11

Smarty 3X VE / Smarty 3X VE 3.0

www.salda.lt

• Installing should be performed only by qualified and trained staff.

• The unit should be mounted on the flat horizontal surface so that the product is not leaning.

• When connecting air ducts, consider the notices indicated on the casing of the unit.

• Before connecting to the air duct system, the connection openings of ventilation system air ducts should be closed.

• When connecting air ducts, consider the directions of air flow indicated on the casing of the unit.

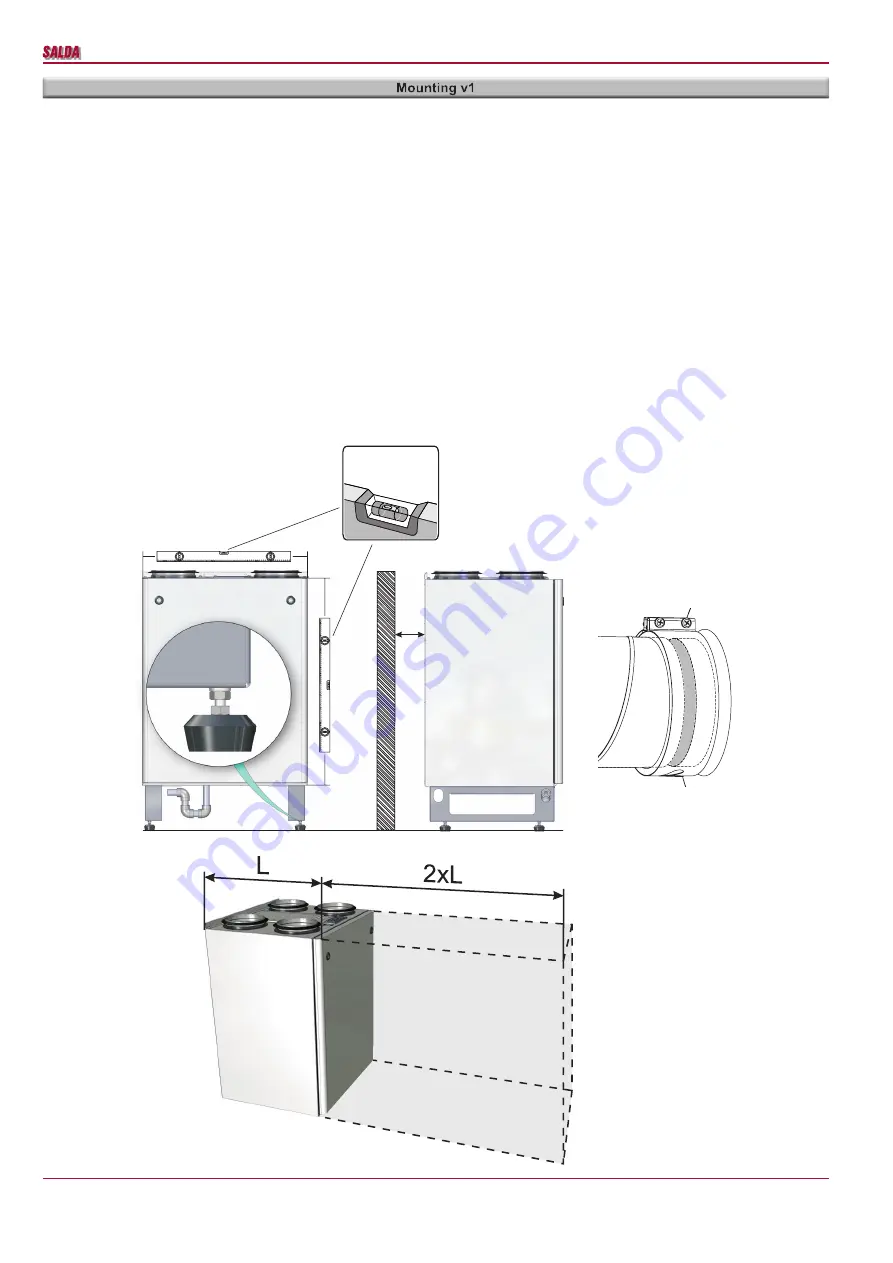

• Do not connect the elbows in vicinity of the connection flanges of the unit. The minimum distance of the straight air duct between the unit and the first

branch of the air duct in the suction air duct must be 1xD, in air exhaust duct 3xD, where D is diameter of the air duct.

• It is recommended to use the accessories/holders (Pic. 01) for connection of the fan to the air duct system. This will reduce vibration transmitted by

the unit to the air duct system and environment.

• Installation shall be performed in such manner that the weight of the air duct system and its components would not overload the ventilation unit.

• Enough space must be left during installation for opening of the maintenance door of the ventilation unit.

• If the installed ventilation unit is adherent to the wall, it may transmit noise vibrations to the premises even though the level of noise caused by the

fans is admissible. The installation is recommended at the distance of 400 mm from the nearest wall. If it is not possible, the installation of the unit is

recommended on the wall of the room where the level of noise is not important.

• Also, vibrations can be transmitted through the floor. If possible, additionally insulate the floor to suppress the noise.

• Pipes are connected to the heater in such way that they could be easily disassembled and the heater could be removed from the unit casing when

performing service or repair works.

• Supply air heater (EKA) and fresh air preheater (EKA NIS) must be installed not closer than 1 m from the device flanges.

• Install the supply air temperature sensor in the supply air duct. Supply air temperature sensor (TJ) must be installed behind all air handling equipment

(coolers, heater), and as far as possible away from them, or according to the limits of the sensor cable.

• For the usage of motion sensor (PIR) for the unit‘s control or for connection of smoke alarms (DJ), it is necessary to provide separate power supply.

There is no power supply possibilities for these accessories in unit‘s automation.

• Two pressure or one CO2 converter can be connected to unit‘s automation as attachments. Converters‘power supply (24VDC) is built into the auto-

mation.

• When using DX cooler we recommend to use the differential pressure rely for cooler protection (PS600).

• Device power cable (CEE7 / 7) with a plug must be installed in a visible and accessible place for easy disconnection from its socket.

Pic. 01

400mm

Pic. 02