8

N O R M A L

E N G I N E O P E R A T I O N

3.

After obtaining the proper idle

setting, the low rpm setting may be

made through the positioning of the

throttle adjustment screw, if applicable.

If

not, adjust the idle setting via the

throttle trim of your transmitter.

Normal Engine

Operation

If break-in was accomplished on a test

bench your engine may be mounted to

the aircraft and flown. The initial flight

should be performed with the engine

adjusted for a rich fuel mixture.

1. Your Saito engine should be

securely mounted to the aircraft. There

are many motor mounts available;

however, a high-quality metal mount,

such as those manufactured by Saito

exclusively for Saito engines, is

considered to be the best.

2.

General operating procedures that

will ensure long engine life are:

Do not

operate the engine with a

‘‘lean’’ mixture.

Regularly check all screws and nuts

on

both the engine and muffler.

After 1 to 2 hours of operation, valve

adjustment may be necessary. Adjust

the valves as shown in the “Engine

Maintenance” section.

The Saito engines are equipped with

a breather nipple

(19).

It is

recommended that a length

of

silicone tubing be attached to this

crankcase breather nipple

(19)

and

routed away from the engine

compartment so the excess oil can be

expelled outside of the aircraft.

Engine Maintenance

Do not needlessly dismantle your

Saito single cylinder engine.

If you must disassemble your single

cylinder engine, please refer to the

following steps. Remember, a qualified

individual should do disassembly.

1. Cylinder screws should be loosened

in a criss-cross pattern.

2.

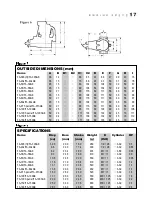

Assemble the cam gear lining up the

timing mark at the

“6

o’clock’

position. The crankshaft must be

positioned at the “12 o’clock’ or

“top dead center” (TDC) position

(refer to Figure

I

below).

Figure

1

Cam (Intake or Exhaust)

Bench Mark

Summary of Contents for FA-30S Golden Knight

Page 1: ...Version 2005...

Page 24: ...J a n1 1 2 0 0 5...