E N G I N E

O P E R A T I O N

3.

Reassemble the piston, rod, rocker

arm, pins,

tappet, etc., in their

original positions. Engine parts are

mated after running the engine and

they must be reassembled as close as

possible to their original position.

4.

Assemble the engine, reversing the

criss-cross pattern used in the

disassembly. Prior to tightening each

of the screws, apply a drop of oil to

prevent thread damage.

Normal

engine

maintenance, such

as

adjusting the valves or carburetor

maintenance, is permissible without

voiding the warranty.

If you have

any questions concerning

maintenance procedures, please

contact the Saito Service Center at

(217) 355-9511.

Our technicians will

be happy to advise you

on

maintenance issues.

Valve/Tappet

Gap

Adjustment

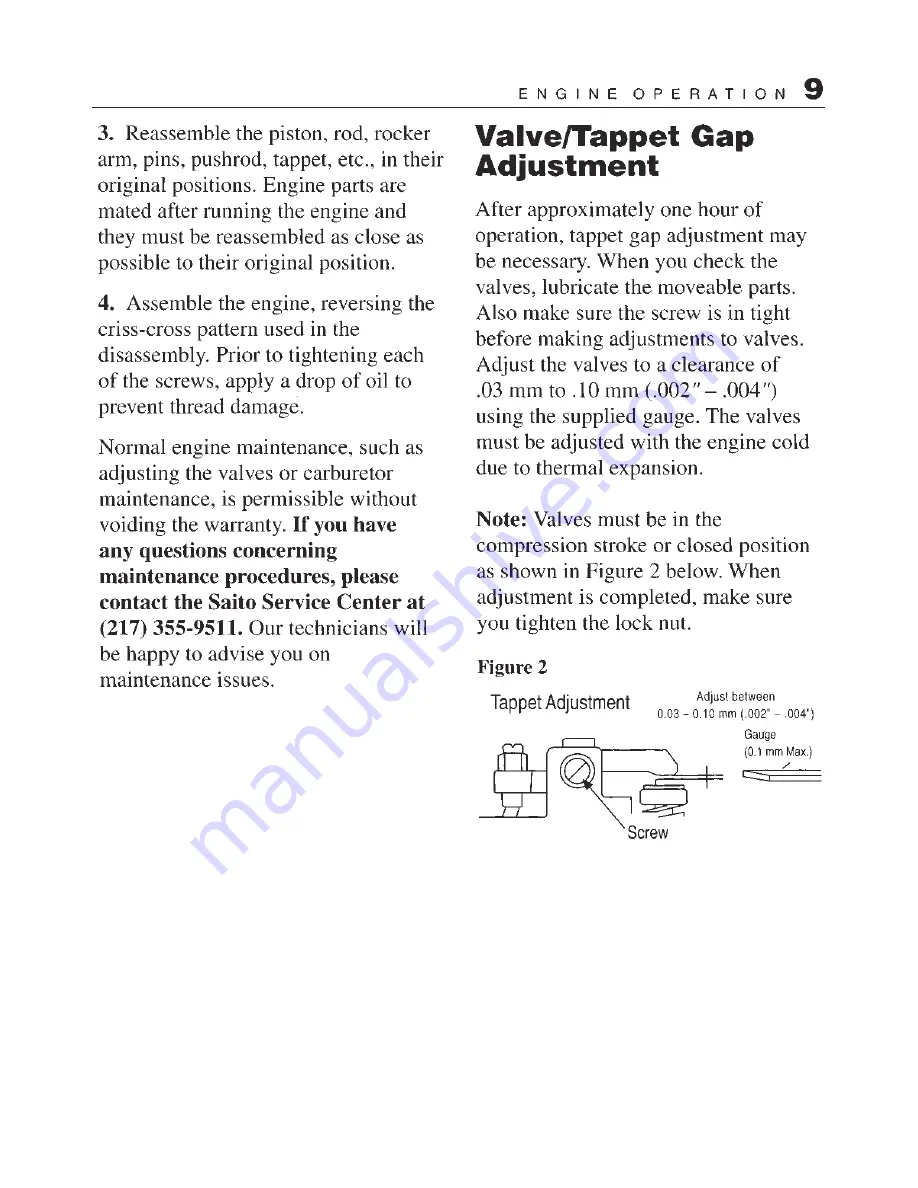

After approximately one hour of

operation, tappet gap adjustment may

be necessary. When you check the

valves, lubricate the moveable parts.

Also make sure the screw is in tight

before making adjustments to valves.

Adjust the valves to a clearance of

mm to

mm

using the supplied gauge. The valves

must be adjusted with the engine cold

due to thermal expansion.

Note:

Valves must be in the

compression stroke or closed position

as shown in Figure

2

below. When

adjustment is completed, make sure

you tighten the lock nut.

‘Screw

Tappet Adjustment

Adjust between

0.03 - 0.1 mm (.002" - .004")

Gauge

(0.1mm Max)

Figure 2

Summary of Contents for FA-30S Golden Knight

Page 1: ...Version 2005...

Page 24: ...J a n1 1 2 0 0 5...