FT TRUCK MT

9

GENERAL OPERATING PROCEDURES

To operate the spreader, the following sequence should be observed:

1. Be sure the unit has been serviced and is in good operating condition.

2. Disengage the PTO.

3. Fill the body with material to be spread.

4. Drive to the location where spreading is to be done.

5. Adjust the unit’s hydraulic control valve (priority valve) to the setting required for the

material used, based on the desired spread pattern.

6. Adjust the material flow divider to provide proper delivery to spinners.

7. Set the feed gate opening to obtain the desired yield.

8. Engage the PTO

9. Drive at a speed that allows the engine to run at a proper RPM and maintain good control

for the terrain.

ADJUSTING YOUR SPREADER

IMPORTANT!

Spinner assembly and material flow dividers have not been

adjusted at the factory. Before spreading material, spread

pattern tests must be conducted to properly adjust the spreader.

THE MANUFACTURER OF THIS SPREADER WILL NOT

BE LIABLE FOR MISAPPLIED MATERIAL DUE TO AN

IMPROPERLY ADJUSTED SPREADER

.

It is recommended that spread pattern tests be conducted prior to each spreading season, after

any spreader maintenance, and periodically during the season. Spread pattern tests must be

conducted whenever a new product is to be applied.

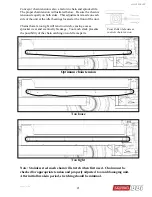

The spread pattern is affected by a variety of conditions including:

1. Spinner speed.

2. Point of delivery of material to the spinner dishes.

3. The condition of the fins on the spinner dishes (i.e. damaged, bent, broken, rusted, dirty,

etc.)

4. Material granule size.

5. Material flow characteristics.

6. Material weight per cubic foot.

7. Rate of delivery of material.

8. Balance between deliveries to both spinner dishes.

9. Cleanliness of the fins and the dishes themselves.

10. Level of spreader.

11. Wind.

Because most of these characteristics will change with each load of material being spread, a

certain amount of experience mixed with some testing will determine the adjustments needed to

obtain the spread width and pattern desired. Detailed information is provided in later sections on

how to read the conditions you have and how to make changes to get the spread pattern you

need.

BASICS