◆8.

If you find such phenomena described below, there is possibility of dry superheating. STOP the

operation immediately to avoid additional damage.

#Even though the heating power of the burner is still strong and stable...

- Pressure doesnʼ t increase.

- Engine RPM decreases.

- Steam from the exhaust pipe is reduced.

# Pale flames are coming out of the stack.

# Abnormal smell or smoke is observed.

NOTE

◇1.

The safety valve for the boiler works at the pressure of 2kgf/cm2. The safety valve (RED colored) for

the burner works at the pressure of 1.5kgf/cm2. The operator must pay close attention to

pressures which exceed these norms.

◇2.

Always confirm that the safety valves are functioning freely by depressing the springs when filling

the water supply and fuel supply.

◇3.

Closing the needle valve will extinguish the flame and shut down the operation.

◇4.

Because carbon tends to collect on the nozzles, clean the nozzles after every ten operations using

the attached wire.

*Do not use a wire other than the attached one to clean the nozzles as any thick wire may reduce

the heating power by widening the nozzle hole. Also, clean the nozzles from the nozzle end

(boiler side). Do not loosen the screws of [E].

◇5.

About heating power weaknesses, refer to the Causes and Countermeasures listed below

◇6.

The wick end should always reach the bottom of the burner to ensure steady fuel flow and flame.

If the wick does not touch the bottom, heating power will be reduced. In such cases, push the

wick down gently using a wire or similar object. Standard burning time is about 25 minutes. If

burning time is over 25 minutes, it means that heating power is reduced and the operator must

find and fix the cause(s).

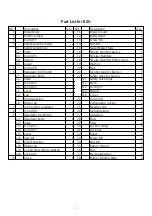

Possible cause

Fuel absorbed moisture

Excessive dust or

carbon in nozzle

Foreign matter prevents

valve from closing

Countermeasure

Replace remaining fuel with new alcohol.

Clean using wire provided. After removing the gland nut and

needle, pass the wire through the holes in the nozzle.

When gas leakage is caused by something preventing the valve

from closing completely, clean it completely

- 4 -

All specifications and models are subject to change without notice.

http://www.saito-mfg.com

SAITO SEISAKUSHO CO., LTD.

22-7, 3-chome, Tokagi, Ichikawa-shi, Chiba prefecture 272-0024, Japan

Phone: 047-378-4156 FAX: 047-378-4155

Summary of Contents for B2G

Page 6: ...6...