Servi

cing and

Maintenance

Page 2

7

1. Check the water quality regularly. The strainer must be cleaned to prevent

water system choke.

2. The location of the installation should be clean and well ventilated. Clean the

condenser heat exchanger regularly 9 every 1~2 months).

3. Check the make up water supply and pressure relief valve frequently to ensure

it is in good condition.

4. Ensure the electrical components and wiring are connected properly and firm.

5. If the unit is not operating for a long period, the water must be drained out and

cut off the power supply. Use a sheath to cover the unit.

6. To restart the unit after long period not operating, fill in clean water, and check

properly. Let the unit warms up 6 hours before switch on the unit to ensure the

unit is in good condition.

7. Check the working pressure regularly to ensure no gas is leaking. When gas

leak occurs, adding new refrigerant into system must be done by service

personnel. For R410A refrigerant, do not add new refrigerant to the system.

Please vacuum the system thoroughly before recharging the R410A in liquid

phase.

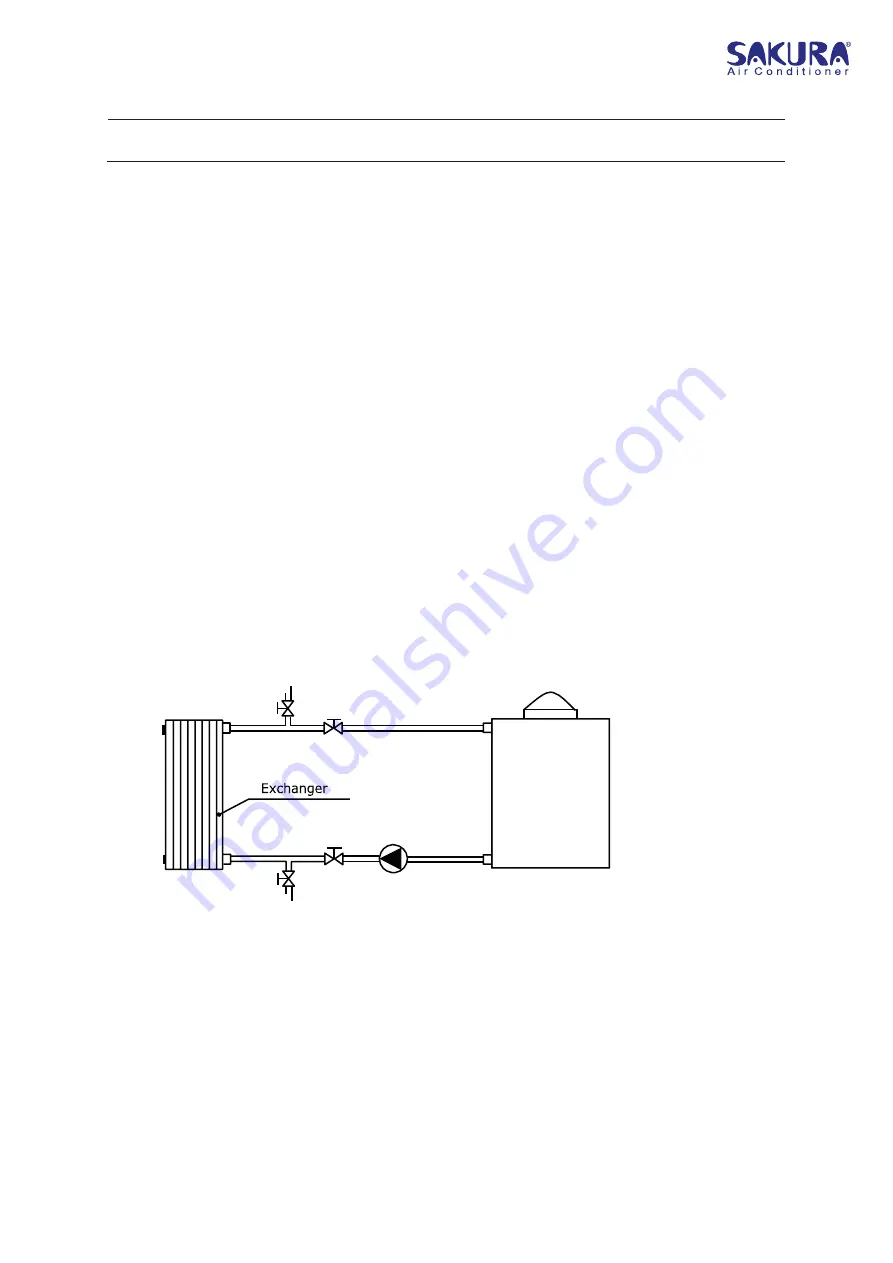

8. It is recommended that heat exchanger should be cleaned at least once within

a year. Close monitoring is required if the water quality is bad.

a) It is recommended clean the heat exchanger by using acid cleaning

agents like phosphoric acid (5% concentration).

b) The solution flow rate should be 1.5 higher than the water flow rate.

Counter flow will clean the heat exchanger effectively.

c) After cleaning process complete, flush lot of clean water to remove the

excess acid.

Acid

cleaning

agents

Heat

Summary of Contents for FCA 201

Page 1: ...Ref S FR 266 11 19 Models FCA 201 601 AIR COOLED MODULAR CHILLER ...

Page 6: ...Page 5 Operating Range Cooling ...

Page 7: ...System Schematic Diagram Page 6 Model FCA201 301 401 501 601 ...

Page 17: ...Dimensions Page 16 Model FCA201 301 Model FCA401 ...

Page 18: ...Page 17 Model FCA501 601 ...

Page 25: ...Page 24 FCA201 301 401 501 601 Maintenance Maintenance ...