16

| EN

RIRS 1200-5500 H EKO 3.0 v2019.06

20 Motor2

04h_Read_Input

16

1

Motor2 fan speed value

0-3

Temperature sensor value

real

format (-3.3E38 - 3.3E38) example: 0h->0C, 7FFFh->3276.7C, 8000h->3276.8, FFFFh->-0.1C

21 Tlimit

04h_Read_Input

0

1

Supply air temperature value

Hex: E0

22 Texhaust

04h_Read_Input

1

1

DTJ(100) temperature sensor value

Hex: E0

23 Textract

04h_Read_Input

2

1

Exhaust air temperature sensor value

Hex: E0

24 ToutDoor

04h_Read_Input

3

1

Ouside air temperature sensor value

Hex: FFEC

25 Twater

04h_Read_Input

12

1

Return water temperature sensor value

Hex: FFEC

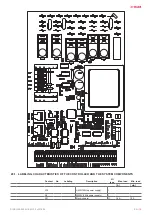

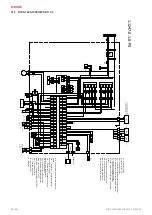

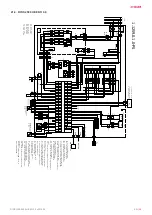

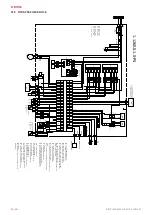

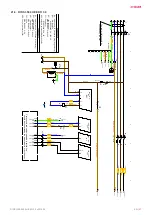

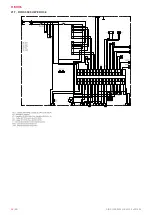

19.4. ELECTRICAL CONNECTION OF THE HVAC UNIT

Electrical connection can only be implemented by the qualified electrician in accordance with the applicable international and national electrical

safety requirements and requirements for installation of electrical devices.

Use only power source which meets the requirements specified on the device label.

Power supply cable should be selected based on the electrical specification of the device. If the device power supply line is far from the unit, the

distance and voltage drop should be considered.

Device must be earthed.

Install the control panel at the designated place.

Install the supplied connection cable(FLEX controller) between the control panel and the HVAC unit. It is recommended to install the control panel

separately from the power cables.

Note:

If cable is used together with other power cables, shielded control panel cable with earthed shield should be used.

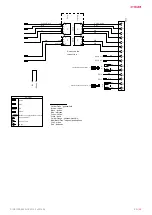

Connect the plug (RJ10 type) to the RS485-1 socket of the unit. Connect the other end to the control panel.

RS458_1 RS458_2

NOTE:

The remote control panel can be connected and (or) disconnected only after disconnecting the power supply for the HVAC unit.

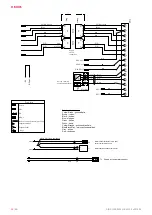

Switch on the mains voltage, switch on the blade switch Q, see

Fig. 5

(actual appearance of the blade switch can be different from the given photo

based on the model of the product).

OFF

ON

Select the desired fan rotation speed and the supply air temperature using the remote controller.

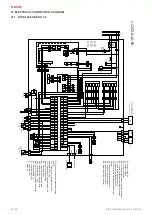

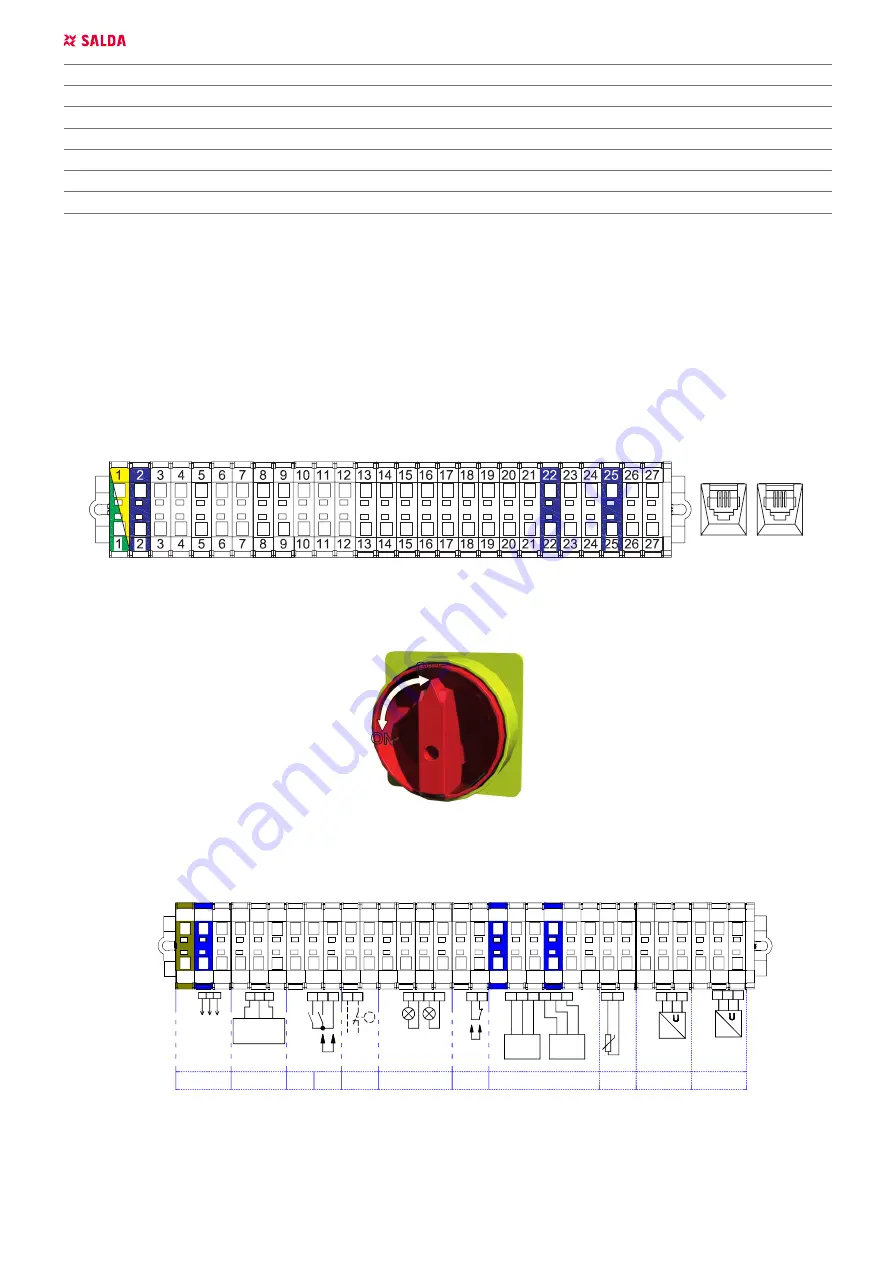

19.5. SYSTEM ADJUSTMENT GUIDELINES

X16

B

OOS

T

S

TA

RT

-NC

ST

O

P-

N

O

Jumper

CO2; Extract air pressure

Air quality transmitter

Supply air pressure

Transmitter 2

26 - 24V DC,

27 - intput, 0-10V DC,

28 - GND,

X16.10

28

27

P

26

27 28

26

24 25

23

CE7/7

27 28

26

24 25

23

X16.7

PE N L1

L1

N

PE

L1

N

PE

L1

N

PE

1f, 230V AC

Power

supply cable

valve actuator

Water cooler

1

3

2

X16.1

Y1 Y2 G

M5

24VAC, 3-position

Y1 - OPEN (24VAC)

Y2 - CLOSE (24VAC)

G - System potential 24VAC

1 2 3 4 5 6 7 8 9 10

10

9

8

7

6

5

4

3

2

1

Boost

Start/Stop

AHU status

AHU work

AHU stop

24V

D

C

24V

D

C

3

1

P

DX Cooling

X16.4

X16.4

X16.2

13 14

8

7

X16.3

AH

U

st

op

1.

2W

m

ax

4 5 6

10

9

X16.4

1.

2W

m

ax

AHU

wo

rk

11 12

25

24

23 - 24V DC,

24 - intput, 0-10V DC,

25 - GND,

Transmitter 1

P

23

18 19 20 21 22

22

21

20

19

18

17

16

15

14

13

12

11

NTC

Supply air

TJ

temp.sensor

21 22

X16.6

11 12 13 14 15 16 17

N

L

19

X16.5

M2

M3

17 18

L

N

N L L

16

20

15

230V AC

230V AC

ON/OFF

ON/OFF

L c

ont

rol

N

L c

ont

rol

L

Supply air

Extract air

damper actuator

damper actuator

Fire alarm

input

Air quality transmitter

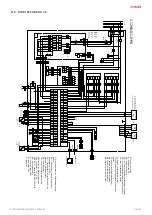

X16

X16

Air quality transmitter

Fire alarm

input

damper actuator damper actuator

Extract air

Supply air

L

L c

ont

rol

N

L c

ont

rol

ON/OFF

ON/OFF

230V AC

230V AC

15

20

16

L

L

N

N

L

18

17

M3

M2

X16.5

19

L

N

17

16

15

14

13

12

11

X16.6

22

21

temp.sensor

TJ

Supply air

NTC

11 12 13 14 15 16 17 18 19 20 21 22

22

21

20

19

18

23

P

Transmitter 1

23 - 24V DC,

24 - intput, 0-10V DC,

25 - GND,

24 25

12

11

AHU

wo

rk

1.

2W

m

ax

X16.4

9 10

6

5

4

1.

2W

m

ax

AH

U s

to

p

X16.3

7 8

14

13

X16.2

X16.4

X16.4

DX Cooling

P

1

3

24V

D

C

24V

D

C

AHU stop

AHU work

AHU status

Start/Stop

Boost

1 2 3 4 5 6 7 8 9 10

10

9

8

7

6

5

4

3

2

1

Y1 - OPEN (24VAC)

Y2 - CLOSE (24VAC)

G - System potential 24VAC

24VAC, 3-position

M5

G

Y2

Y1

X16.1

2 3

1

Water cooler

valve actuator

supply cable

Power

1f, 230V AC

PE N L1

PE N L1

PE N L1

L1

N

PE

X16.7

23

25

24

26

28

27

CE7/7

23

25

24

26

28

27

26

P

27 28

X16.10

26 - 24V DC,

27 - intput, 0-10V DC,

28 - GND,

Transmitter 2

Supply air pressure

Air quality transmitter

CO2; Extract air pressure

Jumper

ST

O

P-

N

O

S

TA

RT

-NC

B

OOS

T

X16

X16

Air quality transmitter

Fire alarm

input

damper actuator damper actuator

Extract air

Supply air

L

L c

ont

rol

N

L c

ont

rol

ON/OFF

ON/OFF

230V AC

230V AC

15

20

16

L

L

N

N

L

18

17

M3

M2

X16.5

19

L

N

17

16

15

14

13

12

11

X16.6

22

21

temp.sensor

TJ

Supply air

NTC

11 12 13 14 15 16 17 18 19 20 21 22

22

21

20

19

18

23

P

Transmitter 1

23 - 24V DC,

24 - intput, 0-10V DC,

25 - GND,

24 25

12

11

AHU

wo

rk

1.

2W

m

ax

X16.4

9 10

6

5

4

1.

2W

m

ax

AH

U s

to

p

X16.3

7 8

14

13

X16.2

X16.4

X16.4

DX Cooling

P

1

3

24V

D

C

24V

D

C

AHU stop

AHU work

AHU status

Start/Stop

Boost

1 2 3 4 5 6 7 8 9 10

10

9

8

7

6

5

4

3

2

1

Y1 - OPEN (24VAC)

Y2 - CLOSE (24VAC)

G - System potential 24VAC

24VAC, 3-position

M5

G

Y2

Y1

X16.1

2 3

1

Water cooler

valve actuator

supply cable

Power

1f, 230V AC

PE N L1

PE N L1

PE N L1

L1

N

PE

X16.7

23

25

24

26

28

27

CE7/7

23

25

24

26

28

27

26

P

27 28

X16.10

26 - 24V DC,

27 - intput, 0-10V DC,

28 - GND,

Transmitter 2

Supply air pressure

Air quality transmitter

CO2; Extract air pressure

Jumper

ST

O

P-

N

O

S

TA

RT

-NC

B

OOS

T

X16

1_789.0046A.0.1.2-L-0k

1_789.0046A.0.1.2-L-0k

1_789.0046A.0.1.2-L-0k

FA

NC

Jumper

FA

NC

Jumper

FA

NC

Jumper

Figure 19.5.1. RIRS 1200-1900 HE EKO 3.0

Summary of Contents for RIRS EKO 3.0 1200 HE

Page 1: ...RIRS 1200 5500 H EKO 3 0 EN MOUNTING AND INSTALLATION INSTRUCTION ...

Page 28: ...28 EN RIRS 1200 5500 H EKO 3 0 v2019 06 21 7 RIRS 3500 HW EKO 3 0 ...

Page 37: ... 37 RIRS 1200 5500 H EKO 3 0 v2019 06 ...

Page 38: ...38 RIRS 1200 5500 H EKO 3 0 v2019 06 ...