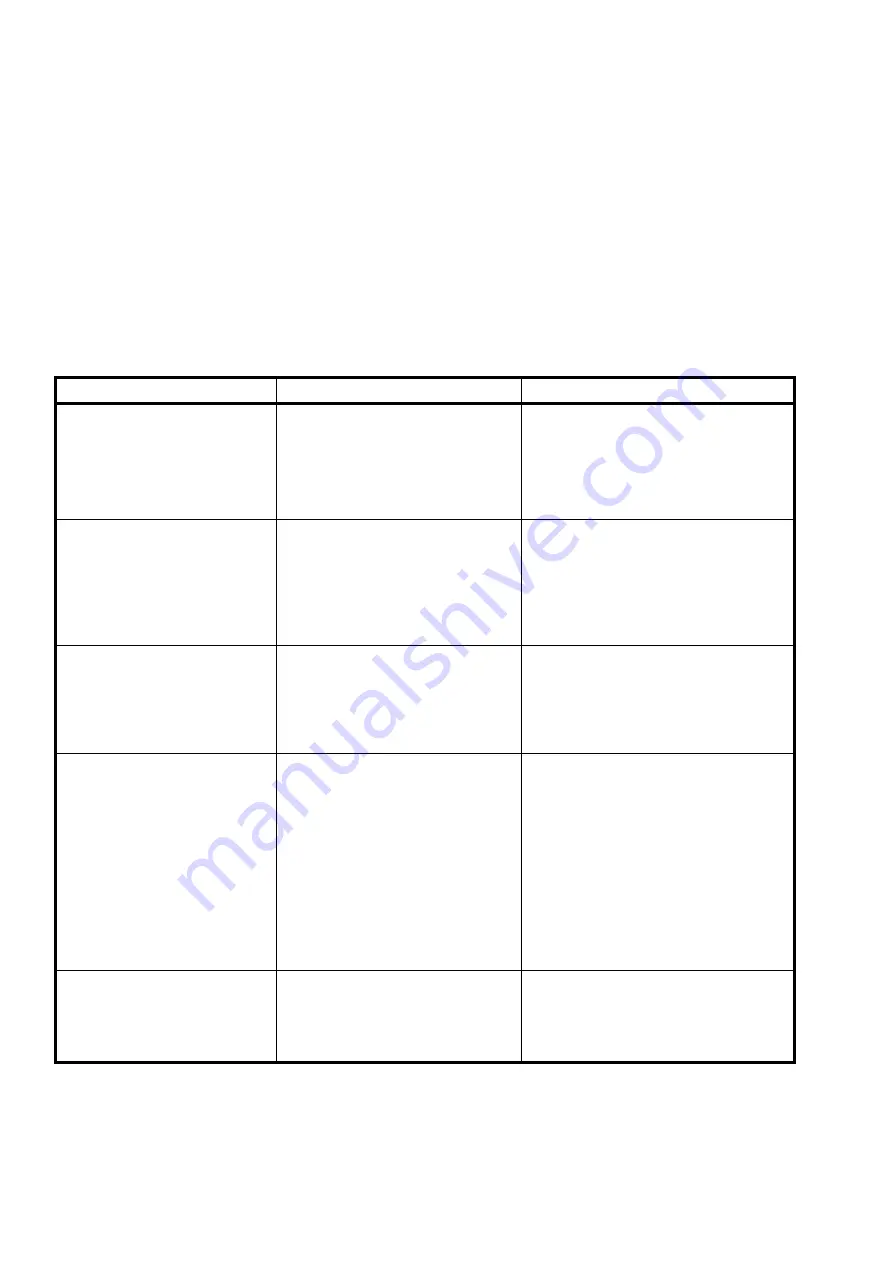

Trouble

Possible source

Resolution

1.Product does not

start

1.1. Not connected to power

supply

1.2. Power cord or plug is

defective

1.3. Other electrical defect to

the product

1.1. Connect to power supply

1.2. Check by a specialist

electrician

1.3. Check by a specialist

electrician

2.Product does not

reach full power

2.1. Extension cord not

suitable for operation

with this product

2.2. Power source (e.g.

generator) has too low

Voltage

2.3. Air vents are blocked

2.1. Use a proper extension

cord

2.2. Connect to another power

Source

2.3. Clean the air vents

3. Product does not

cut

3.1. Not connected to power

supply

3.2. Saw blade is worn or

damaged

3.3. Bevel and mitre angle

incorrectly adjusted

3.1. Connect to power supply

3.2. Replace with new one

3.3. Check and adjust

according to the

instruction manual

4.Unsatisfactory

result

4.1. Dull / damaged saw

blade

4.2. Cutting angle is incorrect

4.3. Saw blade not suitable

for work piece material

4.4. Overheated saw blade

4.5. Workpiece not clamped /

placed properly

4.1. Replace with new one

4.2. Adjust the bevel and / or

mitre cutting angle

4.3. Use proper saw blade

4.4. Let the work cool down

before using again

4.5. Clamp / place the

workpiece properly before

cutting

5. Excessive

vibration or noise

5.1. Saw blade is dull/

damaged

5.2. Bolts/nuts are loose

5.1. Replace with a new one

5.2. Tighten bolts/nuts