4

Smarty 3X VE / Smarty 3X VE 3.0

www.salda.lt

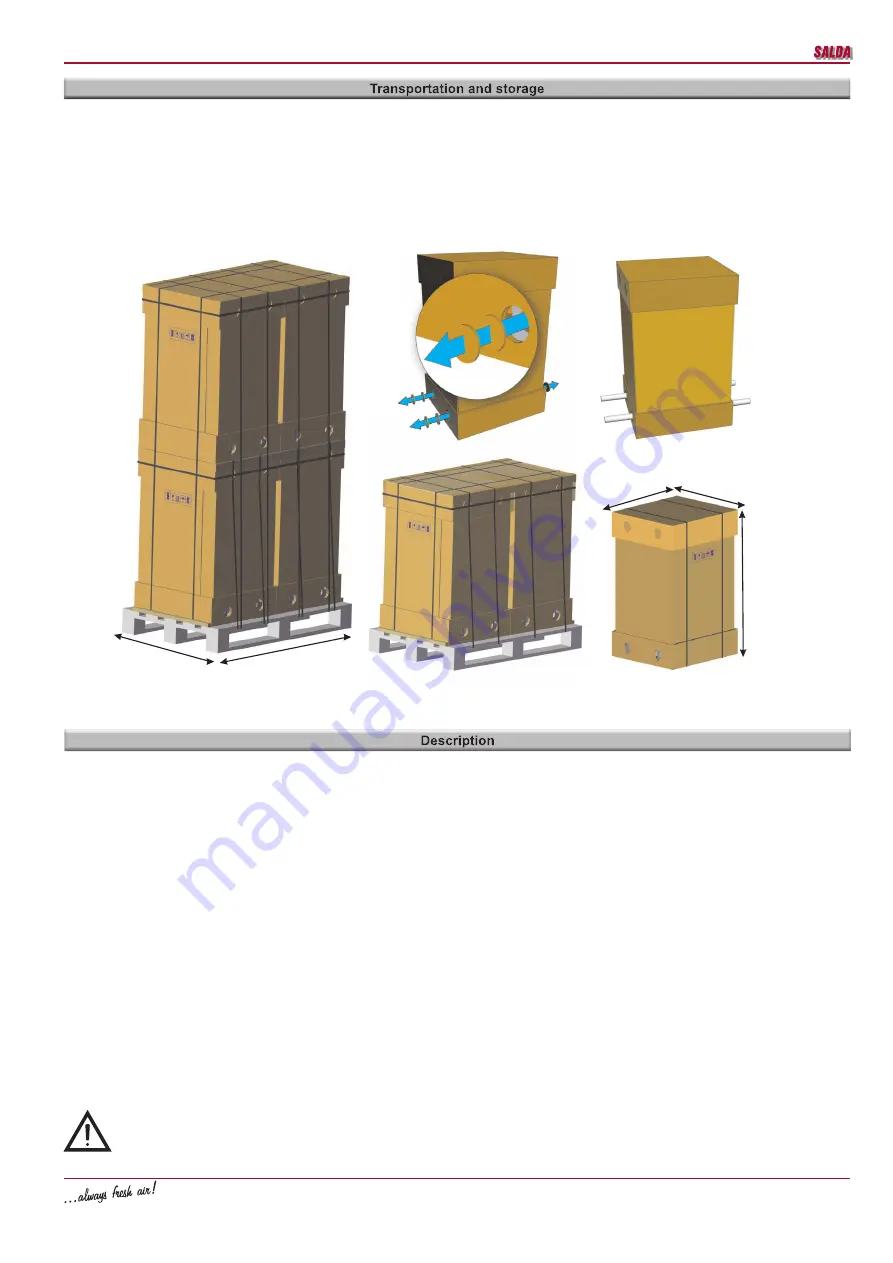

Preparation for transportation

800

1200

975

625

570

Air handling unit SMARTY 3X VE with plate heat exchanger (temperature efficiency up to 90 %) is designed to clean and supply fresh air. The unit

takes heat from exhausted air and transmits it to supply air.

MAIN FEATURES

Air flow ranges:

• Building protection

60 m³/h;

• Minimal

95 m³/h;

• Nominal

233 m³/h

• Maximal

333 m³/h

• Counter flow heat exchanger is made from aluminum and has the following dimensions: (WxHxD) 271 x 496 x 350 mm. Spacing between the plates

is 2 mm;

• Efficient and silent EC fans - type R3G190RC05-03 Sound Power Level LW 45 dB(A) (ISO 9614-2 or ISO3744);

• Low SFP (Specific Fan Power) level: ≤ 0.35 W/(h/m³);

• Housing is made of galvanized steel. Outer side of the housing - white powder coating - RAL 9016. Inner corners of the body separating the air flows

are sealed with a sealant material.

• 30mm acoustic and thermal mineral wool insulation of external walls; to maintain low leakage level the doors are covered by special sealing material

from foam.

• Integrated control automation, Plug & Play function;

• SMARTY 3X VE can be controlled with FLEX or Stouch control panels;

• Filter type corresponds to the requirements of LST EN 779:2013:

Extract – panel M5 (WxHxD) 435 x 175 x 25 mm

Supply – panel F7 (WxHxD) 435 x 175 x 25 mm

• Outdoor exploitation temperature

+5 °C to +40 °C.

Not suitable for swimming pools, saunas and other similar facilities.

• All units are packed in the factory to withstand regular conditions of transportation.

• The unit can be lifted using metal rods (Pic. 1). Rod diameter - 35 - 40 mm.

• Upon unpacking, check the unit for any damages caused during transportation. It is forbidden to install damaged units!!!

• The package is only for protection purpose!

• While unloading and storing the units, use suitable lifting equipment to avoid damages and injuries. Do not lift units by holding on power supply

cables, connection boxes, air extract or exhaust flanges. Avoid hits and shock overloads. Before installation units must be stored in a dry room with

the relative air humidity not exceeding 70% (at +20 °C) and with the average ambient temperature ranging b5 °C and +30 °C. The place of

storage must be protected against dirt and water.

• The units must be transported to the storage or installation site using forklifts.

• The storage is not recommended for a period longer than one year. In case of storage longer than one year, before the installation it is necessary

to verify whether the bearings of fans and motor rotate easily (turn the impeller by hand) and if the electric circuit insulation is not damaged or the

moisture is accumulated.

Pic. 1