EN |

11

RIS 400-700 P EKO 3.0 v2019.06

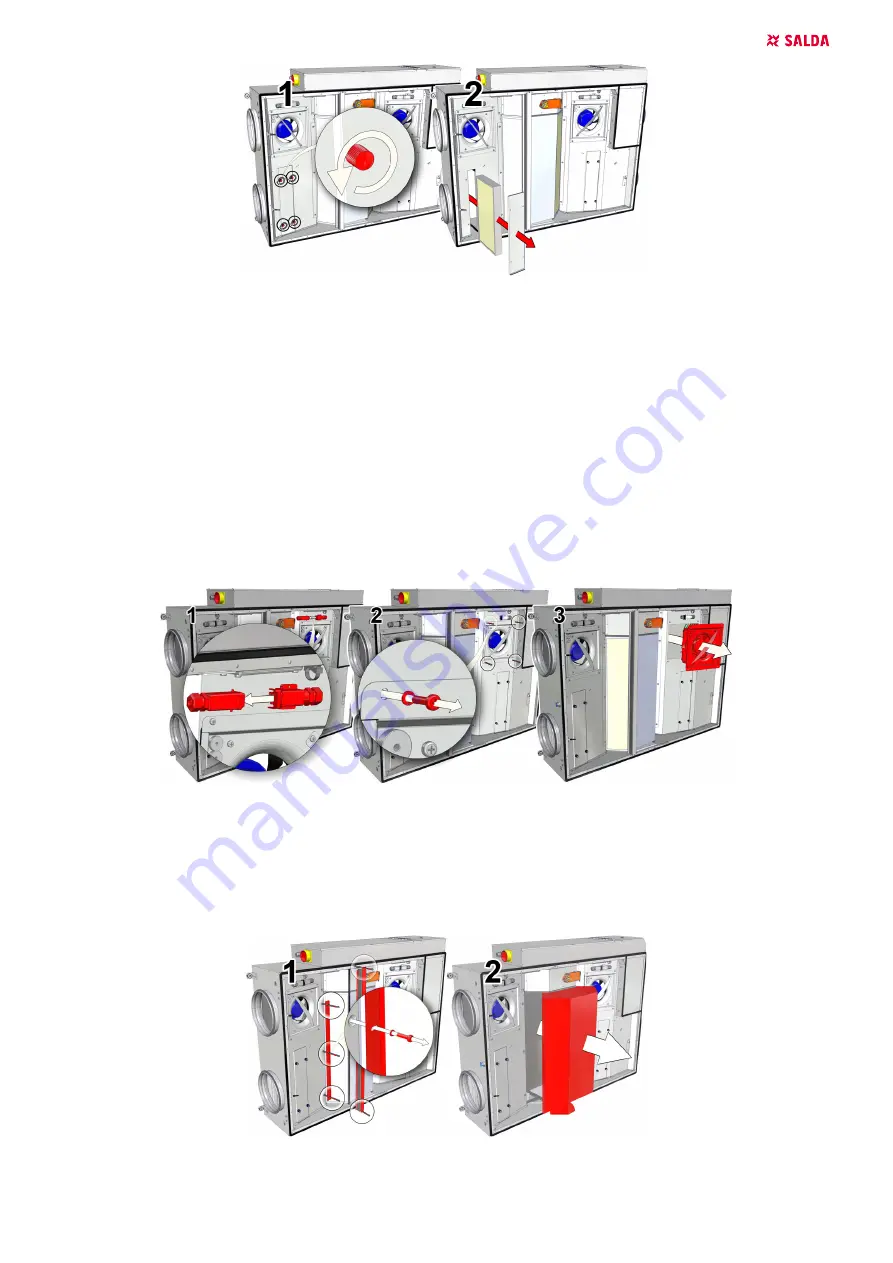

18.2. FAN

- Maintenance and repair should only be performed by experienced and trained staff.

- The fan should be inspected and cleaned if needed at least 1/year.

- Be sure the fan is disconnected from power source before performing any maintenance or repair.

- Proceed to maintenance and repair after any rotation in the fan stopped.

- Observe staff safety regulations during maintenance and repair.

- The motor is of heavy duty ball bearing construction. The motor is completely sealed and requires no lubrication for the life of the motor.

- Detach fan from the unit.

- Impeller should be specially checked for buil-up material or dirt which may cause an imbalance. Excessive imbalance can lead to accelerated

wear on motor bearings and vibration.

- Clean impeller and inside housing with mild detergent, water and damp, soft cloth.

- Do not use high pressure cleaner, abrasives, sharp instruments or caustic solvents that may scratch or damage housing and impeller.

- Do not plunge impeller into any fluid.

- Make sure, that impeller’s balance weights are not moved.

- Make sure the impeller is not hindered.

- Mount the fan back into the unit. Connect the fan to power supply source.

- If the fan does not start after maintenance or repair, contact the manufacturer.

18.3. HEAT EXCHANGER

- Be sure the fan is disconnected from power source before performing any maintenance or repair.

- Proceed to maintenance and repair after any rotation in the fan stopped.

- Clean it once a year.

- Firstly take out heat exchanger cassette carefully. Submerge it into a bath and wash with warm soapy water (do not use soda). Then rinse it with

hot water and let it to dry up.