EN |

7

AMBERAIR COMPACT S-CX v2023.3

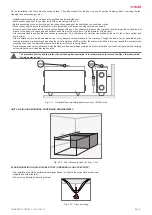

3.5. MECHANICAL DESIGN

The AmberAir Compact is available in 2 sizes.

The outer panel is painted in RAL7040. The handles are black. Internal surface: galvanized plated sheet steel. Corrosion resistance class C3.

Panel insulation thickness – 50 mm (mineral wool).

AmberAir Compact is equipped with bag filters ePM10 65% (M5) and ePM1 55% (F7).

The supply air and extract air fans have backward-curved blades. The fans are direct-driven with a variable speed control.

Casing parameters: D1 (M), L1 (M), F9, T2, TB2.

3.6. INTENDED USE

Air handling units are designed to provide ventilation in premises and depending on settings, passive heat recovery, air heating or “free cooling”.

Sound levels exceeding 60 dB(A) may occur depending on load and unit size (see select.salda.lt for detailed information).

The unit is equipped with a heat exchanger and a heater (or cooler) to compensate for heating/cooling losses during room ventilation, so we do

not recommend using the unit as the main source of room heat/cold. The unit may not reach the set supply air temperature if the actual room

temperature differs significantly from the desired one, as this will cause the heat exchanger to operate inefficiently.

The device is not designed to transport solid particles by air. The device must not be operated in rooms where there is a risk of explosive gases

being released.

We recommend not to switch off the device during the first year of operation, but to leave it operating in the minimum (20%) mode. Due to the

moisture in the structures of the new building, condensation is possible both inside and outside the unit. Continuous operation of the device will

significantly reduce the risk of condensation.

We recommend that you always keep the appliance switched on, as this will ensure a good indoor climate and reduce the risk of condensation on

the walls. The device can be switched off when a service inspection is performed or filters are changed.

If the unit is installed in a room with high humidity, there is a high potential for condensation to form on the walls of the unit in cold weather outdoors.

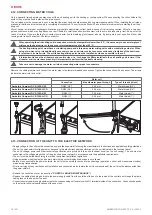

3.7. AIR HANDLING UNIT CONTROL

AmberAir Compact units have integrated efficient microcontroller-based MCB controllers. All unit‘s active components are controlled by the MCB

controller. It has a lot of functions that can efficiently operate the air handling unit. Users have access to the controller configuration where the

control settings can be changed, or new controllable devices can be added to the air control system. Users can also connect to the controller and

monitor unit‘s status or change preferred environment settings.

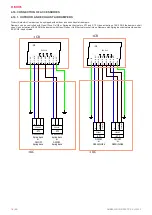

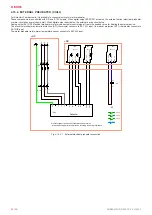

3.8. COMMUNICATION INTERFACE

Air handling unit can be controlled with a remote-control panel, WEB interface or mobile app via MB-Gateway and BMS (building management

system). More information is provided in the table below.

With MB-GATEWAY

Remote control panels

BMS direct connection

Wireless communication

Web interface

SALDA AIR mobile application

BMS over Modbus TCP/IP

BMS over BACnet IP

ST-SA-Control

Modbus RTU (RS485)

MB-G WIFI router

Modbus RTU connects to X8 terminal block of MCB controller (see section

“CONNECTION TO WIRING TERMINALS”

). By default, the con-

troller is configured with RS485 port settings:

Baud rate: 19200 bps

Data: 8 Bit

Parity: Even

Stop bit: 1

Modbus address: 1