6

2

.1.

3

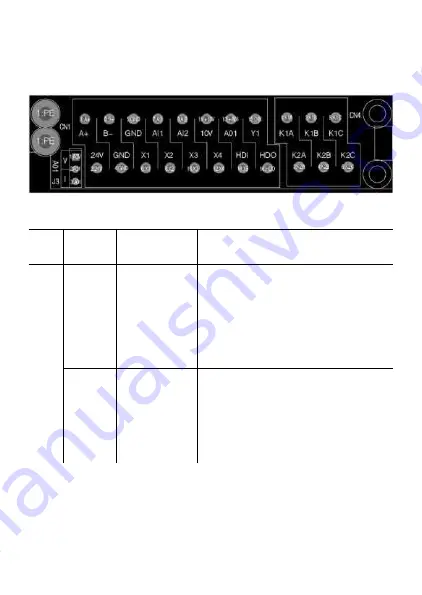

控制端子说明

Control terminals instruction

控制回路端子布置图如下示

:The control circuit terminals layout diagram shown as the below:

2.1.4

控制端子功能说明

Control terminal function instruction:

类别

Category

端子符号

Terminal

symbol

端子名称

Terminal

name

功能说明

Function instruction

电源

Power

supply

10V-GND

外接

10V

电源

Outer

connect 10V power

supply

向外提供

+10V

电源,最大输出电流:

Outer provide

+10V power supply, the max output current:

150mA

(带短路保护)一般用作外接电位器工作 电

源,电位器阻值范围:

1kΩ

〜

5kΩ Generally, 150mA

(with short circuit protection) used as the working

power supply of outer connect electric potential

device, electric potential device electric resistance

value range: 1kΩ

〜

5kΩ

24V-GND

外接

24V

电源

Outer

connect 24V power

supply

向外提供

+24V

电源,一般用作数字输入输出端 子

工作电源和外接传感器电源

Outer p24V

power supply, generally, it used as working power

supply of digit input and output terminal and outer

connect sensor power supply

最大输出电流:

200mA The max output current:

200mA