34

F G - 3 0 / F G - 3 6 P A R T S L I S T

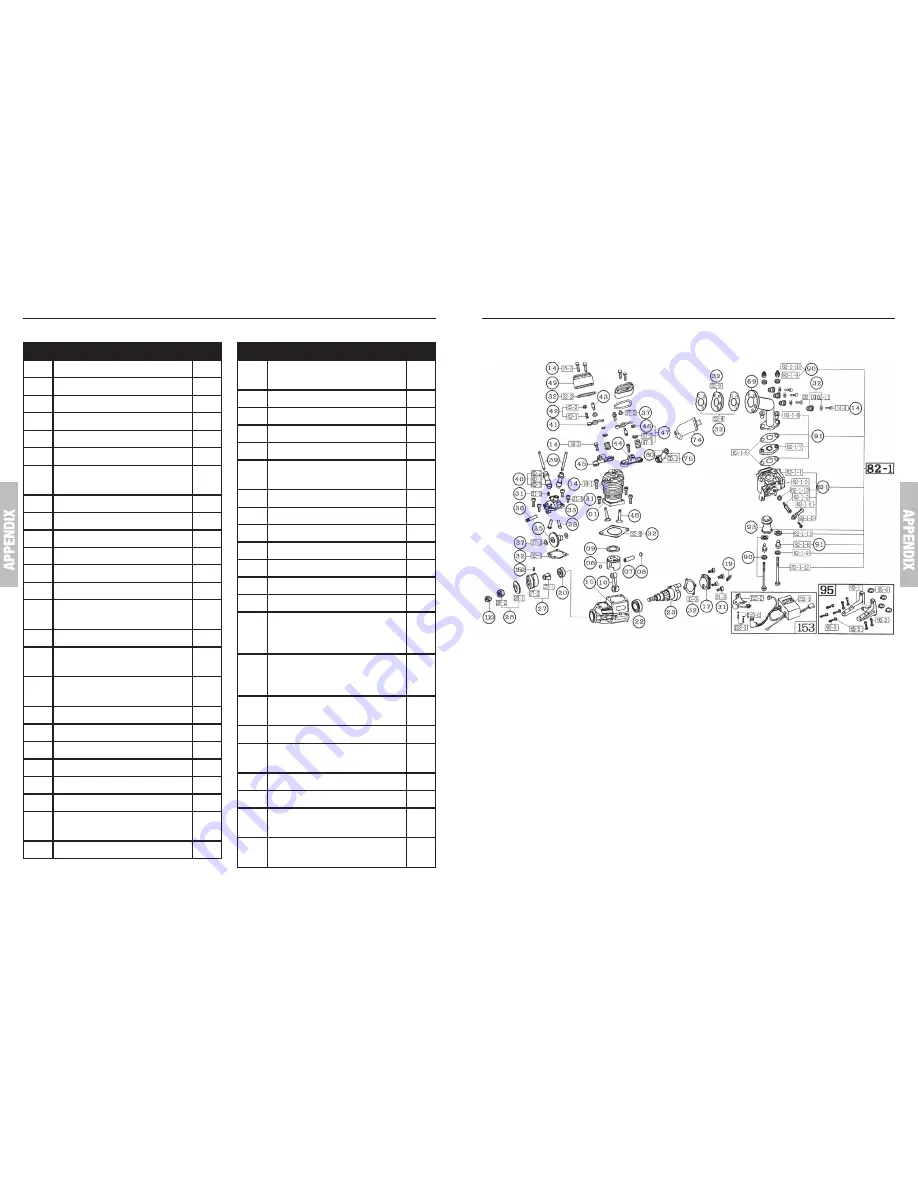

F G - 3 0 / F G - 3 6 E x P L O D E D V I E W

35

#

DESCriPTiOn

QTY

01

Cylinder (left)

1

06

Piston

1

07

Piston Pin

1

08

Piston Pin Retainar

2

09

Piston Ring

1

10

Connecting Rod

1

14

Cylinder Screw Set

(14-1, 14-2, 14-3, 14-4)

1set

15

Crankcase

1

17

Rear Cover

1

19

Breather Nipple

1

20A

Front Bearing

1

22

Rear Bearing

1

23

Crankshaft

1

27A

Taper Collet and Drive Flange

(27-1, 27-2)

1ea

28

Prop Washer and Nut (28-1,28-2)

1ea

31

Crankcase Screw Set

(31-1, 31-2, 31-3)

1set

32

Engine Gasket Set

(32-1, 32-2, 32-3, 32-4)

1set

33

Cam Gear Housing

1

35

Cam Gear

1

36A

Cam Gear Shaft

1

37

Steel and Washer Set (37-1, 37-2)

1set

38

Tappet

2

39

Pushrod

2

40

Pushrod Cover and Rubber Seal

(40-1, 40-2, 40-3)

2ea

41

Rocker Arm

2

#

DESCriPTiOn

QTY

42

Rocker Arm Screw and Nut

(42-1,42-2)

2ea

43

Rocker Arm Pin

2

44

Rocker Arm Bracket (Left)

1

45

Rocker Arm Bracket (Right)

1

46

Valve (In and Out) (46-1, 46-2)

2

47

Valve Retainer

(47-1,47-2,48)

2ea

48

Valve Retainer (Cotter)

4

49

Rocker Arm Cover

2

69

Intake Manifold

1

74

Muffler

1

75

Muffler Manifold (75-1, 80)

1

80

Muffler Nut

2

82-1 Carburetor Complete

1set

83-1 Carburetor Body Assembly

(82-1-1, 82-1-2, 82-1-3, 82-1-4,

82-1-5)

1set

90

Carburetor Screw and Spring Set

(82-1-9, 82-1-10, 82-1-11,

82-1-12)

1set

91

Carburetor Gasket Set

(82-1-6, 82-1-7, 82-1-8)

1set

93

Intake Velocity Stack

1

95

Engine Mount Set

(95-1, 95-2, 95-3, 95-4, 95-5)

1set

110

Anti Loosening Nut

1

149

Oil Slinger

1

152

Screw-Pin (for Drive Flange

Setting)

1

153

Electronic ignition system

(153-1, 153-2, 153-3, 153-4)

1set

Saito FG-30/FG-36 Parts List

Saito FG-30/FG-36 Exploded View