FT TRUCK MT

19

Troubleshooting

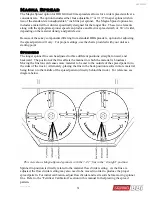

Here are some common results of spread pattern tests and how to correct them.

Pattern 1:

Two heavy swaths located directly behind the spinners; material is seen blowing

over the tops of the spinners.

Cause:

Spinner speed too fast, material blows over the tops of the spinners and falls to

the ground directly behind the unit.

Cure:

Decrease spinner speed.

Pattern 2:

Heavy on one side only.

Cause:

1. More material is being deposited on one spinner.

2. Material has collected on the divider panels.

Cure:

1.

Accurately

measure

the

position of the flow divider.

2. Keep divider scraped clean of material build-up.

Pattern 3:

Heavy in the center, no material exists ahead of fans.

Cause:

Divider is too far forward.

Cure:

Move divider toward rear.

Pattern 4:

Heavy at outer edges. Excessive material strikes front deflector panels.

Cause: 1.

Deflector

is too far rearward.

2. Spinner speed too fast.

Cure:

1. Adjust divider forward.

2. If adjusting flow divider does not fix problem, adjust spinner speed.

Pattern 5:

Good pattern

Cause:

Proper spinner and divider setting

Effect:

Material exits on arc from near spinner to front deflector. Pattern density tapers

off to nothing at outer 10% on each side of total spread width.

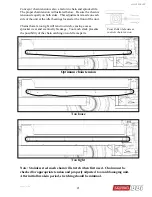

ACCURATE METERING OF FERTILIZER MATERIALS

Once an adequate spread pattern has been obtained, the spreader should be calibrated to deliver

the desired rate per acre.

Tables for determining the gate setting can be found on the spreader decal on the side of the

hopper. Many times an operator will set the gate according to the rate chart and be disappointed

when he comes up short or has product left over at the end of the field. This discrepancy is

usually caused by the miscalculation of the bulk density or weight per cubic foot. The

guesswork of estimating the weight per cubic foot of a blend can be eliminated with the use of

the weigh scale or weighing 7.5 gallons as previously discussed.

After the spreader has been successfully calibrated and tested, it is ready for use.

Remember to USE EXTREME CAUTION and FOLLOW ALL

SAFETY INSTRUCTIONS while operating this machinery.

ADJUSTMENTS